English – Burkert Type 1094 User Manual

Page 8

6 - 1094

english

one or more pulse generator

lines from the pulse generator/

petrol pump computer

Control electronics

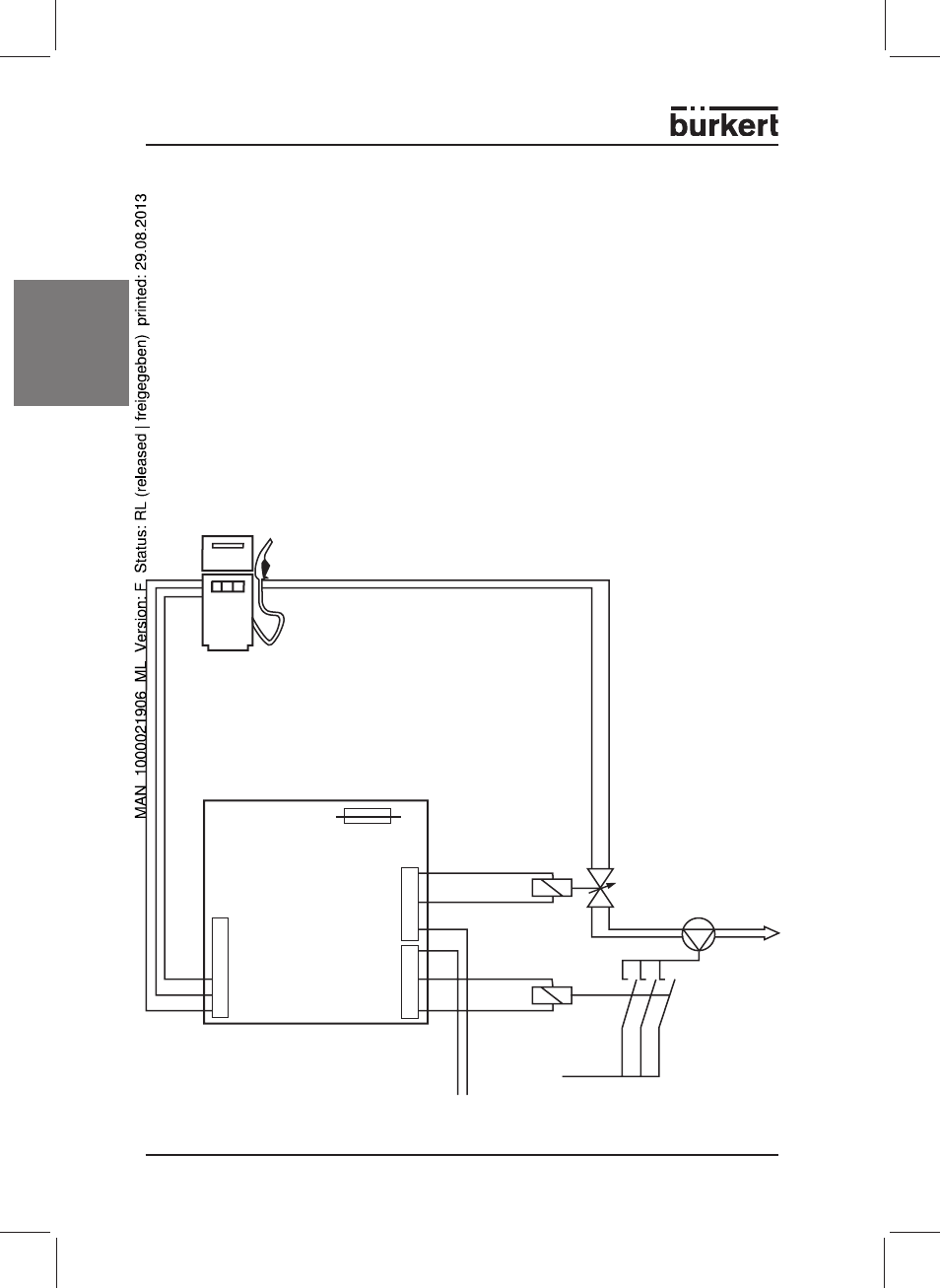

2.3 Principle of operation of a petrol pump with vapour recovery

The valve flow - gas flow characteristic of a pump installation is originally non-linear. In

order to ensure an even suction over the complete control range, a linear characteris-

tic is needed. To do this, various points on the characteristic are automatically stored

in the controller memory when dimensioning the installation with the control unit. The

number of points depends on the characteristic, and will be automatically determined

by the control unit. The correction of the characteristic also takes place automatically

through linear interpolation between these points.

At the start of the refuelling process, the quantity of petrol tanked will be calculated in

the controller from the measured pulse rate. Taking the linearised characteristic and

the K-factor of the suction rate into account, the set-value for the valve flow can now

be determined, and the proportional valve can be controlled for the suction of the

petrol vapour. Together with the control of the proportional valve, the vacuum pump

will also be put into operation to generate an underpressure. At the end of the refuel-

ling procedure, the petrol pump computer no longer generates any pulses and the

proportional valve for the vapour recovery will be closed. The vacuum pump will also

be switched off with an after-run time delay.

Figure 2: Functional diagram for a petrol pump with vapour recovery

Suction line

Proportional

valve

(Type 2332)

Vacuum pump

Power supply for the vacuum pump

24 V DC contactor/

relay for switching the

pump motor

24 V DC

power supply

(Type 1610)

To the

ground

tank