Zero based calibration, Delta "r" table – Fluid Components International MT86_MT86HT Manual Operation User Manual

Page 3

Doc. No. 003162 Rev. F

3 - 3

Models MT86, MT86HT

CHAPTER 3 - OPERATION

FLUID COMPONENTS INTL

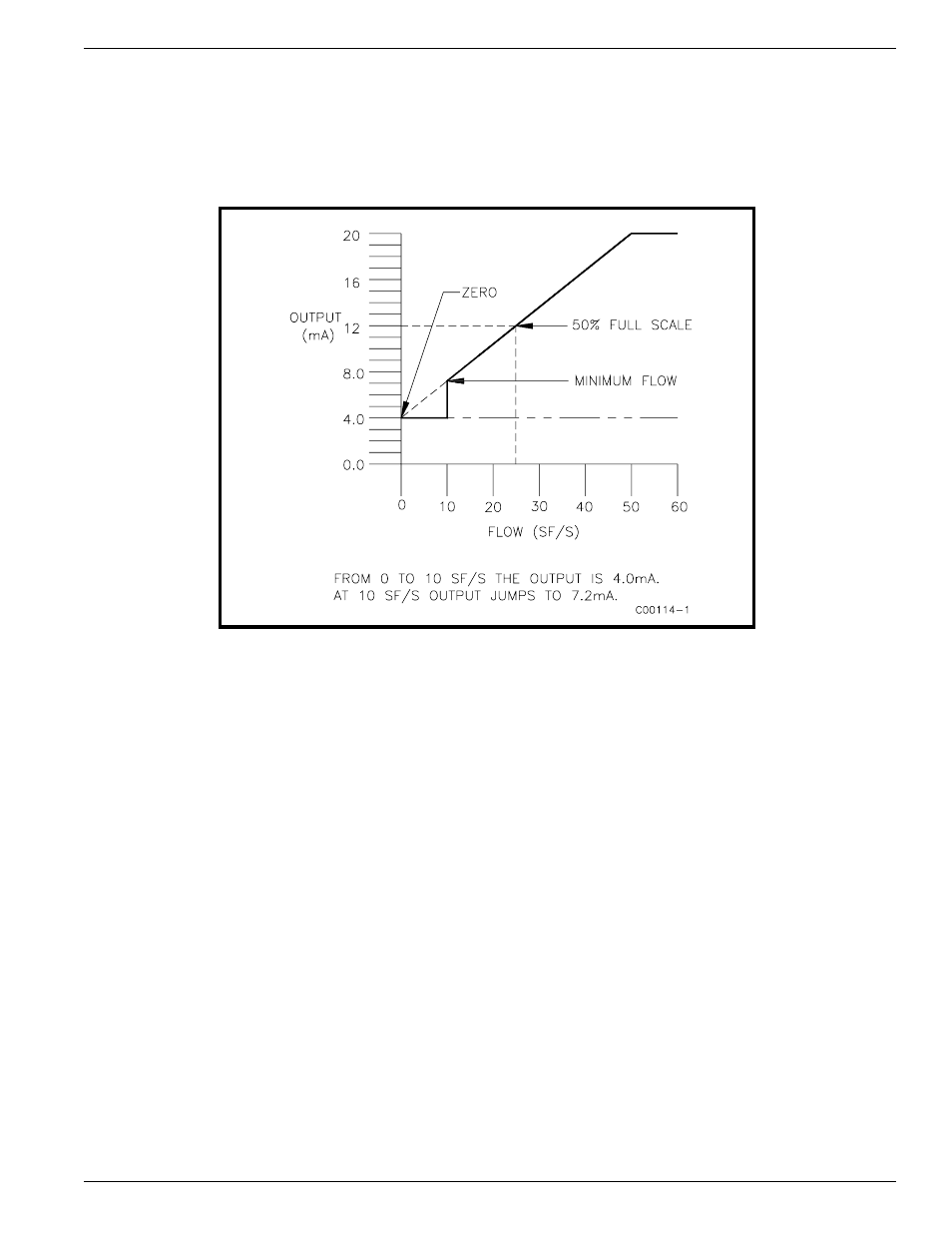

Zero Based Calibration

In a zero based calibration, the slope of the output signal is shifted so the low-limit flow output signal (4 mA) is

equal to zero flow. See Figure 3-2 for details. Flowmeters cannot measure zero flow accurately. The flowmeter will

readout the low-limit signal (4 mA) from zero flow up to the minimum calibrated flow. Then the output signal will

step up to the proper signal value of the mass flow.

The output signal is easier to interpolate when milliamp output is interfaced with control room 0 to 100% gauges;

50% of the signal will correspond to 50% of the maximum flow rate.

Zero based flowmeters have less signal to resolve over full scale. A zero based flowmeter with a turndown ratio of

10:1 will have 10% less output range to resolve flow (5.6 mA to 20 mA instead of 4 mA to 20 mA in a non-zero

based flowmeter).

Delta "R" Table

The actual data chart for this particular flowmeter can be found in the page protector at the back of this manual. The

Delta "R" part of this sheet gives the factory calibration measurement points of the Delta "R" differences between the

REF and ACT RTDs at certain flow rates. These measurements used by the factory determine the linearization

coefficients that are applied over the desired flow range. The corresponding current and voltage output readings are

also shown for the factory default settings.

The flow versus Delta "R" relationship is fixed for a given set of sensing points. There is a lookup table that is in the

page protector in the back of this manual. It is a printout of factory default settings for zero and offset readings. The

table shows the relationship between the displayed mass flow readings as they are related to the current output. The

output is calculated over the entire flow range with the use of a fitting equation and its respective coefficients.

The Delta "R" Table has a great deal of useful information. The table can be used to verify the correct operation of

the flow transmitter without the flow elements connected. By using the Delta "R" Table the flow element sensing

points are simulated with precision resistors or decade boxes.

Figure 3-2. Zero Based Calibration