Vii. maintenance, Warning – Cashco SA1 User Manual

Page 3

IOM-CA1/SA1

3

VII. MAINTENANCE

A. General:

1. The regulator may be serviced without re mov-

ing the regulator from pipeline. The reg u la tor

is designed with quick-change trim to simplify

maintenance.

2. Record the nameplate information to req ui si-

tion spare parts for the regulator. The in for-

ma tion should include: Size, Product Code,

and Serial Number.

3. Refer to Section IX for recommended spare

parts. Only use original equipment parts sup-

plied by Cashco/KM for re build ing or re pair ing

regulators.

4. Owner should refer to owner's procedures for

removal, handling, cleaning and disposal of

nonreuseable parts, i.e. seals, etc.

5. The Inner Trim is re moved and replaced in the

body (23) as an assemblage of parts. The

Inner Trim Assembly, here in af ter called ITA,

consists of the fol low ing parts:

SECTION VII

Item Dynamic

No.

Seal Type

Part Description

13

..................... All

..........................Piston-Guide

Bearing

15 ..................... All ................................ Cage O-ring Seal

16.....................

UC.................................................Shim

19

..................... All

................................................... Cage

20

..................... All

...........................................Valve

Plug

21

..................... All

............................................ Seat

Ring

27 ..................... All ............................. Dynamic Side Seal

27.1 .............. CP............................................. Cap Seal

27.2 .............. CP..........................O-ring Energizer/Seal

27.3 .............. UC .......... U-Cup Seal w/Metal Energizer

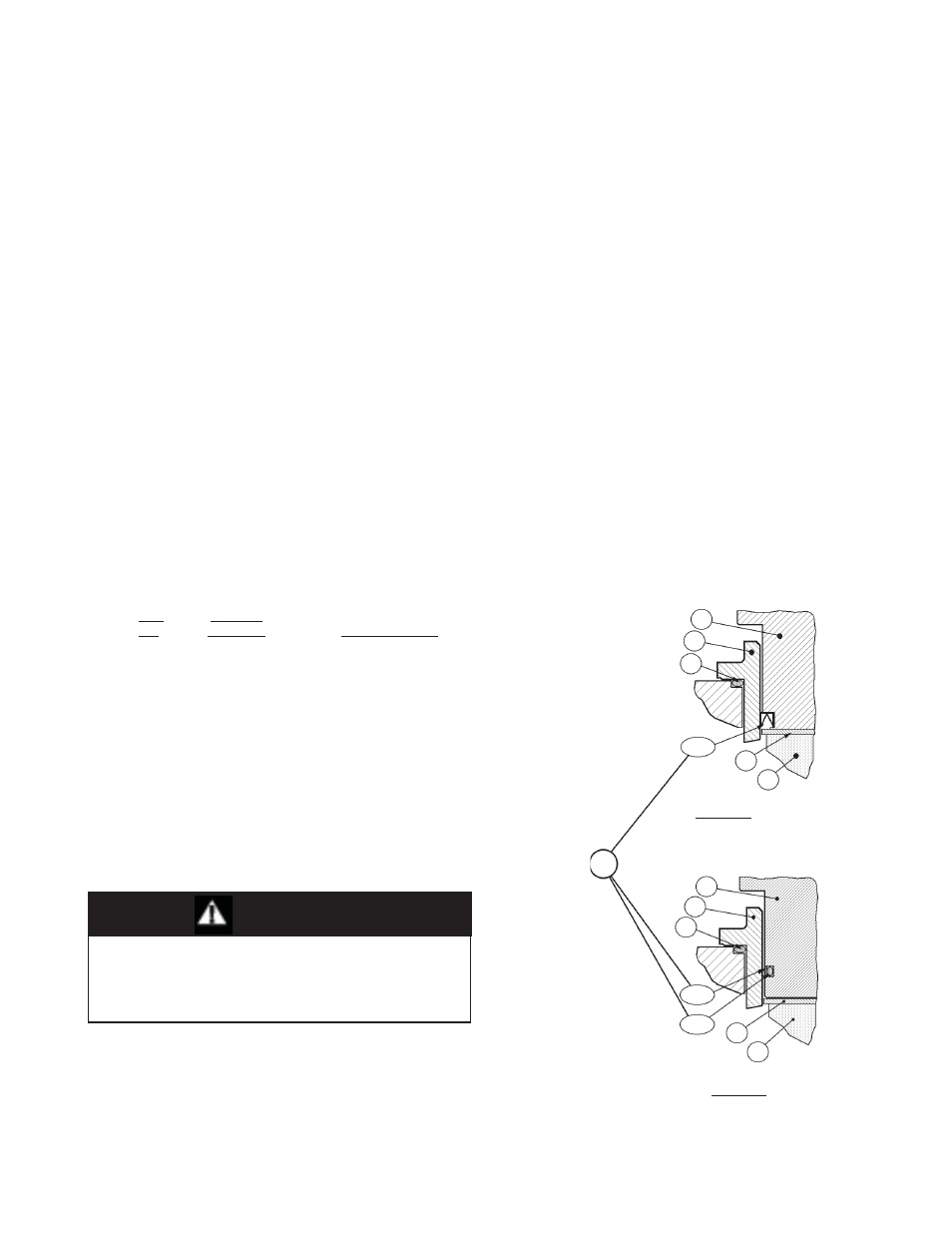

6. A detailed view of the dynamic side seal parts

is shown in Figure 1; an assembled ITA in

Figure 2; and a cross-sectional drawing of

the entire regulator is shown in Figure 3.

Figure 1: Dynamic Side Seals

ing screw (1) CCW (viewed from above) until

removed from spring cham ber (4).

3. Loosen

the

diaphragm

fl ange bolts (12) and

nuts (11) uniformly. Remove all bolting.

4. Place matchmarks on body (23) and spring

chamber (4) fl anges. Remove the spring

cham ber (4) by lifting vertically.

5. Remove the ball (14), spring follower (5) and

range spring (6).

6. Remove upper diaphragm pressure plate (8).

7. Remove diaphragm(s) (9) and examine to

de ter mine if failed. If diaphragms failed, de-

ter mine if op er at ing con di tions are ex ceed ing

designed pressure or tem per a ture limits.

8. Evenly loosen the three cage cap screws (18)

in single revolution increments. The reg u la tor

con tains a lower return spring (22); the ITA

should rise as the cage cap screws (18) are

backed out evenly. A downward holding force

should be ap plied to the top of the piston-guide

bearing (13) to pre vent the ITA from pop ping

up as the last threads of the cage cap screws

(18) are disengaged. Remove washers (17).

Type UC - U-Cup

Dynamic Seal

Type CP - Cap

Dynamic Seal

27

13

13

19

19

20

20

27.3

27.1

27.2

15

15

*

*

*

*

*

*

16

16

WARNING

SYSTEM UNDER PRESSURE. Prior to per form ing

any maintenance, isolate the reg u la tor from the

sys tem and relieve all pressure. Failure to do so

could result in personal injury.

B. Main Regulator Disassembly:

1. Shut down the system in accordance with

Section VI.

2. Loosen adjusting screw lock nut (2) and relax

range spring (6) pressure by turning ad just-