Cashco 521 User Manual

Page 2

IOM-521

2

III. INSTALLATION

A. Orientation

1. Recommended orientation when installed is

in a hor i zon tal pipeline with the stem verti-

cal. Valves may be installed in a vertical or

hor i zon tal pipeline with the stem between

vertical and horizontal.

2. Outdoors, all installations may be oriented

at any angle from horizontal-to-vertical, as

per A.1. above.

3. Model 521 valves should not be installed

with the stem oriented below horizontal/

down wards.

4. In no case is additional weight to be applied

to the actuator assembly when installed in

an ori en ta tion other than vertical.

8. Undue piping stress/strain or bending

torques may not be transmitted thru the

control valve body. One pipe (inlet or outlet)

should be anchored rigidly for piping that

is “hot” or “cold” with respect to ambient

SECTION III

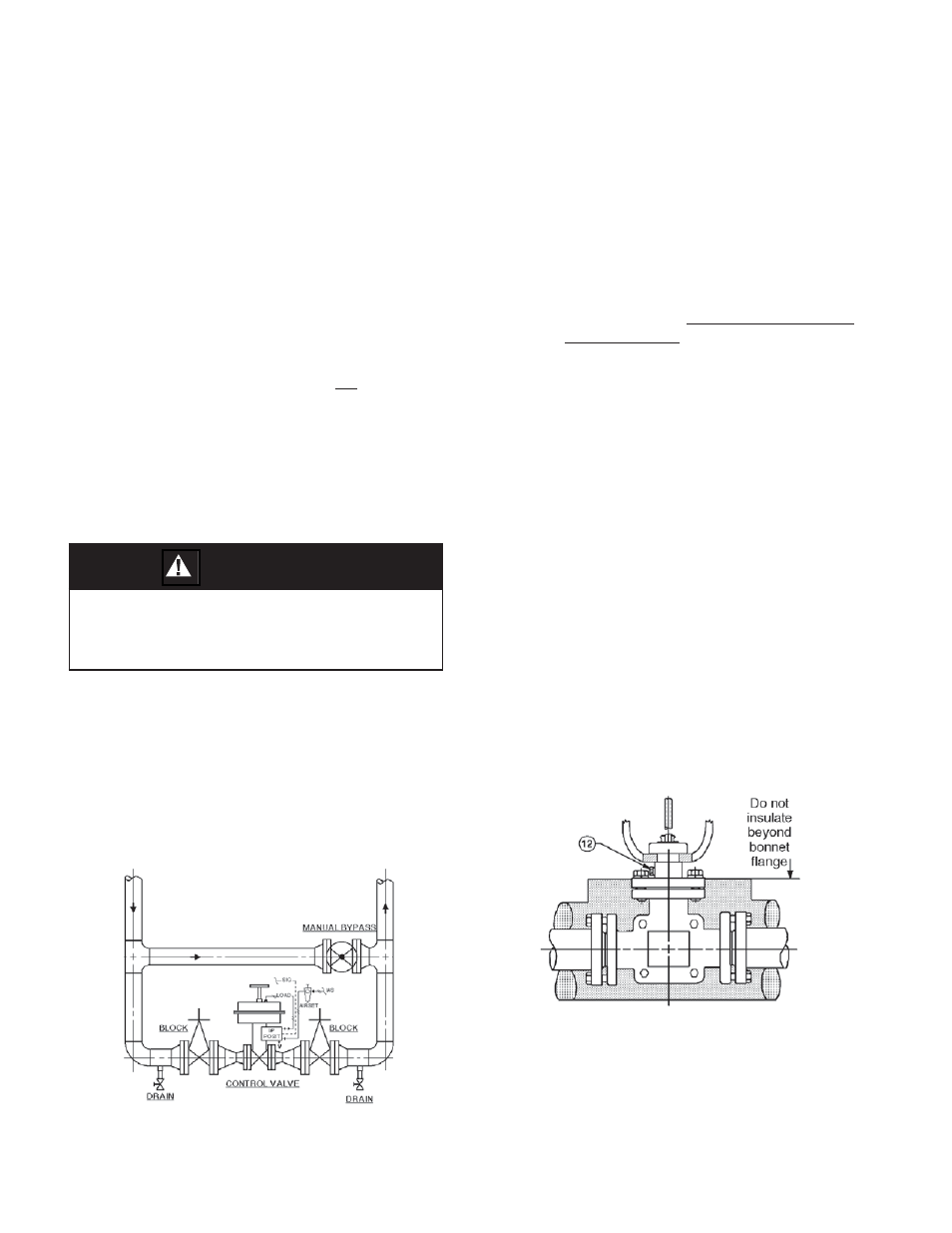

Figure 2: Body Insulation

B.

Piping

System

1. It is recommended that the control valve unit

be installed with a double-block and bypass

as indicated in Figure 1. This arrangement

is recommended especially where main te-

nance will be done on the valve body while

still installed in the pipeline.

2. If pipe reducers are located before and/or

after the valve body, keep the reducers as

close as practical to the valve body; this is

especially important where the reducers are

more than one line size larger than the valve

body size, which is common in gaseous

ser vice.

3. Clean the piping of all foreign debris, in-

cluding chips, weld scale, weld splatter,

oil, grease, sand or dirt prior to installing

the control valve; THIS IS AN ABSOLUTE

REQUIREMENT.

4. Field hydrostatic testing the completed

piping system, including the Model 521,

to 1-1/2 x CWP in di cat ed on Model 521

name plate is ac cept able. If hydro test pres-

sure ex ceeds the 1-1/2 x CWP limit, the 521

must be re moved for such testing. Before

pres sur iza tion, the valve plug should be

lifted from the seat if of re verse, ATO-FC

action.

5. Flow Direction: Install so the fl ow direc-

tion match es the arrow cast on the valve

body.

6. Valves are not to be direct buried un der -

ground.

7. Insulation may be applied as indicated in

Fig ure 2. Drainage from the packing area

must be ensured when fully installed, sealed

and lagged for outdoors installation. Vented

pipe plug (12) should not be covered.

WARNING

The valve/actuator unit should not be used as a

“step” to sup port per son nel. Failure to comply

may cause leak age at the bonnet/body joint, al-

low ing pos si ble con tact with harm ful fl uids.

Figure 1: Typical Control Valve Station