Start-up – Burkert Type BBS-4S User Manual

Page 4

8

CAUTION:

Risk of injury from improper installation.

• Installation and construction of the device may be carried out by

trained personnel only and in consideration of the safety standards.

→

Pace half nuts (2) around the hose and clamp, using a press, if

required.

→

Tighten the screws (4) diagonally and evenly.

NOTE!

Leak due to incorrect installation

• Do not jam or tighten the hose nut halves unevenly. The gap

between the halves should not exceed 3.5 mm.

6.4. Disassembly

Disassembly is in reverse sequence to assembly.

6.5. Installation in pipeline

BBS-4S hose coupling without welded connection can be connected

to the pipeline by using connecting elements BBS-03, BBS-05,

BBS-06 and BBS-25.

The installation instructions can be found in the corresponding oper-

ating manual. They can be found on the Internet at www.burkert.com.

Please note the following bending specifications for silicone hoses:

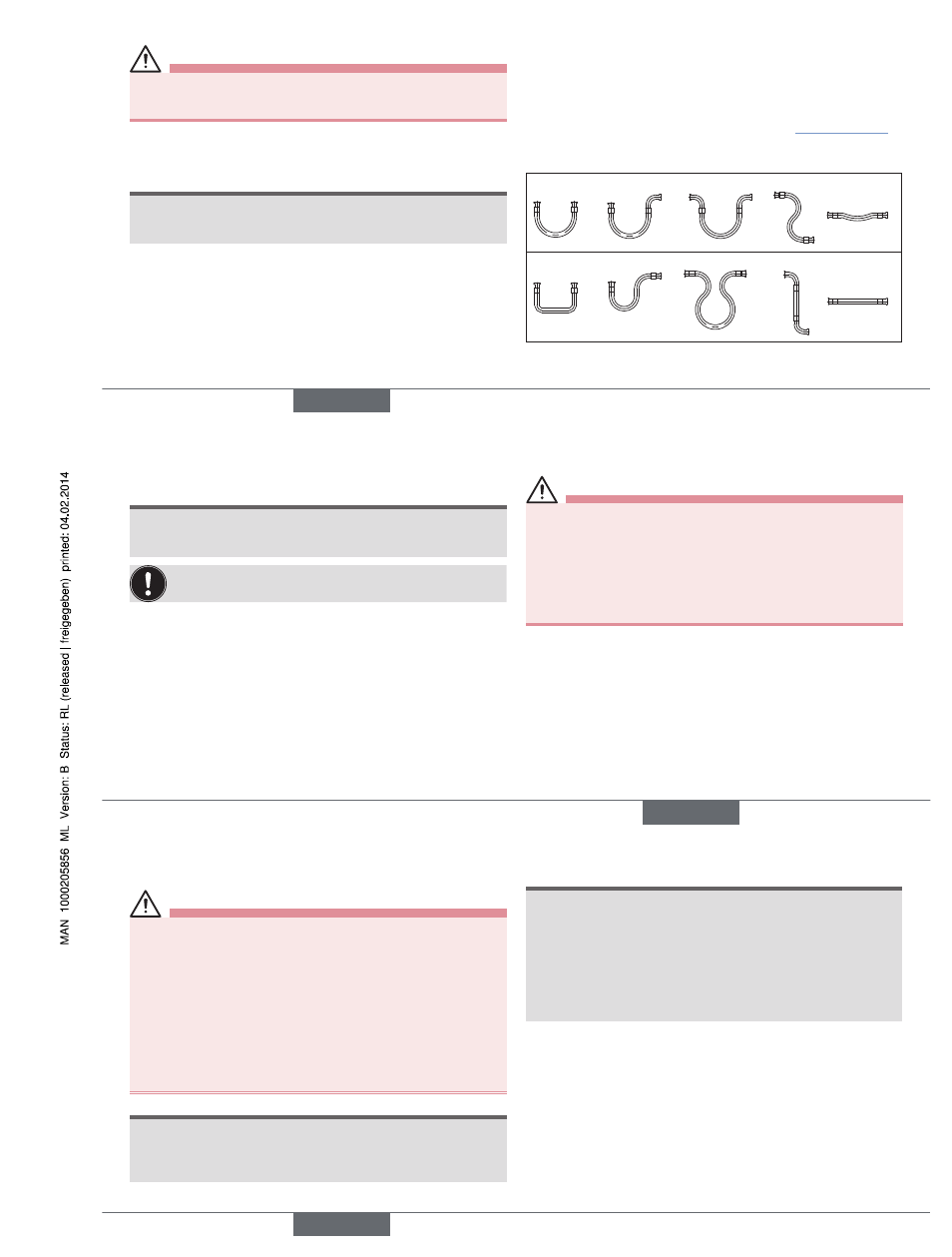

Installation permitted:

Installation not permitted:

Fig. 4:

Bending specifications for silicone hoses

english

9

6.6. Welding in of the hose

coupling with welded connection

NOTE!

Leak due to damaged O-rings or silicone hose.

• To ensure the sealing function, protect the O-rings and the silicone

hose during installation, welding and cleaning procedures.

Only adequately trained personnel may weld in and rework the

product.

→

Connect the parts positively in a protective gas shield.

When cleaning the weld seam by grinding or acid cleaning, observe

the following before assembling the connection:

• Carefully remove all grinding dust and acid-cleaning residue.

• Do not damage the label.

• There must be no material abrasion on the sealing edges. Material

abrasion will result in sharp-edged sealing contours and a damaged

seal.

• Check sealing contour for damage.

We recommend preparing a welding report.

6.7. Pressure/leak test

WARNING!

Danger of bursting.

Excess pressure can cause the hose to burst.

• Do not exceed specified pressure ranges (the see data sheet

BBS-04 Silicone hoses).

Risk of explosion.

Compressible media can cause explosions.

• Never perform pressure tests with compressible media (e.g. with

compressed air).

english

10

7. START-UP

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

product and the surrounding area.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• Observe the safety instructions and intended use.

• Only adequately trained personnel may start up the equipment/the

product.

• Following assembly, ensure a controlled restart.

• When starting up the equipment, ensure that no unauthorized volt-

age increases and pressure surges can occur.

NOTE!

Replace wearing parts in time

• The durability of the wearing parts is the responsibility of the plant

operator. Replacement of wearing parts in a timely manner must be

observed.

NOTE!

Damage to the sealing elements when cleaning the system.

• Clean the system preferably with a cleaning agent which does not

damage the sealing elements and silicone hoses.

• Do not clean with wire brushes or machines which cause abrasion

of the surface.

• When using mechanical pipeline monitoring devices, ensure

that they do not damage the sealing elements (also the sealing

contour).

Damaged sealing elements/hoses must be replaced.

To facilitate an absolutely sterile product cycle, the following points

have to be ensured:

• The sealing rings must be inserted.

• Metal supports must be absolutely clean.

• No damage to the sealing lips.

• The coupling must be tightened in a force-fitting manner.

english

Type BBS-04