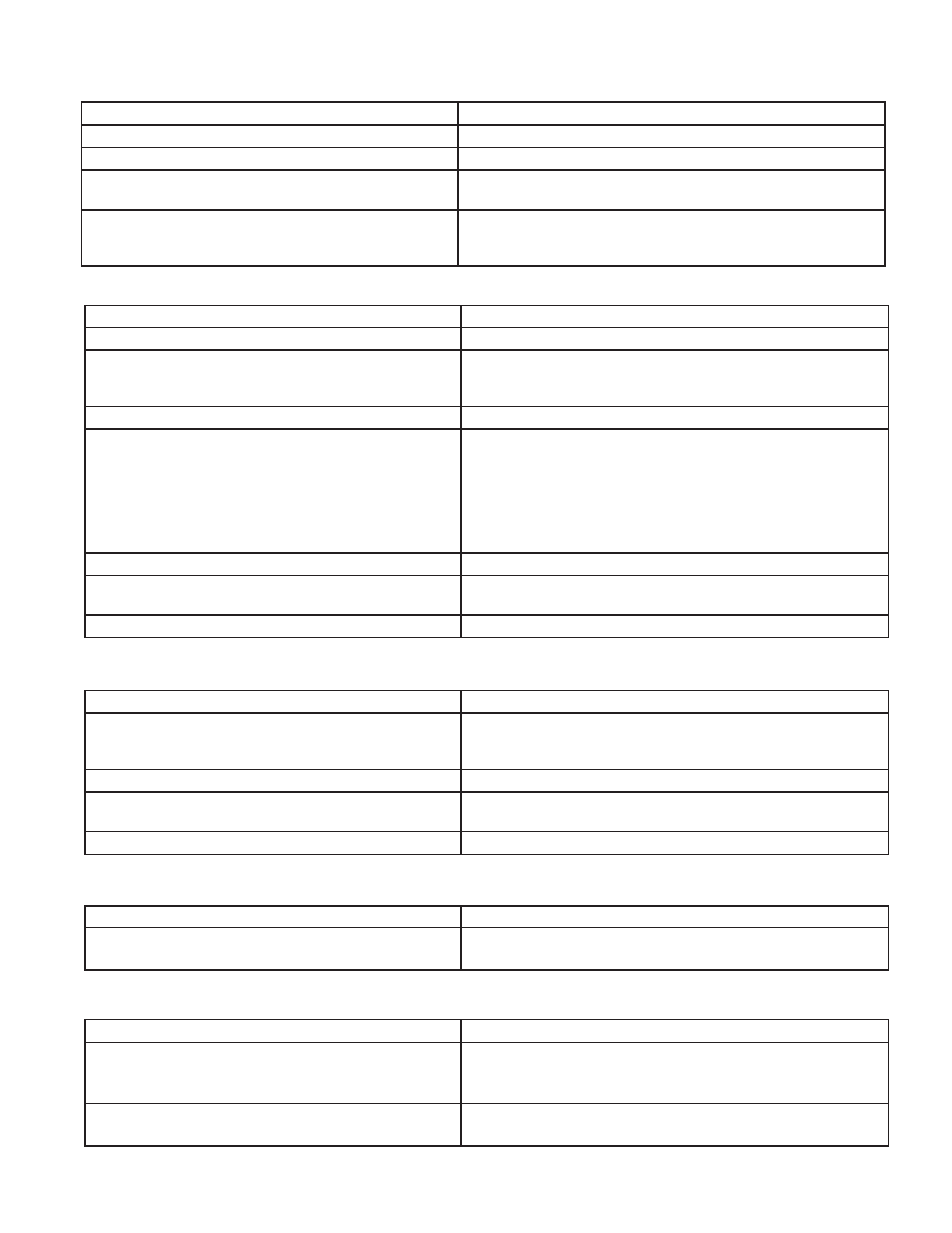

Cashco 964 User Manual

Page 15

IOM-964

15

Possible Causes

Remedies

A.

Excess pressure drop.

A.

Bring pres sure drop within design limits.

B.

Guide bushing wear.

B.

Re place guide bushing.

C. Excessive cavitation in liquid service.

C1.

C2.

Change operation parameters to relieve causes of cavitation.

Replace valve with valve equipped for cavi ta tional control.

D. High outlet velocity.

D1.

D2.

D3.

Re duce fl ow rate and/or pressure drop.

Use multiple valves in series or parallel.

Increase outlet pipe size.

3. Valve exhibits “excess” vibration.

Possible Causes

Remedies

A.

Excess pressure drop.

A.

Re duce pres sure drop conditions.

B.

Improper actuator bench setting.

B1.

B2.

Cali brate actuator-to-valve.

Assure proper engagement of actuator stem-to-valve stem.

Adjust as calibration dictates.

C. Metal seat design instead of composition seat design. C.

Convert valve to composition seat design.

D. Excess wear.

D1.

D2.

D3.

D4.

D5.

Oversized valve op er at ing too close to seat; go to reduced trim.

Incorporate stellite trim.

Remove particulate.

Possible excess cavitation in liquid service. Change operation

parameters.

Re-lap plug-seat surface.

E.

Misalignment.

E.

Realign body - stem - actuator.

F.

composition seat failure.

F1.

F2.

Replace soft seat.

Remove "dirty" portion of fl uid causing failure.

G. Seat ring gasket failure.

G.

Replace seat ring gasket.

4. Valve exhibits “excess” seat leakage.

Possible Causes

Remedies

A.

Over-temperature.

A1.

A2.

Bring process temperature to 450°F (232°C) or less.

Remove in su la tion along bonnet; al low di rect con tact with

ambient air.

B.

Misalignment.

B.

Realign body - stem - actuator.

C. Wear.

C1.

C2.

Remove dirt/grit from fl uid.

Reduce cyclic travel.

D. Improper design for applied service.

D1. Install alternate packing design.

5. Premature packing leakage.

Possible Causes

Remedies

A.

Improper bonnet bolting draw down.

A1.

Replace gasket and draw down bolting evenly in a

cross-pattern.

6. Bonnet gasket leaking.

Possible Causes

Remedies

A.

Over-tightening fl ange bolting.

A1.

A2.

Loosen bolting, replace gasket, reinstall new fl ange

bolting.

Replace warped fl ang es.

B.

Improper pipe supports and anchors.

B.

Provide piping anchors and guides at control valve sta-

tion. Restrain bending movements.

7. Body

fl ange leakage.