Power balance - automatic/manual – GxT V055-01 Diagnostic Analyzer User Manual

Page 15

15

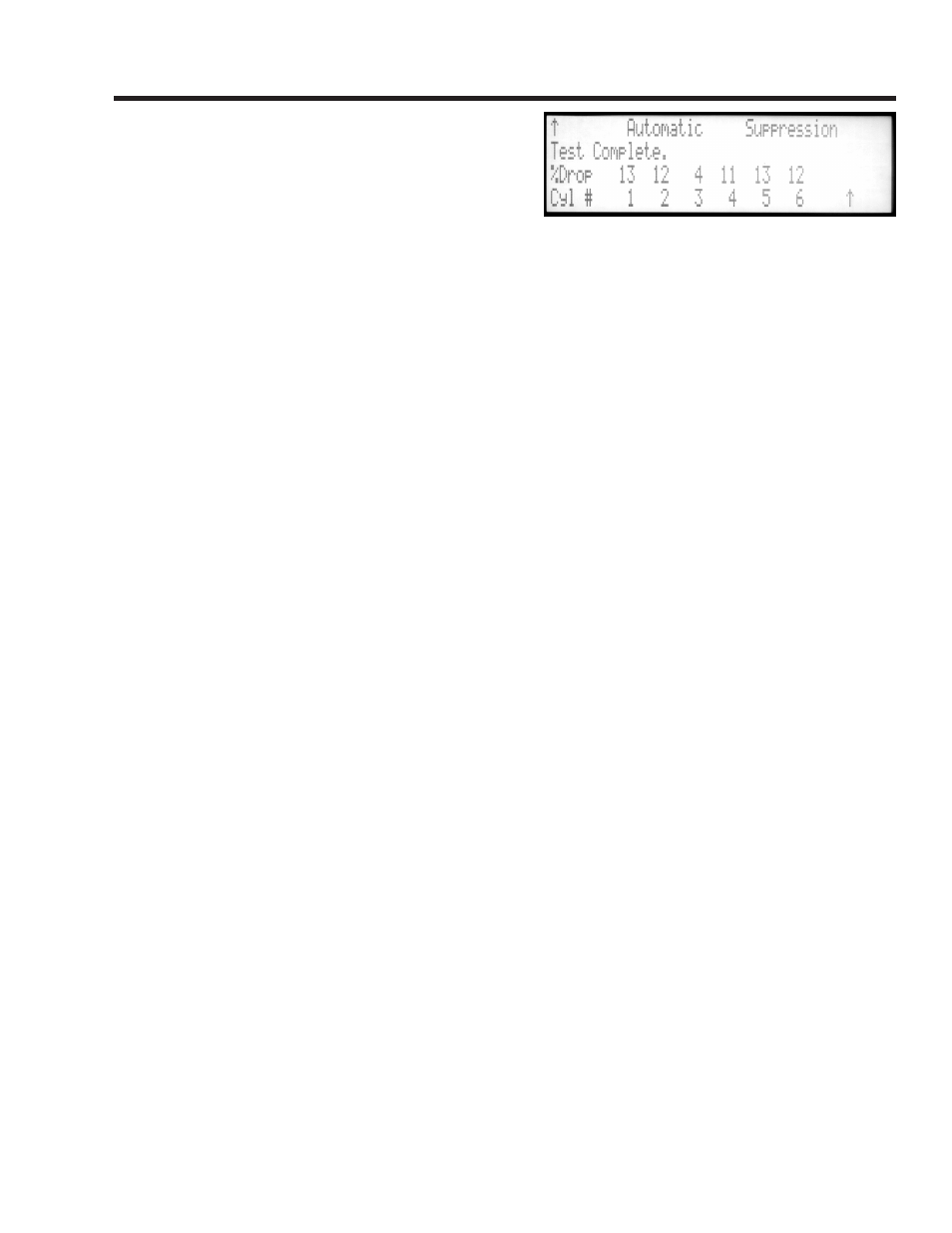

Power Balance - Automatic/Manual

On distributor engines, power balance, or each cylinder’s

power contribution relative to the others, can be seen by

turning off the spark plugs one at a time and measuring

the drop in RPM. In Automatic mode, the Diagnostic

Center will suppress ignition to each cylinder in turn, and

will display and save the starting and ending RPM for

each. The more RPM decrease seen, the more a cylinder

must have been contributing. If all cylinders are contributing equally, RPM drops will be consistent among

cylinders. If a cylinder shows only 1/3 of the drop of the average cylinder, it should be checked further

with the other EngineLink tests. If all drops are very low, see the facing page for advice on defeating idle

compensators which may be raising idle speed in response to the suppression.

The test relies upon steady timing, fixed air-fuel feed and a constant amount of engine drag during the

test to make valid comparisons between all of the cylinders. If the RPM drifts during the test, a message

will appear, indicating the test should be run again.

A steady drag on the engine can improve the test results. Turning the heater fan on high and headlights

on bright is usually the best method. Particular attention should be directed to eliminating loads that can

turn on or off in the middle of the test such as the air conditioner compressor and radiator fan motor.

Operating the engine above the controlled idle RPM will minimize the effects of idle compensators and

put the engine at a smoother operating point. RPMs of 1000 to 2500 are suitable for the test. Listen to

the sound of the engine as suppression is applied. A large initial RPM drop is a good indicator of a strong

cylinder.

On non-computerized engines the timing, fuel mix and idle setting do not vary with time. However, active

control systems may have to be put in open-loop mode to keep the timing and fuel mixture fixed, so that

the test results do not end with minimal % Drops.

After the test, carefully restore the disengaged parts. Service codes may be set during the test, but they

will usually clear automatically after 50 to 100 starts.

Low power cylinder problems are associated with spark plugs and wires, piston rings, valves and valve

springs, vacuum leaks, fuel unbalance, head gaskets, and EGR problems. If a cylinder test produces a

higher RPM it may be from crossed spark plug wires, an open intake valve, leaking EGR, or an engine

computer effect.

The results of this test, if compared to the Electronic Compression and Ignition Secondary tests, can

provide additional clues about the cause of poor cylinder performance.

Manual Mode

Manual suppression can be used to listen for noise changes in an individual cylinder that may give clues

about the problem.

To suppress ignition in an individual cylinder, choose Manual Suppression from the POWER menu and

SELECT the cylinder you want to suppress. Press NEXT to suppress ignition to that cylinder.