Ignition primary - distributor – GxT V055-01 Diagnostic Analyzer User Manual

Page 9

9

IGNITION ENERGY

Ignition energy is the quality of the ignition coil inductance.

This indicates the coil “kick” in milliVoltSeconds (mVSec).

The engine must be cranking or running to produce a

readable signal. Typical standard ignition coils produce

25 to 40 mVSec. High energy ignitions have 40 to 60

mVSec. Readings below 20 mVS suggest that inadequate ignition energy is being delivered by the coil.

COIL OSCILLATIONS

This is an indicator of liveliness in the ignition coil. Shorts in coil insulation or in connected components

usually dampen the oscillations so they are reduced or eliminated. Points driven ignition coils usually

show 4 to 8 oscillations, which are more than electronic ignitions that do 1 to 4. Some Chrysler ignition

modules begin dwell immediately after the spark burn, so they normally do not show any oscillations.

DRIVER MODULE / POINTS VOLTAGE

“Driver” is the voltage during the dwell time. For mechanical points it should be less than 0.3 volts.

Electronic modules typically have 0.5 to 1.5 volts. Ignitions made alike should compare within 0.2 volts.

In this test, a higher voltage indicates a failing (high resistance) coil driver output transistor, bad points,

or a high resistance connection to ground.

DWELL

Press SELECT to display dwell in degrees, percent, or milliSeconds. MilliSeconds are useful for checking

the charging time for current-limited electronic ignitions, which take a fixed time to build up the coil amps.

A typical HEI coil charges in 3.5 mS at idle RPM, and 4.5 mS while cranking.

DWELL VARIATION

This is the difference in degrees between the longest and shortest dwell period. On electronic ignitions, it

could be from an unstable coil drive module. On points ignitions, mechanical sloppiness in the distributor

shaft bearings and cam shaft drive is the prime cause. At higher speeds, on points ignitions, the problem can

be floating contacts due to weak springs and poor lubrication. Readings should be less than 3 degrees.

TIMING VARIATION

Variations in timing is the difference in engine shaft degrees of the longest and the shortest times between

ignition firings. On pre-computer engines, variation meant looseness in the mechanical drive from the

crankshaft to the points cam. Sometimes timing is intentionally varied by engine computers.

Irregular idle RPM from O2 feedback fuel metering can cause timing variation also. Operating the engine at

higher RPM should reduce the variation to under 3 degrees. Read variation from 1000 to 3000 RPM with the

RPM held steady. During acceleration or deceleration, the Timing Variation is not a valid measurement.

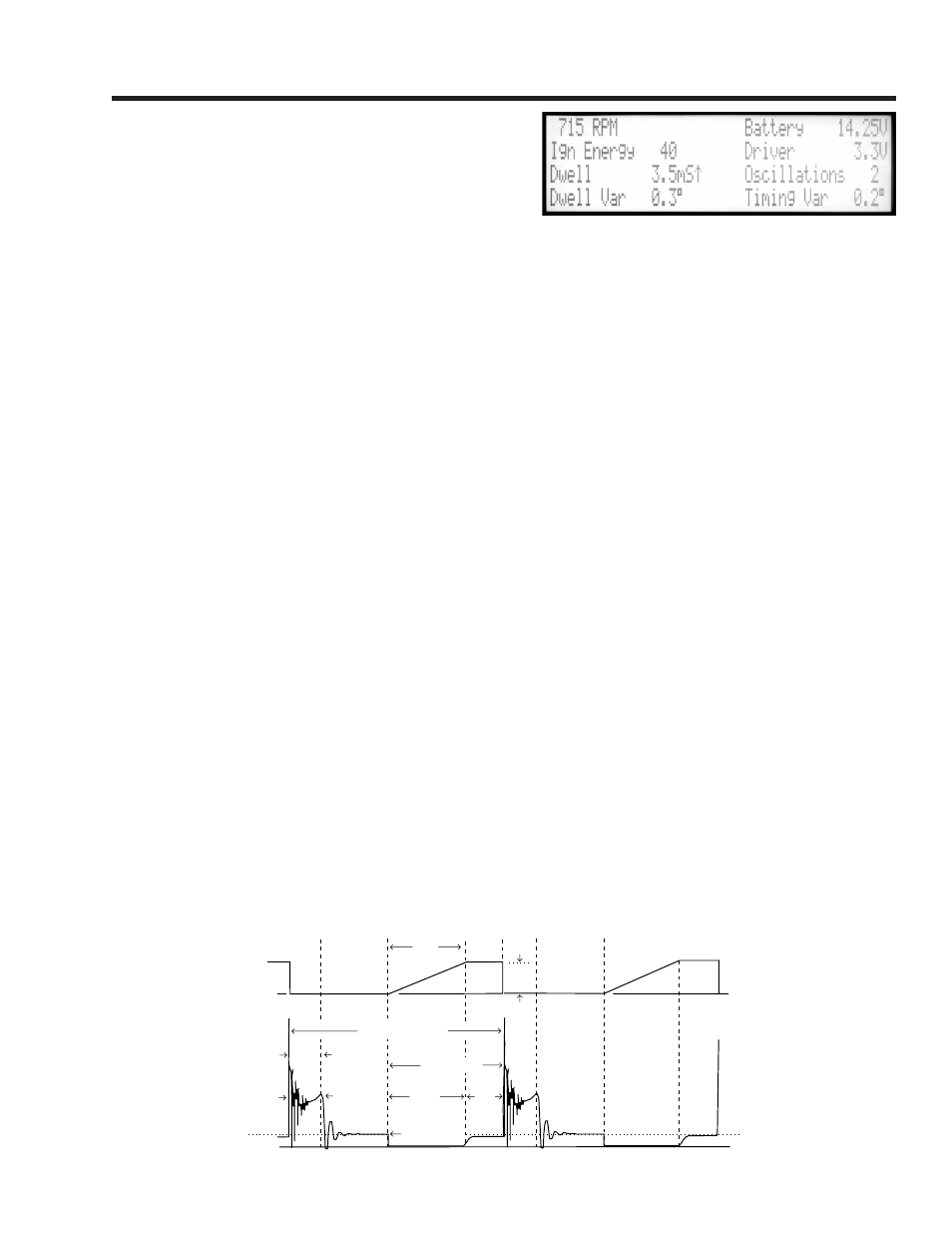

Ignition Primary - Distributor

PRIMARY

AMPS

BUILD

mSec

COIL

PEAK

AMPS

SPARK

LINE

PRIMARY

VOLTS

0 v

SPARK

BURN

TIME

IGNITION TIMING CYCLE

BUILD

(DWELL)

AMPS

HOLD

DWELL SECTION

BATTERY

VOLTAGE

Ignition Coil Primary Current and Voltage