Cashco 5381 User Manual

Page 3

IOM-5381

3

VI. MAINTENANCE

SYSTEM UN DER PRES SURE. Prior to performing

any maintenance, isolate the reg u la tor from the sys-

tem and relieve all pres sure. Failure to do so could

result in personal injury.

To prevent damage to body, use lead jaws when

clamping body in a vise. Position body so that

vise does not close over inlet and outlet connec-

tions.

1. Securely install the body (1) in a vise with

the spring chamber (2) oriented up wards.

A. General:

1. Maintenance procedures here in af ter are

based upon removal of the reg u la tor unit

from the pipeline where installed.

2. Owner should refer to owner's pro ce -

dures for re mov al, handling, cleaning

and disposal of non reuseable parts, i.e.

gas kets, etc.

3. Refer to Figure 2 for basic regulator, item

number reference ( ).

B. Diaphragm Replacement:

SPRING UNDER COMPRESSION. Prior to re mov-

ing spring chamber, relieve spring com pres sion by

back ing out the adjusting knob. Failure to so so

may result in fl ying parts that could cause personal

injury.

2. Relax range spring (17) by turning adjust-

ing knob (30) CCW until re moved from

spring cham ber (2).

3. Loosen spring chamber (2) by placing

wrench on “fl ats” and rotating CCW mak-

ing sure not to use the fl at where the vent

hole is located.

4. Remove spring chamber (2), range spring

(17) and spring button (5).

11. For metal diaphragm(s) (13), place

dia phragm gas ket (14) into body re cess

(none re quired for com po si tion di a-

phragm). Set di a phragm sub as sem bly

into the body.

Sizes Diaphragm

Torque

Value

ALL

Metal

60 in/lbs. (6.8 Nm)

Composition

15 in/lbs. (1.7 Nm)

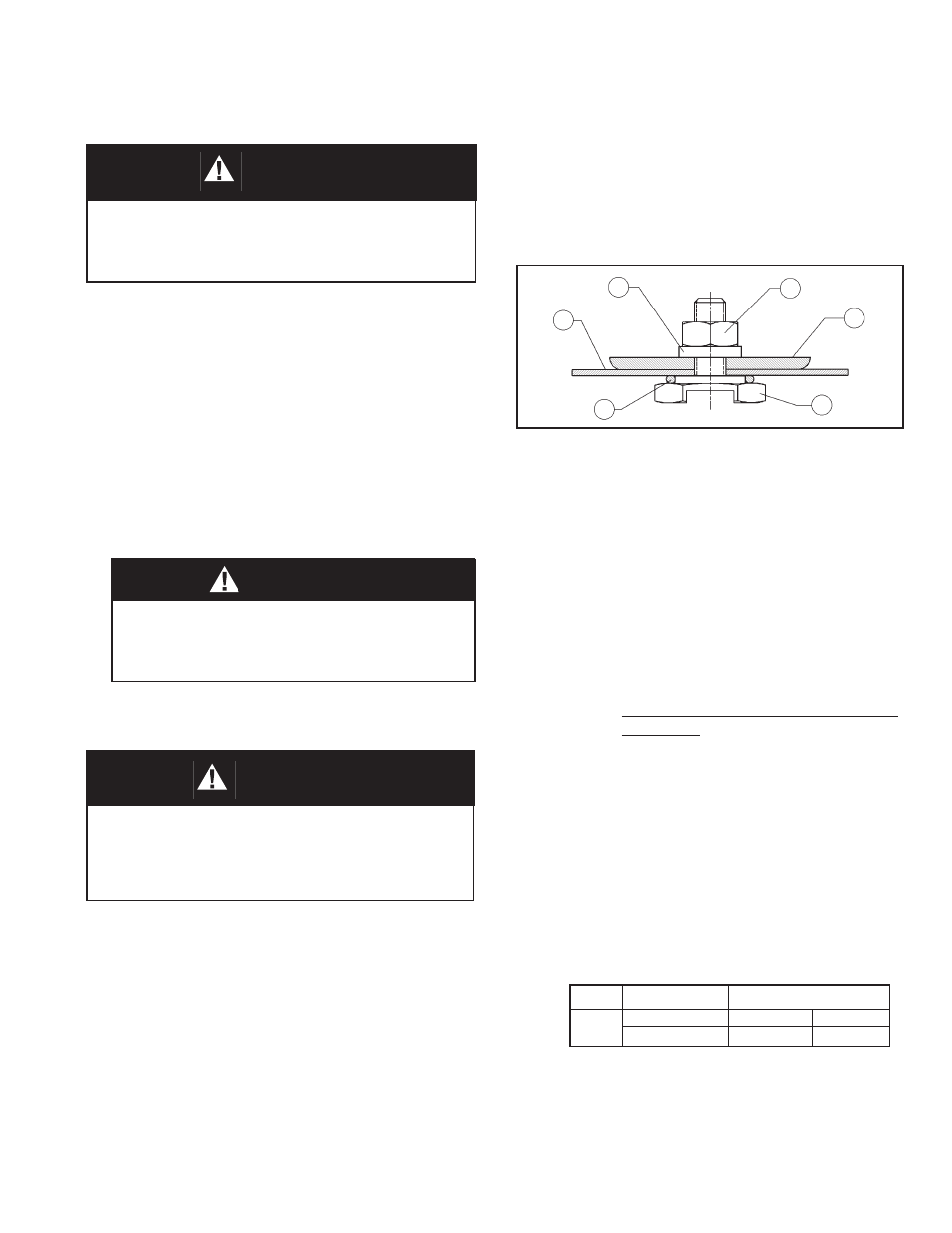

6. Loosen pressure plate nut (10) and

sep a rate all parts (3, 4, 9, 13 & 15) of the

diaphragm sub as sem bly.

7. Inspect pressure plate (3) to assure no

de for ma tion due to over-pressurization.

If de formed, re place.

8. Remove di

a phragm gasket (14). (If a

composition di a phragm is used there is

no di a phragm gasket (14).

9. Clean inside body surfaces in ac cor-

dance with Owner's cleaning pro ce dures.

Do not scratch di a phragm O-ring seat-

ing surface NOTE: Maintenance must

in clude a level of clean li ness equal to

Cash co clean ing stan dard #S-1576.

Con tact fac to ry for details.

10. Reassemble diaphragm subassembly

by plac ing push er plate O-ring (15),

diaphragm(s) (13), pressure plate (3) and

lock washer (9) over the threaded post

of pusher plate (4). As sure the pres sure

plate (3) is placed with curved outer rim

down next to the di a phragm (13) surface.

Tighten pusher plate nut (4) to the fol low -

ing torque values:

5. Remove the diaphragm subassembly

con sist ing of the pressure plate nut

(10), lock wash er (9), pres sure plate (3),

di a phragm (13), push er plate O-ring (15)

and pusher plate (4). NOTE: Refer to the

quan tity of dia phragms (13) in cor po rated

per the bill of ma te ri als listing. De pend ing

on outlet pres sure level, multiple metal

diaph ragms may be “stacked”.

Figure 1: Diaphragm Sub as sem bly

SECTION VI

WARNING

CAUTION

WARNING

13

9

10

3

15

4