Cashco 964 User Manual

Page 11

IOM-964

11

TABLE 4

Body Size

Number of Packing

Rings

inches

(DN)

2

(50)

9

3

(80)

9

the fl ow tending to push the plug open - FTO,

re gard less as to ATO-FC or ATC-FO ac tions.)

11. Wrench tighten packing to a min i mum of 12 ft/

lbs (16 N-M) torque. (NOTE: Field tight en ing

may be required to seal leak age.)

12. Tighten second jam nut (18).

H. Packing Replacement:

1. This requires that the ac tu a tor stem (19) be

sep a rat ed from the valve stem (3) to re place

pack ing (6).

4. Loosen screws (22) and po si tion the in di ca-

tor plate (21) at “S” (for shut); tight en screws

(22) to se cure in di ca tor plate (21). (NOTE:

Set the indicator plate (21) at the top edge

of the in di ca tor disc (20).)

5. Reference

the

name

plate

(12) at tached to the ac tu a-

tor yoke (1). De ter mine

the bench set ting of the

in stalled range spring (6)

from the name plate (12);

i.e. 5-15 psig (.34-1.0

Barg), or 9-30 psig (.62-2.1

Barg).

6. Pressurize the actua-

tor to a pres sure level

2-3 psig (0.1-0.2 Barg)

above the upper pres sure

level of the bench set ting:

i.e. for 5-15 psig (.34-1.0

Barg) range, set pres sure

at 17-18 psig (1.2-1.3

Barg).

V. CALIBRATION

A. General:

1. This section covers cal i bra tion of the con trol

valve unit. Cal i bra tion consists of ad just ing

stroke length and bench set ting.

2. Positioner, if installed, re quires ref er ence to

the spe cifi c po si tion er model IOM for prop er

cal i bra tion pro ce dure.

3. All indicated Item Num bers that are with re-

spect to IOM-964 and are part of “body” will

be in single pa ren the sis; i.e (2). Those that

are part of the 964 actuator will be in single

pa ren the sis and un der scored; (2). Those that

are part of the po si tion er IOM will be in double

pa ren the sis; i.e. ((AP)).

4. Following procedures assumes as sem bled

valve unit has been removed from the pipe-

line where installed and all main te nance has

been com plet ed per in struc tions of Sec tion IV

preceeding.

B. Procedure – Reverse Action, ATO-FC:

1. Place body (1) in a vise with ac tu a tor as sem bly

(AA) directed upwards.

2. Connect a temporary air supply with an in-line

ad just able airset regulator with gauge to the

actuator top works con nec tion.

3. Loosen lower stem jam nut (18) by ro tat ing

CCW (viewed from plug end) 2-3 rev o lu tions.

Using upper stem jam nut (18), fi rmly lo cate

the in di ca tor disc (20) up against the ac tu a tor

stem (19) bot tom.

7. Observe the position of the in di ca tor disc

(20) on the scale of the in di ca tor plate (21),

making sure to use the “top edge” of the

in di ca tor disc (20) as the ref er ence point. If

the position in di cat ed is not exactly at “O” (for

“open”), then the valve stem (3)-to-ac tu a tor

stem (19) com bined length is in cor rect, and

must be ad just ed.

8. a. If travel indicator stops above the “O”

po si tion, the com bined stem (3, 19)

length is short. Loos en jam nut (18)

hold ing the in di ca tor disc (20) against

ac tu a tor stem (19).

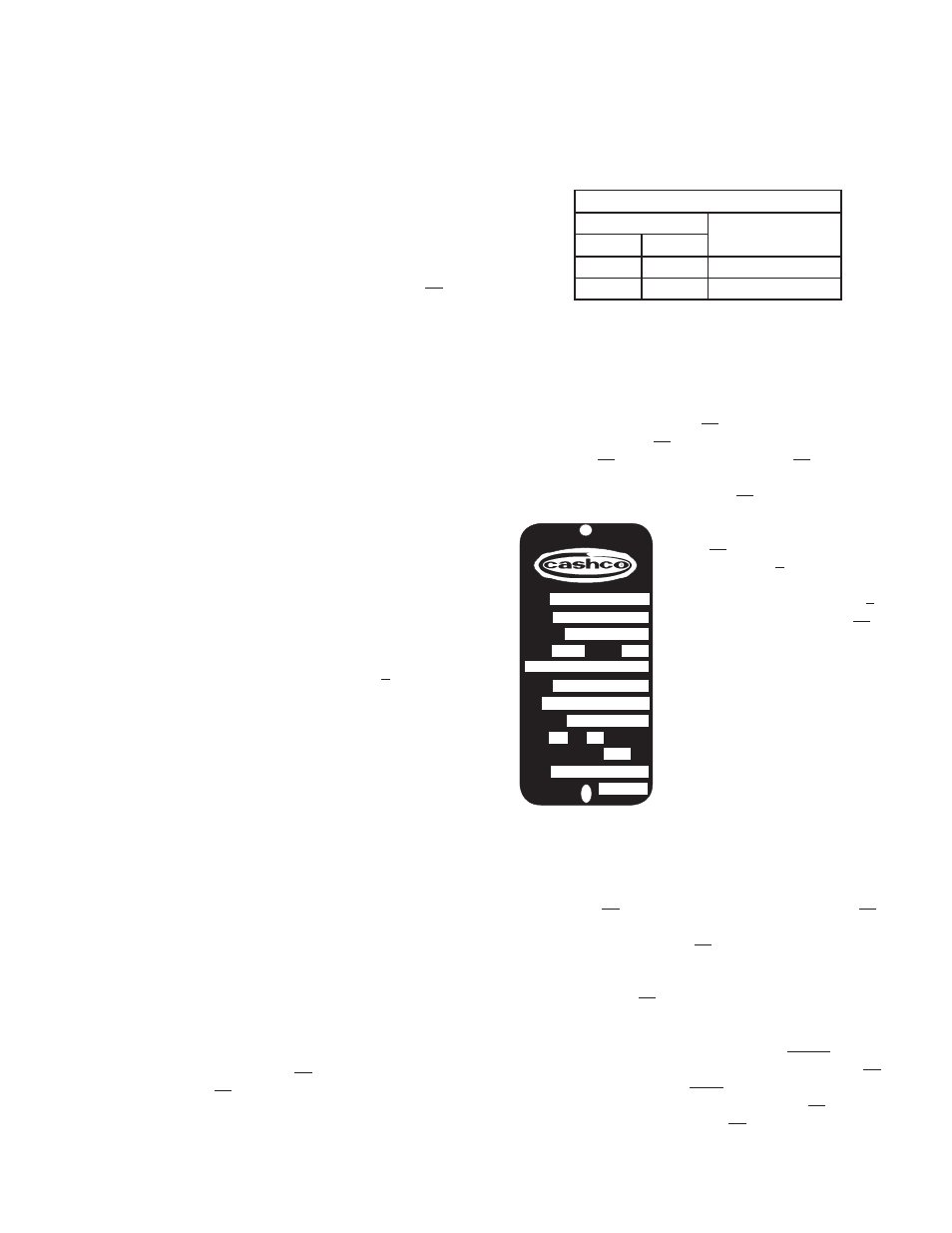

SN

SIZE

MODEL

FAIL

TRIM

Cv

BENCH

ACT.

MAX WORK ∆P

TAG

STROKE

BODY

psig Max

IN

2

SECTION V

2. Follow procedure in Steps IV. D.1 through

IV. D. 15., and Steps IV. D. 24. through 39.

3. The number of packing rings (6) is as re-

cord ed in Table 4 below: