Burkert Type 8750 User Manual

Page 9

I

NSTALLATION

8750 - 7

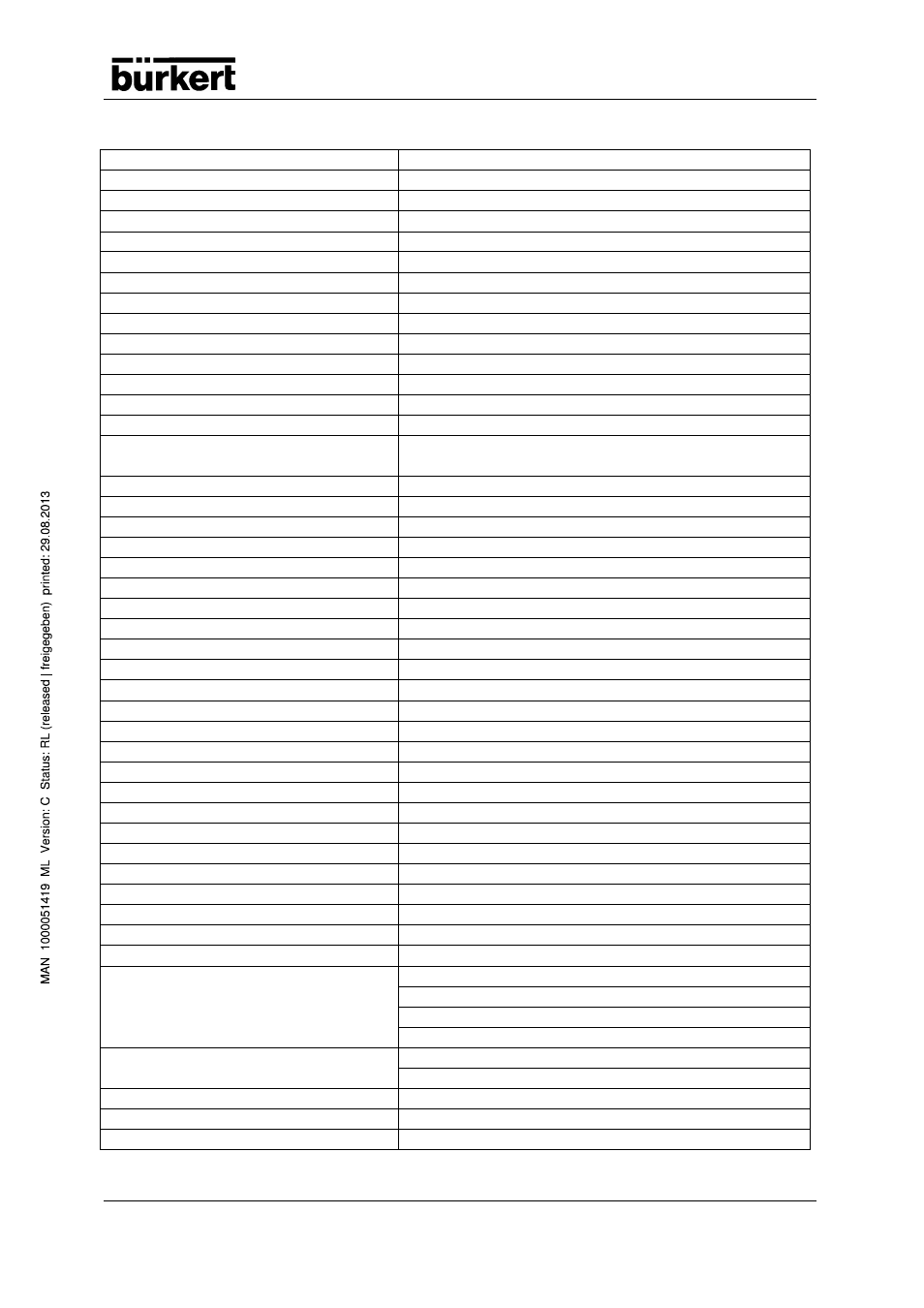

Technical data of the FMR Type 8750

Valve housing material

Stainless steal-investment casting 316L

Flange material

stainless steel 1.4301

Actuator material

polyamide (PA)

TopControl housing material

Noryl (PPE/PA)

Packed gland (with silicone grease)

PTFE-rings (with spring compensation)

Control plug

parabolic geometry for equipercentile characteristic

Seat reduction (orifices)

various Kvs-values for each connection size

Intake and outlet sections

to EN ISO 5167-1

Other parts contacting media

stainless steel 1.4571

Media

Standard

air and other gases

on request

steam and liquids

Media temperature

0 to +80 °C

Ambient temperature

-10 to +50 °C

Media pressure

0 to 6/10 or 16 bar

(depending on the pressure sensor range)

Control medium

instrument air to DIN ISO 8573-1

Dust content

• max. 40 µm particle size

Particle density

• max. 10 mg/m³

Pressure dew point

• -20 °C

Oil concentration

• max. 25 mg/m³

Intrinsic air consumption

0 l/min

Control air temperature

0 to +50 °C

Control air pressure

5.5 to 7 bar (DN15 to DN 65)

5 to 6 bar (DN80 and DN100)

Components

Control valve

Type 2712, SFA or SFB

Pressure sensors

Type 8323

TopControl Continuous

Type 8630 with process controller

Temperature transmitter

e.g. Type 1571, 0 to +150 °C

Pressure measurement range

0 to 6/10/16 bar, other ranges on request

Operating voltage

24 V DC

Residual ripple

10 %, not industrial DC!

Electrical connection

Operating voltage

circular connector, male, M12

External signals

circular connector, male, M16

Setpoint specification

0/4 to 20 mA or 0 to 5/10 V

Type of protection

IP65 to EN 60529

Display

LC display, 8-digit

Operating panel

3 function keys

Options

• binary input

• analog feedback

• binary outputs (alarm)

• bus communication (ProfibusDP or DeviceNet)

Process connections

flange to DIN EN 1092-1, ANSI, JIS; welding ends

to ISO 4200, DIN 11850 S2, BS 4825, ASME

Nominal diameters

DN15 to DN100, in the usual steps

Sensor assembly P1, P2, T

G 1/2 sleeve in the FMR tube

Measurement section

to DIN EN 60534-2-3