Cashco 964 User Manual

Page 9

IOM-964

9

Number of revolutions to disengage

valve stem from actuator stem:

c. Using soft-jawed pliers, grasp the stem

(3) just below/at the threaded por tion,

and rotate the stem/plug assembly (3)

CCW (viewed from plug end) to re mov al.

Record the num ber of rev o lu tions re quired

to dis en gage in box below:

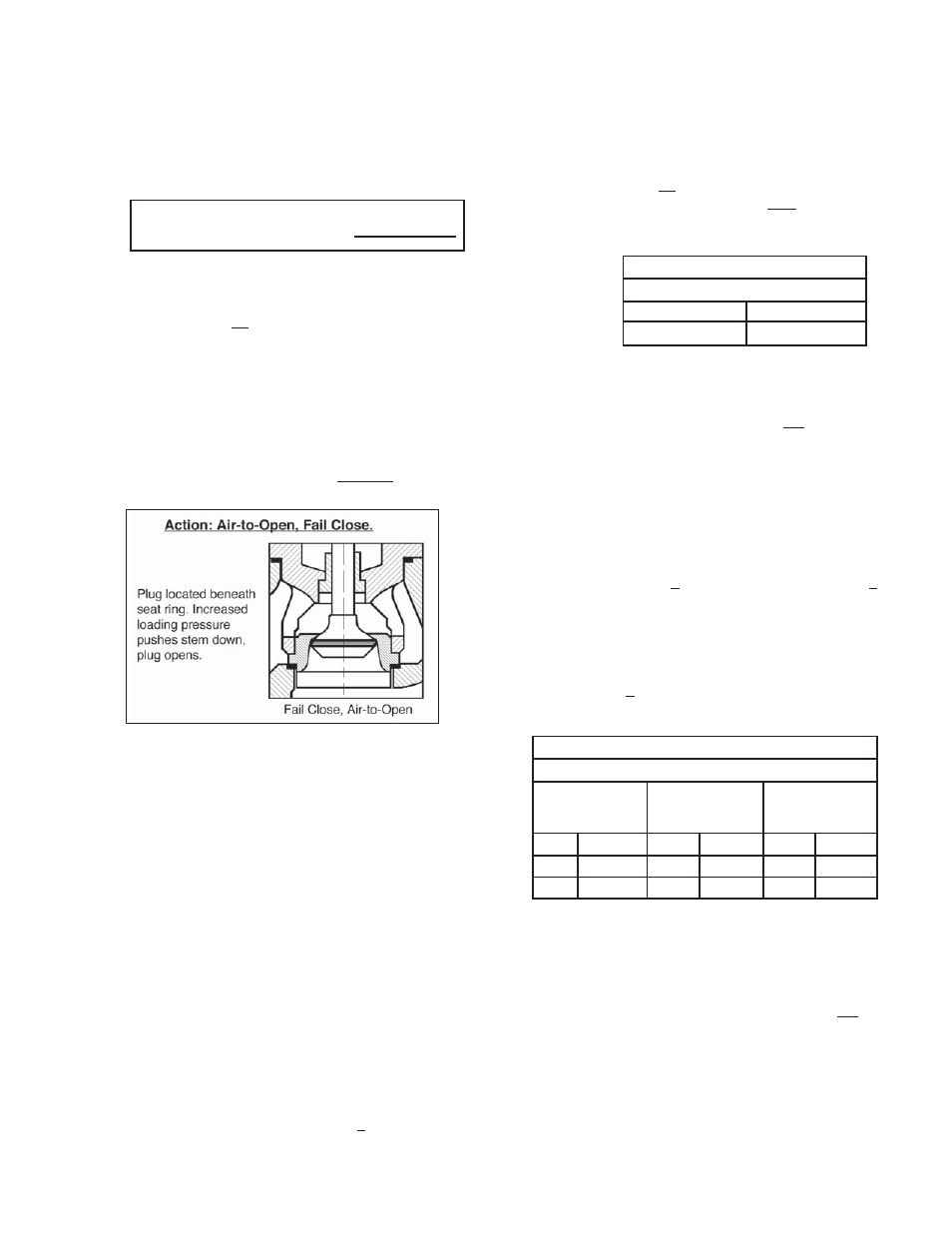

Figure 6: ATO-FC Action

TABLE 1

No. of Stem Revs to Add/Subtract

ATO-FC to ATC-FO

ATC-FO to ATO-FC

+ 6

- 6

d. Partially withdraw the stem/plug as sem bly

(3) from the bonnet (2), taking care not to

drop the seat ring (11), position in di cat ing

disc (20) and ac ces so ry plate ((AP)), if

in stalled.

e. Remove jam nuts (18). Fully with draw stem/

plug as sem bly (3) from the bon net (2).

f. Clean gasket facing sur fac es and in stall

a new seat ring gasket (13) in the body

(1) cavity. Set the seat ring (11) into the

body (1) cavity in an inverted ori en ta tion

from the way re moved.

g. Place a new bonnet gasket (12) in the

body (1) recess.

h. Remove and replace packing rings (6) as

directed else where in this sub-sec tion,

if de sired.

i. Insert the stem/plug assembly (3) back

into the bottom of the bonnet (2). Screw

both jam nuts (18) back onto stem (3),

and locate at the root of the thread por-

tion. Re place all the “loose dan gling”

parts back in their proper order and

ori en ta tion.

NOTE: Reference the IOM for the po si tion er, as

the orientation/location of the ((AP)) may change.

If the action of the po si tion er does not change

when the valve unit’s action is changed, the lo-

ca tion of the po si tion er unit will change from the

right side of the ac tu a tor yoke (1) to the left side,

or vice versa. This requires that the ac tu a tor be

rotated 180 ° from the be gin ning body-to-bon net

ori en ta tion, and that the po si tion er be re moved

and reoriented to an op po site po si tion.

j.

Engage valve stem (3) with the ac tu a tor

stem (19) with the num ber of rev o lu tions

recorded in Step 7.c, plus the num ber

of revs in di cat ed in Table 1.

TABLE 2

ATO-FC CONVERTED TO ATC-FO

Bench Set

Indicated

on Nameplate

New Bench

Set to be

Utilized

Loading

Pres sure for

Step 7.p.

psig

(Barg)

psig

(Barg)

psig

(Barg)

5-15

(.34-1.0)

3-13

(.21-.90)

13

(.90)

9-30

(.62-20.7)

6-27

(.41-1.9)

27

(1.9)

k. Tighten one jam nut (18) into po si tion.

l. Lift actuator assembly (AA) and low er

into the body (1) cavity, aligning over

bon net studs (16). Rest the bonnet (2)

onto the bonnet gasket (12).

m. Install nuts (17) onto bonnet bolt ing (16).

Hand tighten; loosen one rev o lu tion.

n. Replace compression to actuator range

spring (6) by ro tat ing spring adjustor (4)

CW (viewed from plug end) the number

of revs in di cat ed in the table of Step 3

pre vi ous.

o. Slowly pressurize the ac tu a tor cas ing

(2) to the higher level of the bench set

in di cat ed in Table 2.

p. Observe that the bonnet (2) rises as the

plug head (3) pushes against the seat

ring (11).

q. Wiggle the actuator assembly (AA) to

align all the moving parts. Wrench-

tight en the bon net bolting nuts (17) in

alternating cross-pat tern and in 1/2 rev o-

lu tion in cre ments until fully tightened.

r. Release air pressure in actuator and

pro ceed to Step 9.