Cashco 964 User Manual

Page 6

IOM-964

6

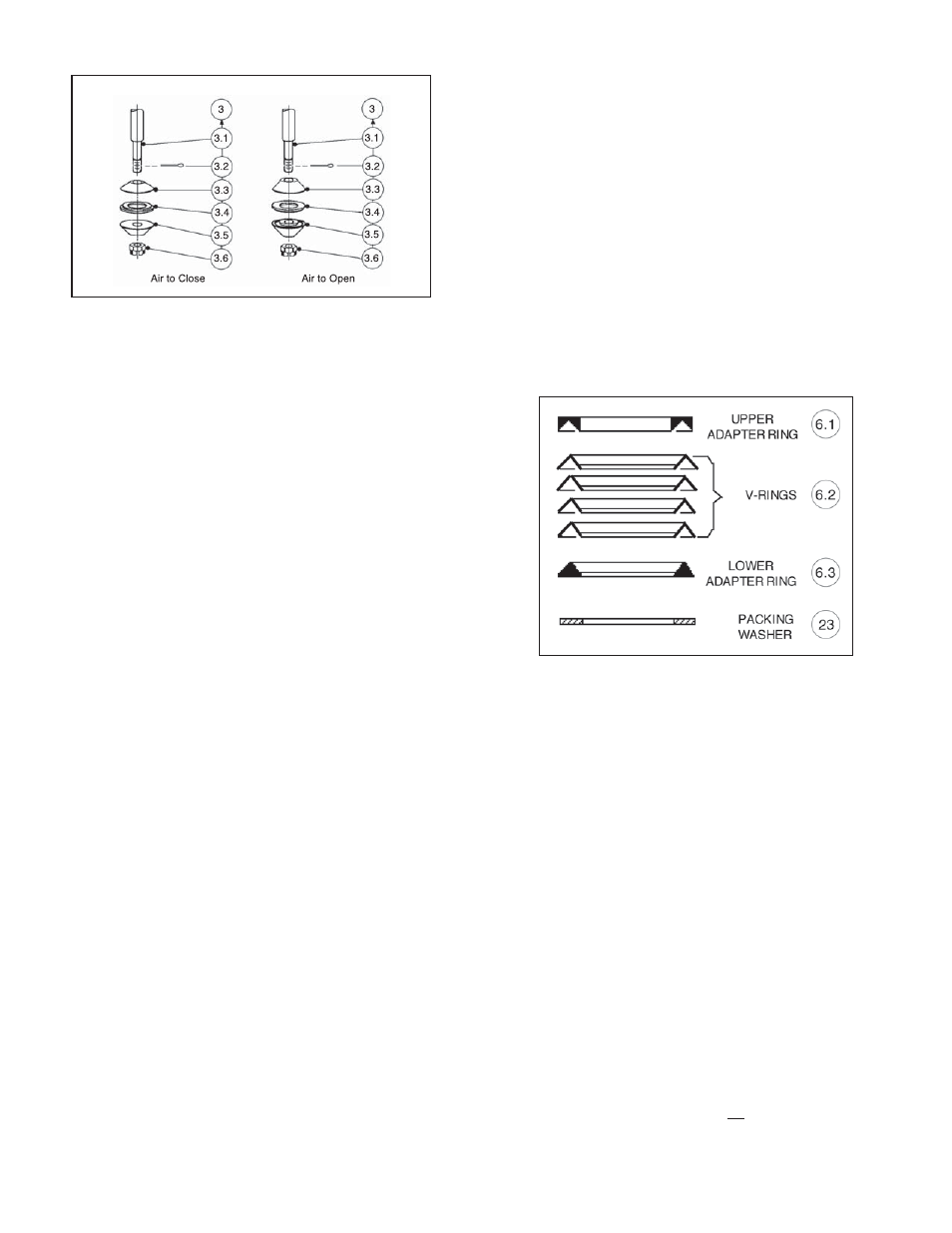

Figure 3: Composition Seat Ar range ment

a. Examine stem (3) in critical fi nish zone

where contact is made with the packing

(6). It is desirable to restore the surface

of the stem (3) to a #8 Ra μ-in surface

fi nish; metal removal should not exceed

0.001-inch material. A deeply scratched

or pitted stem (3) should be replaced.

b. Plug head of stem (3) assembly for metal

seated design may be hand lapped us-

ing suitable lapping com pound. If hand

lap ping will not restore surface fi nish to

an ac cept able de gree, the re place ment

of stem (3) as sem bly and seat ring (11)

is rec om mend ed.

c. For composition seated design, the TFE

valve seat (3.4) can be replaced if the

adapt ers (3.3/3.5), cotter pin (3.2) and

castle nut (3.6) are not wear dam aged.

Grip stem (3.1) in vise (using pro tec-

tive cov er ing (directly above (3.3/3.5)

adapter ). Re move cot ter pin (3.2), castle

nut (3.6), adapt er (3.3 or 3.5) and valve

seat (3.4). Insert new valve seat (3.4) and

re as sem ble to desired seat ar range ment.

See Fig ure 3.

18. Examine the inner surface of the bonnet’s

(2) stuffi ng box. It is desirable to restore the

surface of stuffi ng box to a #16 Ra μ-in sur-

face fi nish; metal removal should not exceed

0.001-inch material. A deeply scratched or

pitted bonnet (2) should be replaced.

19. Examine packing follower (5) for corrosion.

Replace if signifi cantly corroded:

a. Remove follower bushing (25) from inside of

packing follower (5) and replace with new.

20. Remove

gaskets

(12) (13), clean gas ket fac ing

sur fac es and replace with new gas kets (12) (13).

21. For ATO-FC action units, place seat ring (11)

over end of stem (3) in proper ori en ta tion, and

insert the stem (3) until it ap pears thru the top

side of the bonnet (2). See Figure 6.

22. For ATC-FO action units, place seat ring (11)

into the body (1) cavity. Insert the stem (3) until

it ap pears thru the top side of the bonnet (2).

See Figure 7.

23. Lower packing spring (24) into bonnet (2)

pack ing box.

24. Lower packing washer (23) into bonnet (2)

packing box. Ensure that wash er (23) is rest-

ing fl at on the packing spring (24).

Figure 4: Packing Orientation

25. See Figure 4 for proper packing orientation.

a. Carefully place lower adapter (6.3) of

packing ring set (6) over stem’s (3) end,

properly oriented. Using the packing fol-

lower (5), push the lower adapter into the

bonnet’s (2) stuffi ng box.

b. Carefully place a packing ring (6.2) prop-

erly oriented over the stem’s (3) end and

push into the stuffi ng box similar to the

adapter (6.3). Repeat to each of the four

rings (6.2).

c. Carefully place upper adapter (6.1) over

the stem’s (3) end.

26. Slide packing follower (5) with new follower

bushing (25) over end of stem.

27. Place packing fl ange (4) over end of stem (3)

and over packing studs (14).

28. Slide position indicator disc (20) and accessory

plate ((AP)), in installed, over end of stem (3).