Caution – Cashco 964 User Manual

Page 14

IOM-964

14

VII. TROUBLE - SHOOTING GUIDE

SECTION VII

Hereafter, the procedure as sumes that ac tu al

fl uid fl ow may be established. This may not

be practical / pos si ble in all cas es; if so, vary

procedure as re quired.

3. Start with either of the two block valves closed,

with the other open. The bypass valve should

be closed. Pres sur ize sys tem, if pos si ble/

prac ti cal.

4. Back out the airset’s adjusting screw until

loose.

5. Turn on air supply pressure.

6. Adjust the air supply airset (fi l ter-reg u la tor) to

the proper lev el as in di cat ed in the following

table.

NOTE: DO NOT STROKE THE CON TROL VALVE WITH

AN AIR SUP PLY PRES SURE SET TING GREAT ER THAN

REC OM MEND ED MAX I MUM PRES SURE!

7. Place loop controller into “man u al” mode. Vary

setting from minimum - mid-range - max i mum

SIG output. Ob serve re sponse of con trol

valve unit to these chang es of input SIG. The

valve should fully stroke at the vari a tion from

min i mum SIG to max i mum SIG; the mid-range

SIG should have the valve stem travel at/near

1/2 open.

8. Confi rm that action of con trol ler and po si tion er

- direct or reverse - are producing the de sired

re sponse in the con trol unit. Con fi rm that the

con trol valve “fail” po si tion is as re quired.

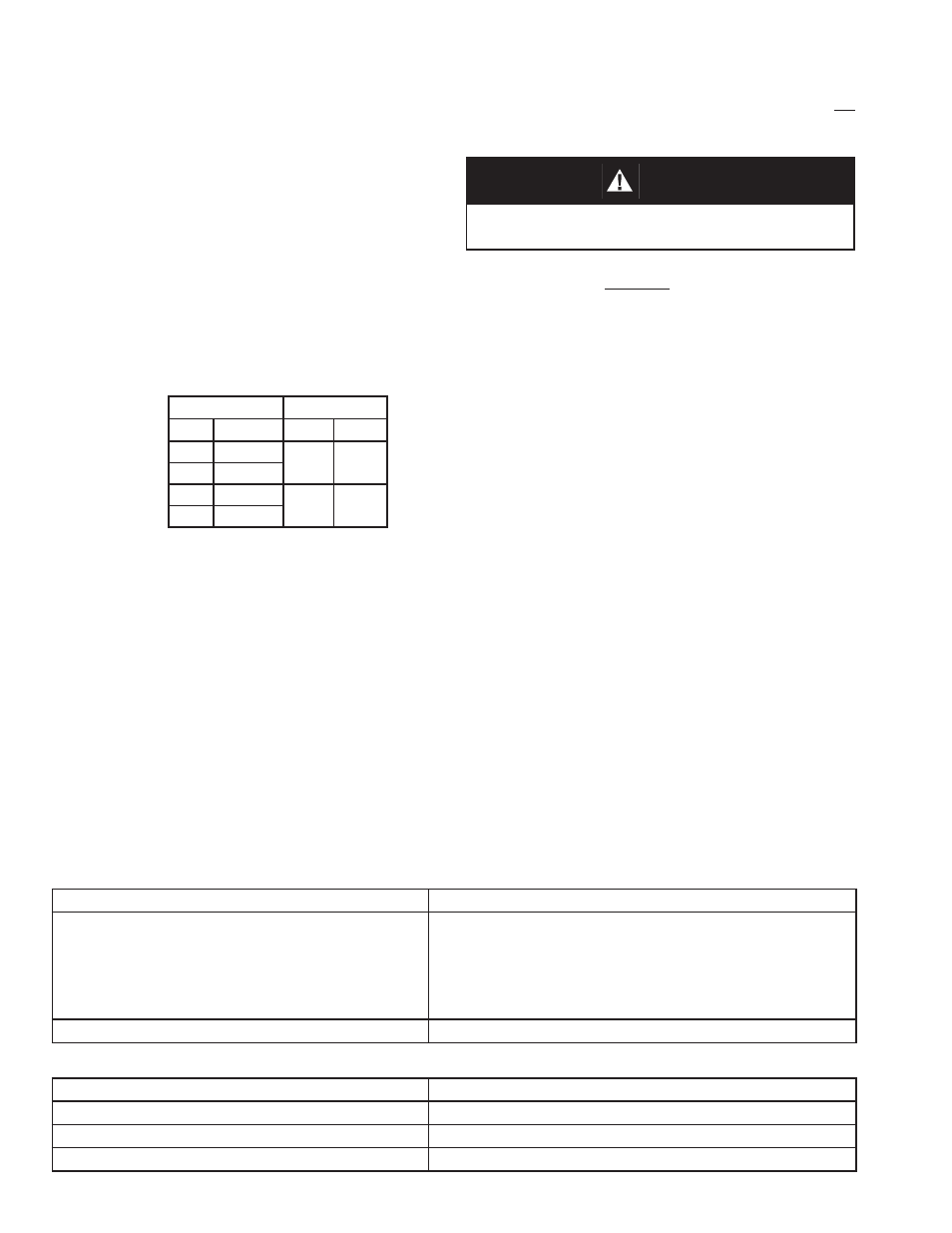

Bench Setting

Airset Output

psig

(Barg)

psig

(Barg)

5-15

(.34-1.0)

20

(1.4)

3-13

(.21-.90)

9-30

(.61-2.1)

35

(2.4)

6-27

(.41-1.9)

CAUTION

DO NOT WALK AWAY AND LEAVE A MAN U AL LY

CONTROLLED CON TROL VALVE UN AT TEND ED!

Possible Causes

Remedies

A.

Excess packing friction.

A1.

A2.

A3.

A4.

A5.

Realign body - stem - actuator.

Packing follower too tight for optional packing designs.

Install positioner.

Increase bench set by changing to stiffer actuator range

spring. Will require positioner if not installed. May require

different airset.

B.

Installed backwards.

B.

Install per fl ow arrow.

1. Valve is “jumpy” in stroking.

Possible Causes

Remedies

A.

Excess pressure drop.

A.

Bring pressure drop within design limits.

B.

Guide bushing wear.

B.

Re place guide bushing.

C. Misalignment.

C.

Realign body-stem-actuator.

2. Valve makes “screeching” noise.

9. Always “heat” or “cool” down the system

pip ing SLOW LY by open ing the control valve

sta tion by pass valve in small in cre ments.

10. With one of the control valve station block

valves still closed, and the loop con trol ler

still in “man u al” mode, open by pass valve

and vary fl ow rate man u al ly to ob serve the

re sponse of the con trol ler and control valve

unit to geth er.

11. Attempt to develop manual con trol of the

loop by opening/clos ing the man u al by pass

as re quired, or by manually con trol ling main-

stream fl ow as re quired.

12. When control valve is partially open, crack

open slowly the closed block valve while

si mul ta neous ly clos ing the by pass valve.

Con tin ue this pro ce dure until the bypass is

closed and the block valves are both fully

open. The system is still under “man u al”

mode control, but all fl ow is pass ing through

the control valve.

13. Vary controller “manual” SIG output until

match ing the “au to mat ic” SIG output, then

change the mode of the controller over to

“automatic”, and the loop will ex pe ri ence a

min i mum of upset con di tions, and will be in

au to mat ic control.