Cashco 521 User Manual

Page 6

IOM-521

6

6. Loosen stem nut (20) by rotating nut CW

(viewed from above) to base of threads.

7. Loosen packing (6) by turning packing gland

nut (5) CCW 2-3 revolutions.

8. Rotate yoke nut (15) CCW to fully loosen

nut.

9A. For ATO-FC Reverse Action Actuators:

a. Connect a temporary air source

to the actuator and pressurize the

actuator to upper limit of the bench

range specifi ed on the valve name

plate. (Pressure will lift the plug head

(3) away from the body's (1) integral

seat until the plug (3) is 100% open.)

b. Place a wrench on the hex surface of

the swivel lower knuckle (44) and rotate

knuckle CCW (viewed from above ac tu a-

tor) until lower knuckle dis-engages from

stem (9). Keep track of the number of

full rev o lu tions to dis-engage and record

here. _______________

c. Maintain lift support from above the

7. For units with Reverse Action (ATO-FC)

ac tu a tors pressurize to a level suffi cient to

initiate travel to approximately mid-stroke

to hold the plug (3) away from the body (1)

seat.

8. Apply

leak

detection

fl uid to all the potential

leak paths:

a. Packing gland nut (5). (Tighten as nec es-

sary.)

b. Body (1)-to-bonnet (2) fl ange tape hole.

c. Body (1) and bonnet (2) bolting (13, 14,

1.3, 1.4, 1.5).

d. End connection blind fl ange tape hole.

e. Test pressure piping con nec tions.

9. If leakage occurs at:

a. a. above, there is a packing (6) or a pack-

ing (6) /stem sub-assembly (9) failure.

b. b. above, there is a bonnet gasket (11)

failure.

c. c. above, there is a bonnet gasket (11),

or TFE core (1.2) failure.

d. d. above, there is a bellows sub-as sem bly

(8) failure.

10. Following this test procedure may help

to solve main te nance problems when

combined with visual ex am i na tion of disas-

sembled body assembly (BA).

C. Separation of Body/Actuator:

1. Reference the Actuator IOM-C27-C53 for

item number call outs and drawings for

actuator.

2. Secure the body in a vise with the actuator

assembly (AA) oriented vertically. Place

matchmarks between the body (1) bon net

fl ange, the bonnet (2) fl ange, and the yoke

(3) to assist in fi nal ori en ta tion when the

body is dis as sem bled and/or the ac tu a tor

removed. If actuator has handwheel - see

Actuator IOM for removal instructions.

3. Secure and rig the actuator assembly (AA)

for a ver ti cal lift using an overhead hoist.

Remove slack from rigging.

4. This procedure assumes that the body as-

sem bly (BA) has been fully assembled thru

the bonnet (2), including the packing gland

nut (5) and packing (6).

5. Remove vented pipe plug (12) from body.

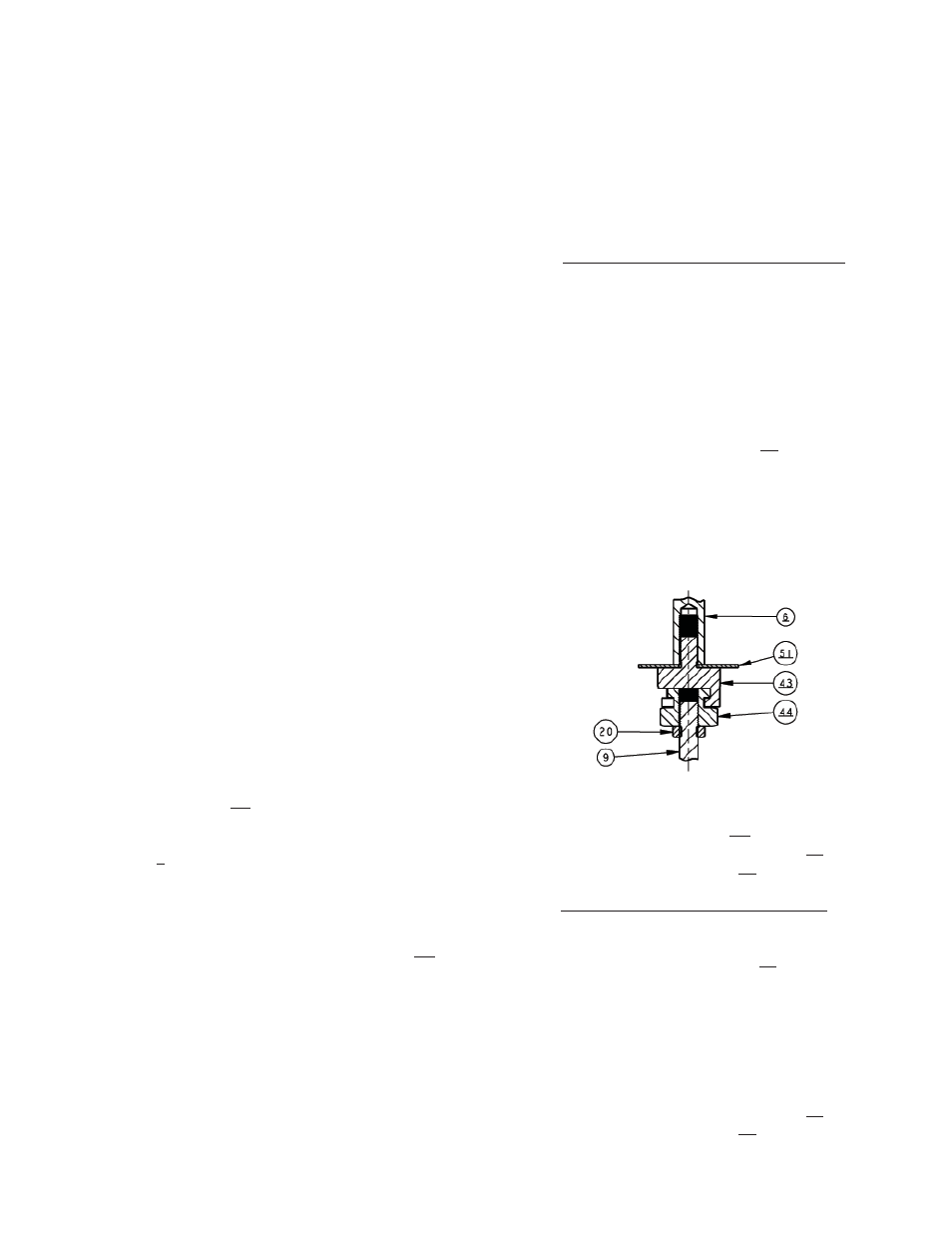

Figure 6: Swivel-Type Connector

actuator assembly (AA). Dis-engage

(slide) the swivel lower knuckle (44) out

of the upper knuckle (43) slot.

9B. For ATC-FO Direct Action Actuators:

a. Place a wrench on the hex surface of

the swivel lower knuckle (44) and rotate

knuckle CCW (viewed from above ac tu a-

tor) until lower knuckle dis-engages from

stem (9). Keep track of the number of

full rev o lu tions to dis-engage and record

here. ________________

b. Maintain lift support from above the

actuator assembly (AA). Dis-engage

(slide) the swivel lower knuckle (44) out

of the upper knuckle (43) slot.