Installation safety instructions – Burkert Type S039 User Manual

Page 5

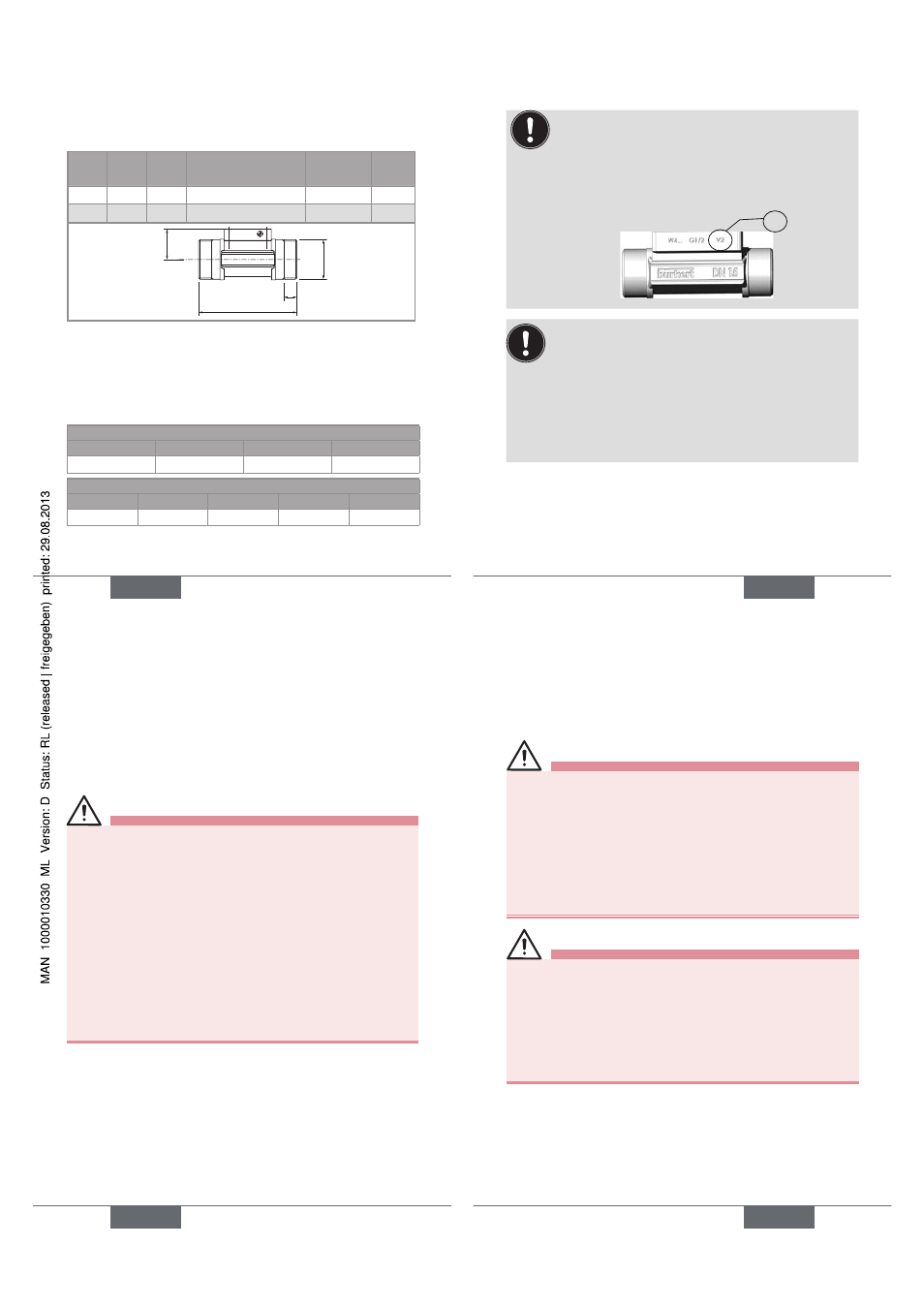

16

Table 2: Dimensions of the fittings with G, NPT or

metric external thread connections

DN

[mm]

P

[mm]

A

[mm]

D [inch]

[mm]

L

[mm]

06

29,7

90,0

G 1/4 or G 1/2

-

14,0

08

29,7

90,0

G 1/2 or NPT 1/2

M 16 x 1,5 14,0

A

L

D

P

K factors (pulse/litre)

The K factors have all been determined under the following

reference conditions: medium = water, water and ambient

temperatures 20 °C, min. upstream and downstream

distances respected, appropriate pipe dimensions.

K factors (pulse/litre)

DN06

DN08

DN15

DN15 v2

450

288

93,6

74,8

K factors (pulse/litre)

DN20

DN25

DN32

DN40

DN50

60,3

45,9

28,7

18,2

10,4

English

17

Two versions of the S039 in DN15 exist, having

different K factors.

Only version 2, identified by the "v2" marking, is

available from March 2012. The "v2" marking can

be found on the side of the DN15 fitting in metal:

V2

To convert a K factor given in pulse/litre, use one

of the following formulae:

K factor in pulse/US gallon = K factor in pulse/litre

x 3.785 to obtain a flow rate value in US gallon/

time unit

K factor in pulse/UK gallon = K factor in pulse/litre

x 4,546 to obtain a flow rate value in UK gallon/

time unit

English

17

18

7. inSTAllATion

Safety instructions

danger

risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut-off the pressure

and drain the pipe before loosening the process

connections.

risk of injury due to high fluid temperatures.

• Use safety gloves to handle the fitting.

• Stop the circulation of fluid and drain the pipe before

loosening the process connections.

risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident pre-

vention and safety relating to the use of hazardous

products.

English

19

Warning

risk of injury due to non-conforming installation.

• Fluidic installation can only be carried out by qualified

and authorised personnel with the appropriate tools.

• Observe the installation instructions for the measuring

device inserted into the fitting.

risk of injury due to an uncontrolled restart.

• Ensure that the restart of the installation is controlled

after any interventions on it.

Warning

risk of injury if the fluid pressure/ temperature

dependency is not respected.

• Take into account the fluid pressure/ temperature

dependency according to the materials from which the

fitting is made and to the measuring device used (see

the relevant user manual).

• Comply with the Pressure Directive 97/23/EC.

→

Select an appropriate fitting regarding to the flow

velocity and the flow rate of the fluid in the piping, see

the following charts:

English

19