Alarm adjustment procedure – Fluid Components International FLT93 User Manual

Page 5

FLT93 Flow Switch Series

FLUID COMPONENTS INTERNATIONAL LLC

Doc. No. 06EN003312 Rev. D

5

This page is subject to proprietary rights statement on last page

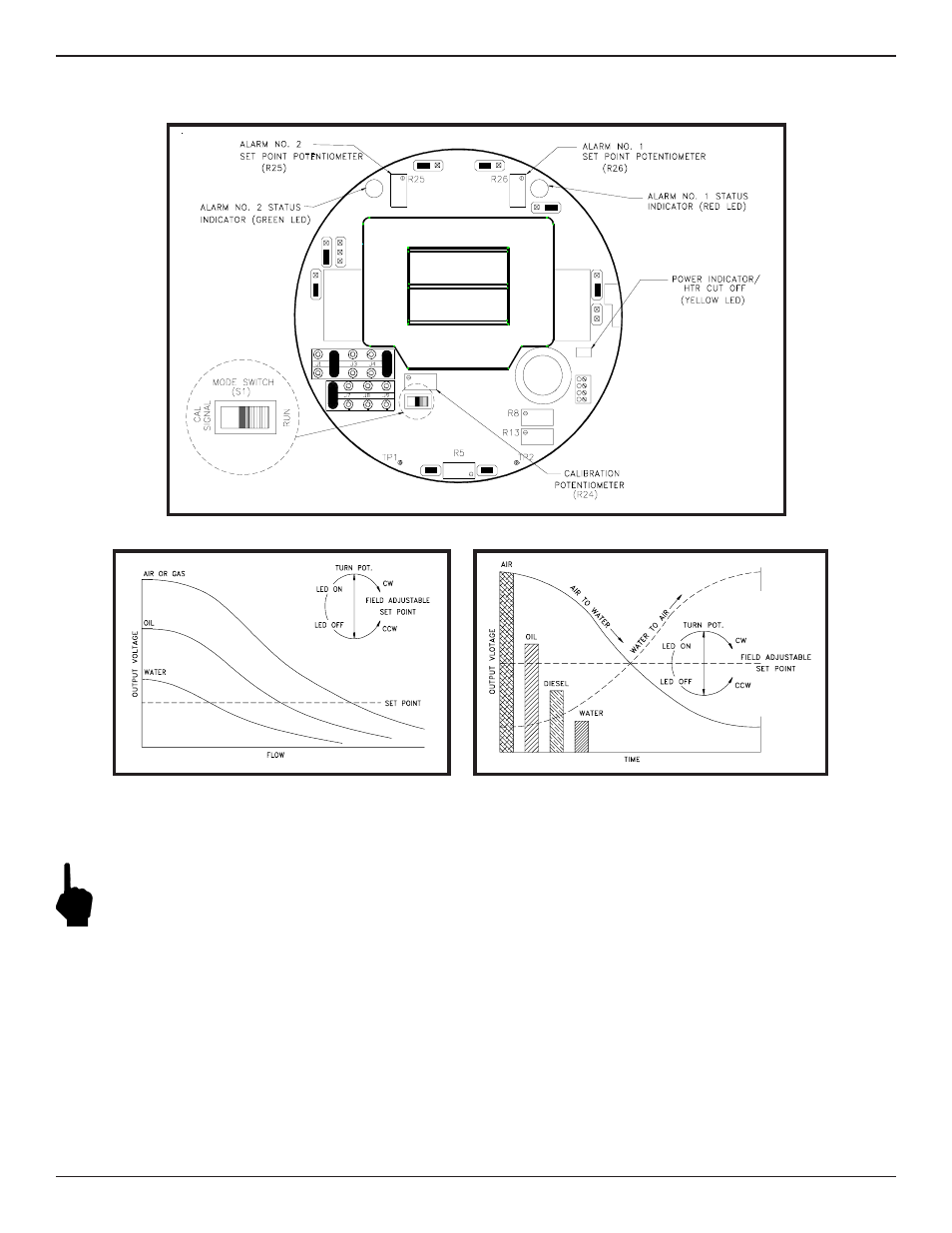

Alarm Adjustment Procedure

(Not necessary if the instrument has been factory calibrated.)

Control Circuit Adjustment Locations

Flow Application Signal Output

Level Application Signal Output

Adjustment by Observation (Option 1)

Note: The control circuit has two mutually exclusive alarms; they are identified as Alarm No. 1 and Alarm No. 2 and

each has a set point adjustment potentiometer and LED indicator. Each alarm can be setup for one of three

applications: flow, level/interface, or temperature. The following application specific adjustment procedures

are generic and can be used for setting either or both alarms. The mode switch must be in the RUN position.

Use the top figure on this page to help locate the adjustment potentiometers and LEDs.

Flow Applications

1. Ensure that the instrument has been properly installed in the pipeline. Fill the pipeline so the sensing element is

surrounded by the process media.

2. Apply power to the instrument and allow fifteen minutes for the sensing element to become active and stabilize.

3. Flow the pipeline at the normal or expected rate. Remove the enclosure cover to allow access to the control circuit

to make adjustments.