GxT V055-01 Diagnostic Analyzer User Manual

Page 12

12

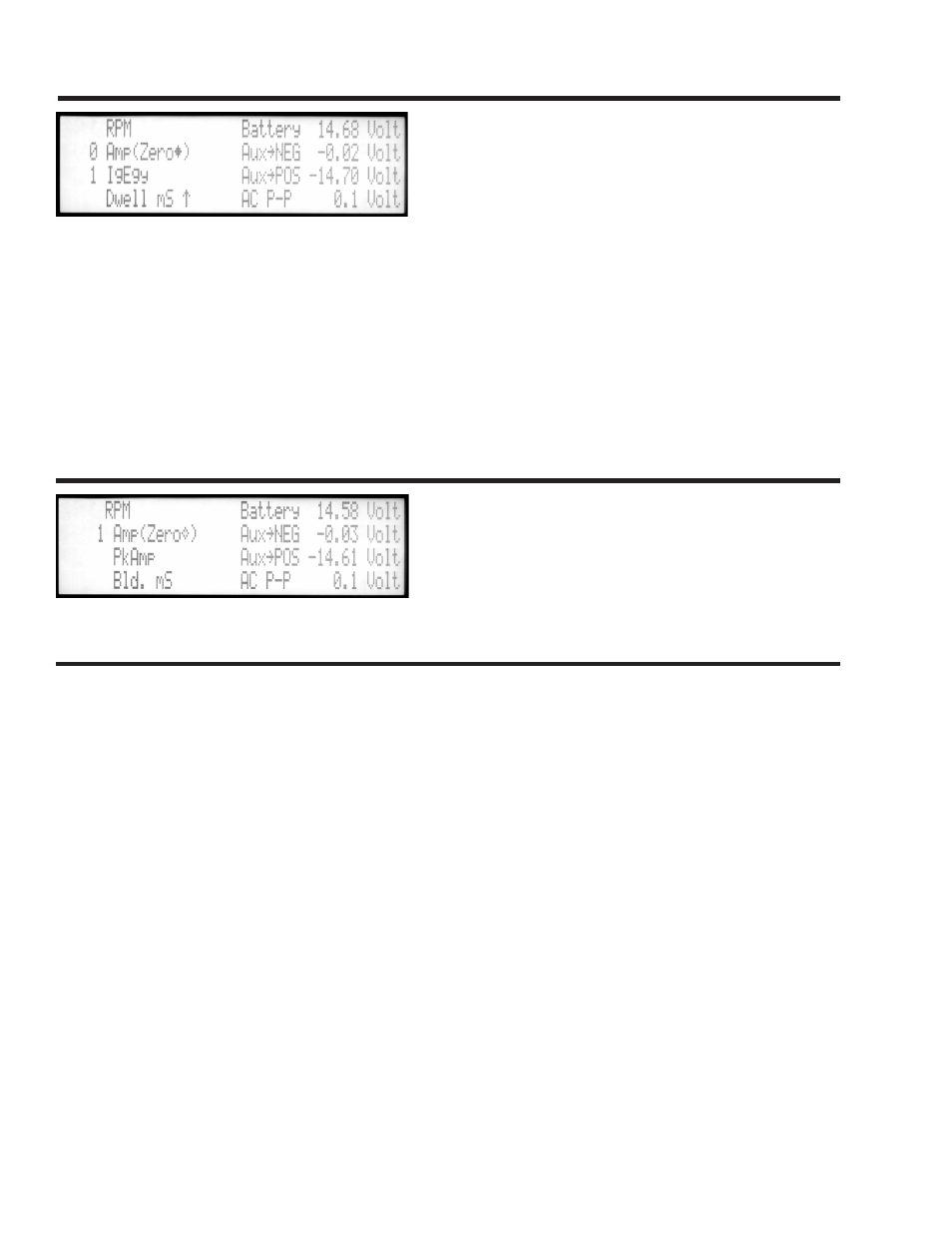

Use this test to find the problem area on a no-start

engine. If a Distributor ignition was selected during

Engine Setup, this screen will appear.

The ignition signal for this test comes from the Coil

Primary Clip connected to the Coil (-), TACH terminal

of the coil.

The Amps reading shows starter draw, measured by the Inductive Amp Probe. The probe should be zeroed

before testing. To zero, press NEXT and follow the on-screen instructions. Ignition Energy shows the coil's

charge level. Dwell shows coil charging time. Auxiliary Volts can be measured, using the Auxiliary Meter

Lead, to confirm that voltage is present at the ignition or to detect voltage drops in cables and connections.

Voltage at the lead, referenced to both the positive and negative battery power clips, is shown. Volts AC

P-P (peak-to-peak) can be used to check the output of pulsing type sensors. RPM and Battery Voltage

are used to measure the performance of the cranking system. Special diagnostics pick out problems with

the spark plugs, wires, cap and rotor.

This screen is similar to the one for Distributor ignitions,

but Peak Amps and Build Time are measured instead of

Ignition Energy and Dwell.

This procedure will be helpful when diagnosing DIS no start cars. Do not skip any steps, and do not

perform this test until you are experienced in using the EngineLink LT. Improper connections can lead to

an incorrect diagnosis.

1. Select the IGNITION:PRIMARY test, then try to start the engine. The following readings should be

within the stated guidelines:

Battery Volts:

Should be greater than 9.6 volts. If not, diagnose and repair the starting/charging

system.

RPM:

Should be appropriate for the engine being tested.

Peak Amps:

Refer to the Typical readings section of this manual, Page 25. This will diagnose the

module, and coils. If you do not read any peak amps, check to see there is 12 volts going

to the module. If 12 volts are present, use a labscope to check the Cam/Crank Sensor.

If the sensors are good, the module is defective. If all of the above readings are good,

the coils, modules, crank and cam sensors are operating properly.

2. Check fuel pressure and volume. If the results are good, proceed to the next step.

3. Use the Fuel Injector Test on the EngineLink LT. During cranking the Peak Amps reading should

not be greater than 4 amps. If Peak Amps are greater than 4, you have located a defective injector.

Wiring diagrams for the fuel injection system on the car you are testing are an invaluable tool when

Hard Start - Distributor

Hard Start - DIS & No Coil Minus (-)

Troubleshooting DIS No-Start Cars