Troubleshooting – Fluid Components International FLT93 User Manual

Page 11

FLT93 Flow Switch Series

FLUID COMPONENTS INTERNATIONAL LLC

Doc. No. 06EN003312 Rev. D

11

This page is subject to proprietary rights statement on last page

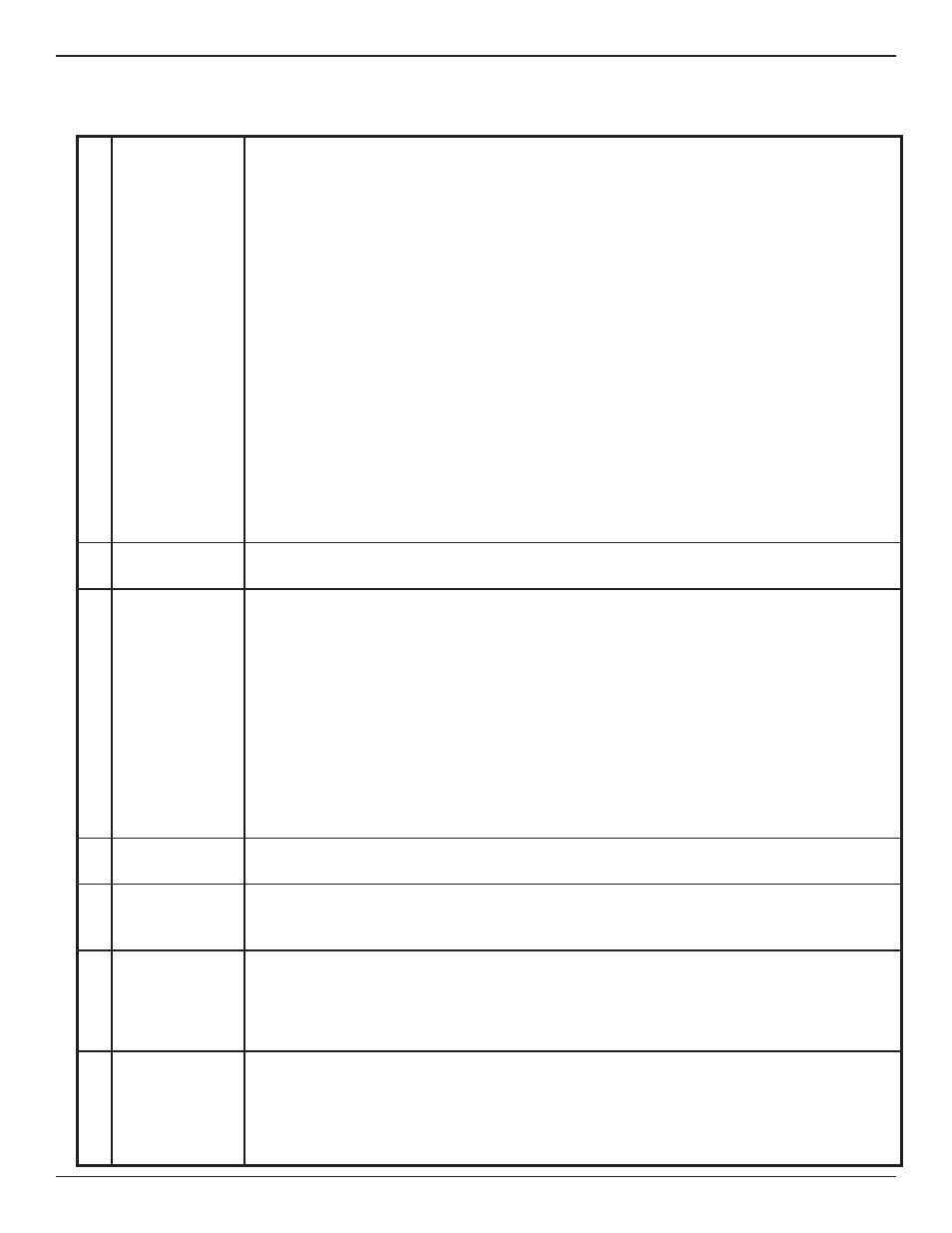

Troubleshooting

LED ON

Although the LED is on, it may appear dim. This is usually caused by the instrument being supplied

with 115 Vac and the Input Power Jumper Configuration set to 220 Vac.

Input power and jumper configuration:

OK: See item 2, Mode Switch.

NOT OK: Remove the control circuit and set the jumpers correctly. Reinstall the control circuit and

restart the system.

LED OFF

Check the Input Power Jumper Configuration setting and verify the input power.

OK: See item 4, Power Supply Check.

NOT OK: Remove the control circuit, set the jumpers correctly and verify the input power. Reinstall

the control circuit, restart the system and check for proper operation. If LED is still off go to Wiring the

Instrument, page 3.

LED BLINKING

For Liquid Flow Applications: Sensor is DRY. Make sure the pipe is full.

For Gas Flow Applications: Heater power set too high. Set to lower value by moving heater jumper.

For Liquid level Applications: Heater power set too high. Set to lower value by moving heater jumper.

For Liquid Interface Applications: Set the heater power to the maximum value to achieve the maximum

signal difference between the two liquids. For liquid applications, it is normal for the LED to blink if

the element goes dry. Go to item 2, Mode Switch.

1. Is the Yellow LED

on,off, blinking, or

dim?

2. Mode Switch

Make sure the mode switch is in the “RUN” position.

OK: See item 3, Signal Voltage Observation.

7. Alarm Switch Point

Settings

Remove the Heater Wattage Control jumper. Measure the signal voltage at P1, Terminals 1 and 2.

a) The voltage is 0 volts +/- 25 mV:

OK: Reinstall the jumper and wait 5 minutes. Go to c) or d) which ever is applicable.

b) The voltage is out of tolerance:

NOT OK: The serial numbers on the control board and the sensing element must match. If the

serial numbers are OK then contact FCI Field Service.

c) The Voltage is between 1 and 6 volts and changes with flow or level changes:

OK: See item 7, Alarm Switch Point Settings.

d) The voltage is still about 0 volts: or the voltage is over + 7 volts: or the voltage is negative,

between -1 and -6 volts and changes with flow or level changes:

Not OK: Sensing element not wired correctly or defective. Incorrect wiring on remote instruments

is not uncommon upon initial installation. For integral installations, see item 5 in this section or for

remote installations, see item 6 in this section.

Measure the voltage at P1 terminals 2 to 4.

Voltage is 0 volts: NOT OK; Contact FCI Technical Service. Replace with spare control board.

3. Signal Voltage

Observation

Turn off the power and remove the control circuit. Check sensing element connections.

Sensor Failure: Call the Factory

Sensors are OK: See item 7, Alarm Switch Point Settings.

Turn off the power and remove the control circuit. Check the flow element connections versus the

wiring diagram.

Remote cable incorrectly wired or damaged: Repair and restart the system.

Sensor Failure: Call the Factory

Sensors are OK: See item 7, Alarm Switch Point Settings.

Make sure that the jumpers are set correctly. The related settings are the "Alarm Duty", "Alarm

Quantity" and the "Energization". Refer to the previous tables or the bottom side of the control circuit

for more information.

Using the Mode Switch set to Cal, check and record the alarm settings. Compare these setting to the

signals generated by the process and make adjustments if necessary.

5. Sensor Element

Check for

Integral Installation

6. Sensor Element

Check for Remote

Installation

If you continue to experience problems with the instrument, see the Troubleshooting Section in the FLT93 Manual, document

number 06EN003246. To acquire a manual, call your local FCI Sales Representative.

4. Power Supply

Check