Fluidic installation – Burkert Type 8644 User Manual

Page 15

8644/Rockwell - 11

I

NSTALLATION

/ C

OMMISSIONING

Fluidic installation

ATTENTION!

The pneumatic connections shall not be pressurized during installation!

Make the connections with as large a volume as possible.

Close off unused, open ports with screw caps!

The ports for the pilot valve exhaust (x) shall not be closed off!

Check allocation according to instructions of ports 1 and 3 or 5: these shall under no

circumstances be swapped!

Procedure

Plug (D10) or screw (G 1/4, NPT 1/4) the connections, depending on the version, into the respective

service ports.

Safety notes

NOTE

For the plug connections the hoses must fulfil the following requirements:

•

Minimum hardness of 40 Shore D (to DIN 53505 or ISO 868);

•

Outside diameter to DIN 73378 (max. permissible deviation ± 0.1 mm from nominal

dimension);

•

Free from burrs, cut off at right angles and undamaged over outer circumference;

•

The hoses shall be pushed into the plug connectors as far as they will go.

Notes on plug connections

To release the hoses, depress the pressure ring and pull out the hose.

Disassembly of the plug connections

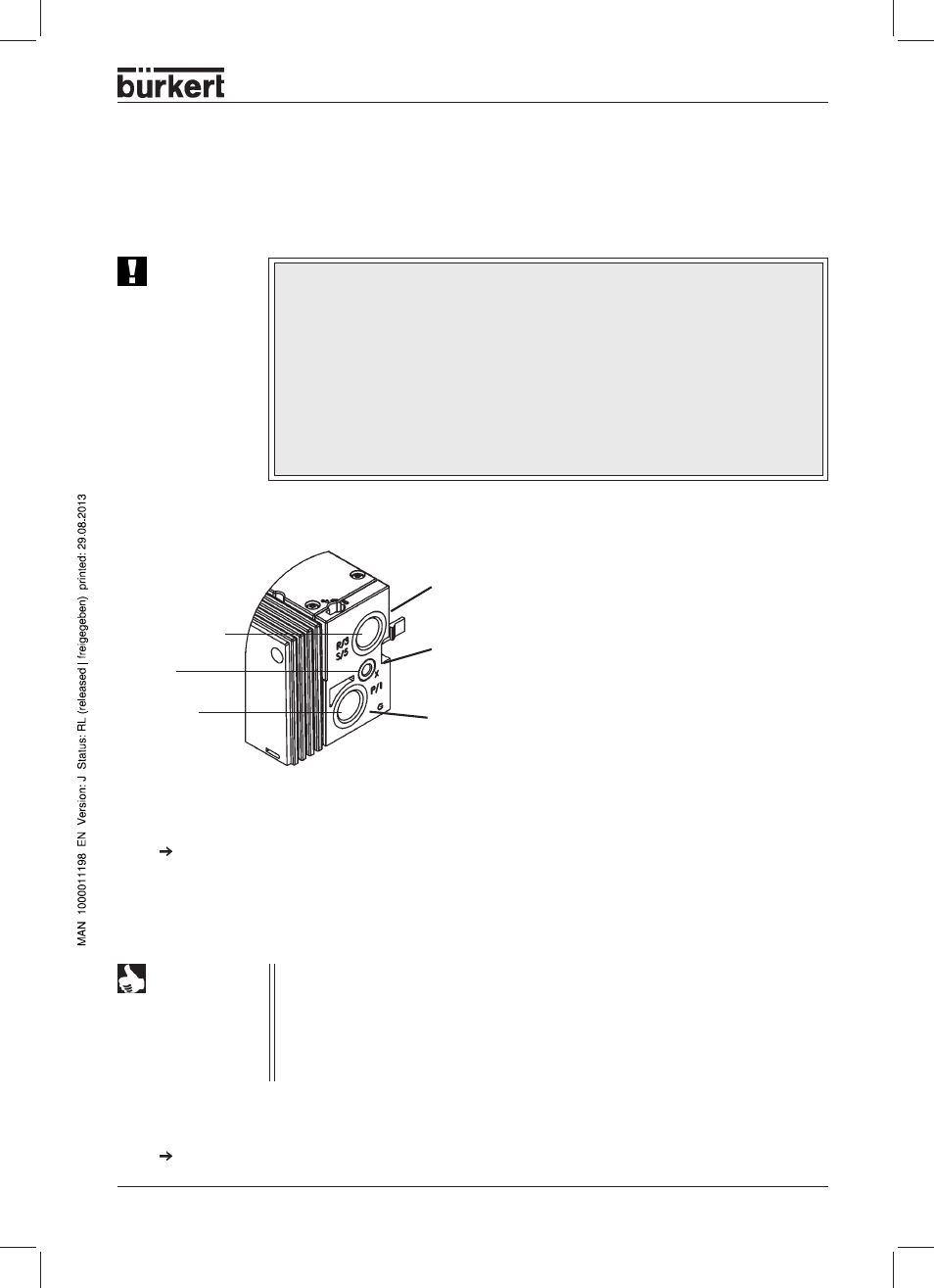

Pneumatic connections - supply units

Exhaust air

Standard model:

Venting of the pilot valves

Auxiliary air control model:

P-port for the pilot valves

Pressure supply port

(R/S) 3/5

X

(P) 1

W

W

W