Cashco DAP User Manual

Page 2

IOM-DAP

2

d. For condensable vapors (i.e. steam) slope the

external sensing line downward 2 to 5 de grees

to outlet piping to prevent water pock ets, which

allows the diaphragm chamber to always be

self draining. The external sensing line may

be sloped upward for liquids or gases.

5. The

loading

fl uid MUST be the same basic

fl uid as the fl uid passing thru the regulator

body.

1. When a loading pressure – P

Load

– is applied to

the top side of the piston (77), the outlet con trolled

pressure – P2 – will balance at ap prox i mate ly

0.96–.98 of the loading pressure - P

L

. (NOTE:

Fluctuations in P1 – Inlet Pressure will cause a

deviation in P2 – Outlet Pressure due to inverse

sympathetic ratio effect.) See Section VIII.

2. Movement occurs as pressure variations register

on the underneath side of the piston (77). The reg-

is ter ing pres sure is the outlet, P2, or down stream

V. STARTUP

1 Start with the block valves closed.

2. Adjust the loading system pressure control device

so that the main valve is trying to be controlled at

0 psig pressure.

3. If it is a “hot” piping system, and equipped with

a bypass valve, slowly open the bypass valve

to preheat the system piping and to allow slow

ex pan sion of the piping. Ensure proper steam

trap operation if installed. Closely monitor outlet

(down stream) pressure via gauge to ensure not

over-pressurizing. NOTE: If no bypass valve is

in stalled, extra caution should be used in starting

up a cold system; i.e., do everything slowly.

4. Crack open the outlet (downstream) block valve

to approximately 10% full open.

5. Slowly open the inlet (upstream) block valve to

about 25% open. Adjust the loading system pres-

sure control device setpoint pressure upwards

until the regulator is fl owing. Observe the outlet

pressure gauge to ensure not overpressurizing.

6. Continue to slowly open the inlet (upstream) block

valve until fully open.

7. Continue to slowly open the outlet (downstream)

block valve, especially when the downstream pip-

ing system isn’t pressurized. If the outlet (down-

stream) pressure exceeds the desired pres sure,

close the inlet block valve and go to Step 2. Close

bypass valve approximately 25%, and re peat pro-

ce dure.

8. When

fl ow is established steady enough that the

outlet (downstream) block valve is fully open, begin

to slowly close the bypass valve if installed.

pres sure. The loading pressure fl uid op pos es

piston movement. As out let pres sure drops, the

loading pressure push es the piston down, opening

the port; as out let pres sure in creas es, the piston

pushes up and the port opening closes.

3. A complete piston dynamic seal failure will cause

the reg u la tor to fail closed. A loss of loading pres-

sure while inlet pressure is im posed will cause

valve to fail closed.

SECTION IV

IV. PRINCIPLE OF OPERATION

SECTION V

CAUTION

DO NOT HYDROSTATIC TEST THROUGH AN IN STALLED

UNIT; ISOLATE REGULATOR FROM TEST. The pressure

level on the name plate is the rec om mend ed “upper op er -

at ing limit”. High er pres sures could cause in ter nal dam age.

In ad di tion, note on the name plate that the Inlet and Outlet

pres sure and tem per a ture ratings are at different levels.

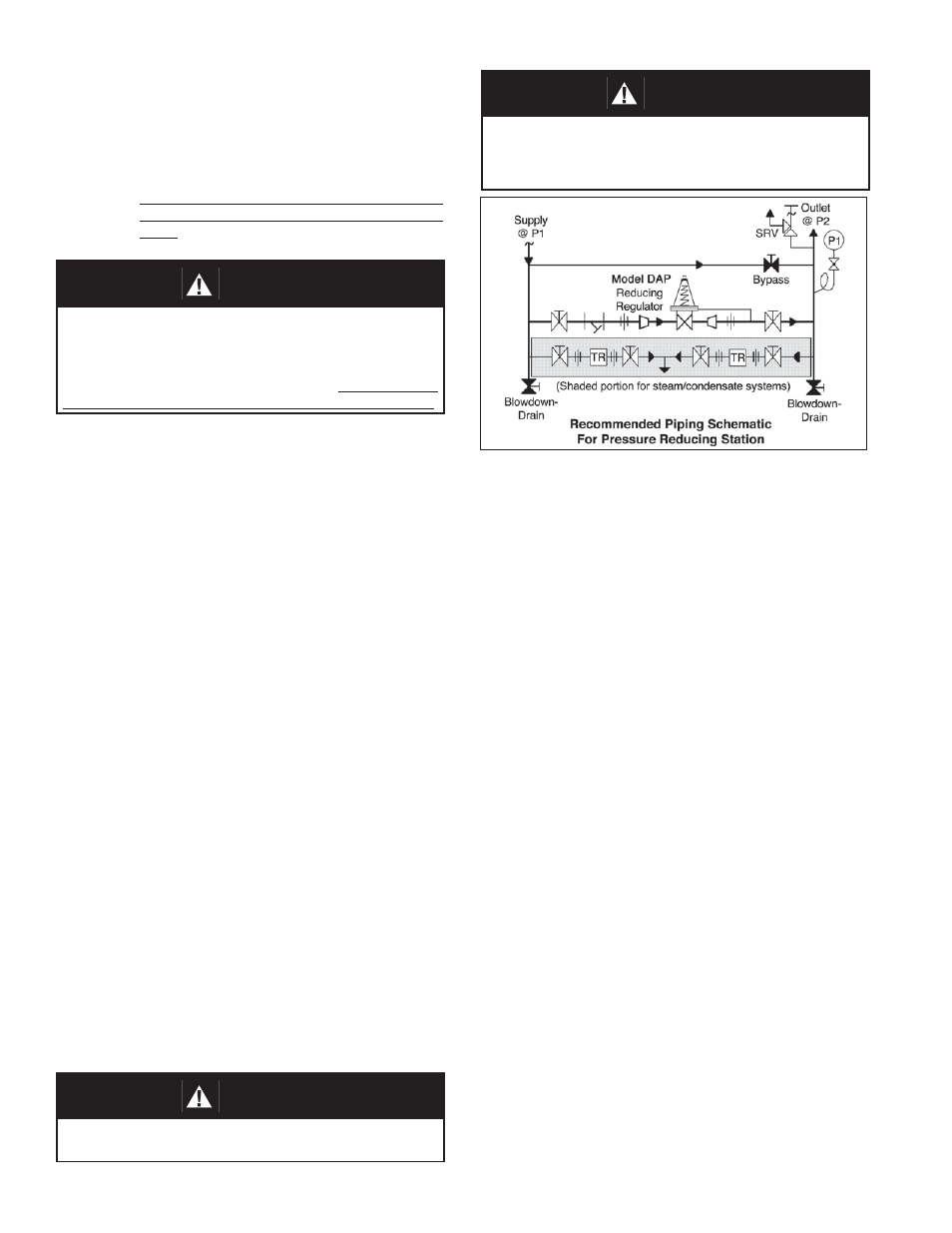

CAUTION

Installation of adequate overpressure pro tec tion is recom-

mended to pro tect the reg u la tor from over pres sure and

all down stream equip ment from dam age in the event of

regulator failure.

CAUTION

Do not walk away and leave a bypassed reg u la tor unat-

tended!