Burkert Type 6650 User Manual

Page 6

20

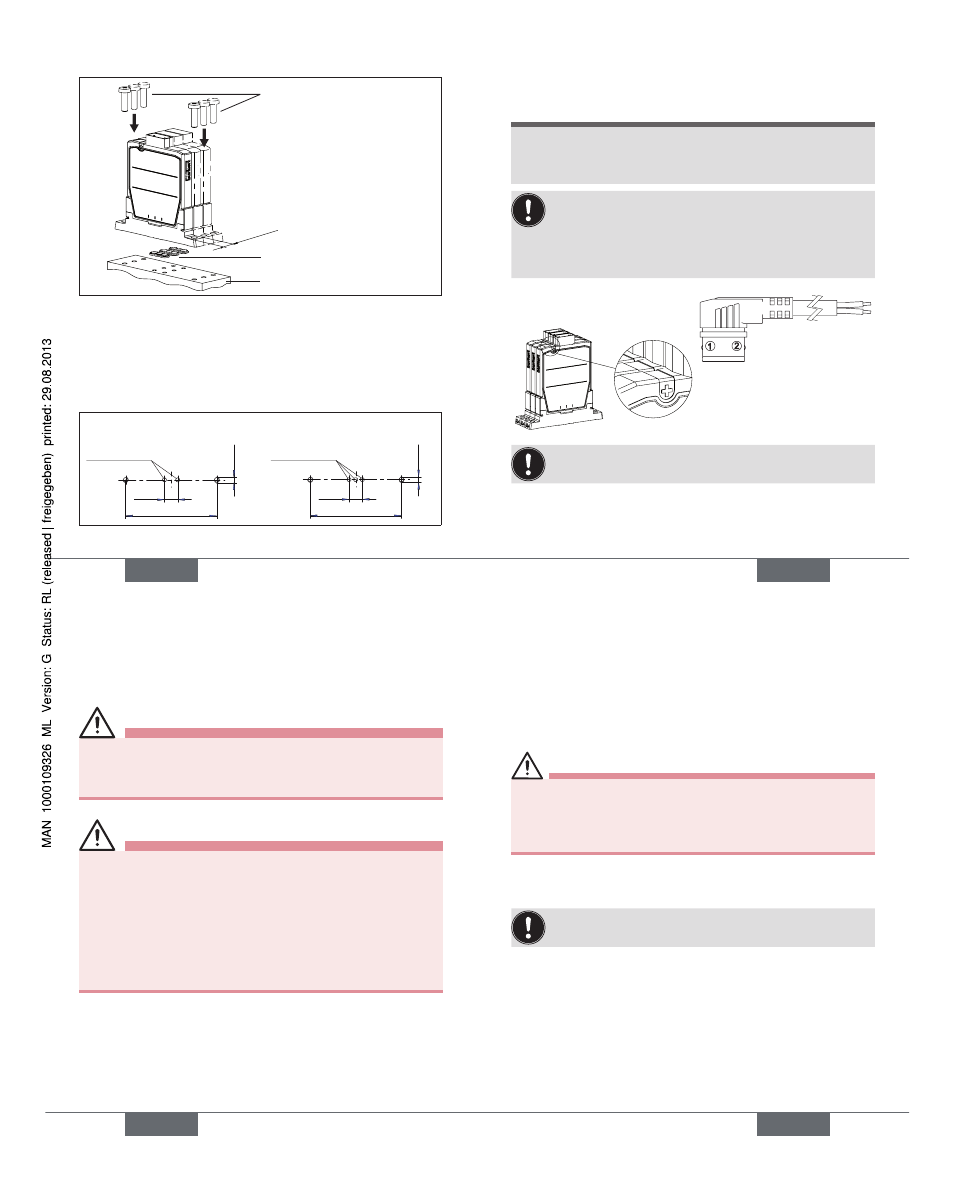

Sealing gasket

Manifold

4.5 mm

Flange screws

Recommended

torque:

0.24 Nm ± 0.04 Nm

→

Insert the sealing gasket into the valve.

→

Correctly allocate the fluid connection configuration 1,

2 and 3 to the valve and the manifold.

→

Screw valve onto the manifold.

Dimensional drawing for manifold:

4.8

33

M2

min. 6 deep

max. ∅ 1.4

2-way normally closed:

4.8

33

M2

min. 6 deep

max. ∅ 1.4

3-way universal function:

→

Check valve for leakage.

english

21

7.3. Electrical Installation

NOTE!

Without proper power reduction electronics, the valve

type 6650 is not suitable for continuous operation!

Please refer to the chapter titled "Electrical data".

In the block structure all valves must be poled iden-

tically. The mark (+) on the valve and the numerals

1 and 2 on the plug-in connector are used as orien-

tation. Example: On all units the plug-in connector

with numeral 2 points to the mark (+).

plug-in connector

1 = brown

2 = white

If the power reduction electronics are used, observe

the following polarity: brown + / white -

A type-specific plug-in connector with or without integrated

power reduction electronics is available as an accessory

(see data sheet).

english

21

22

8. MAINTENANCE,

TROUBLESHOOTING

8.1. Safety instructions

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

WARNING!

Risk of injury from improper maintenance!

• Maintenance may be carried out by authorised techni-

cians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

english

23

8.2. Maintenance Work

The valve is maintenance-free under normal operating

conditions.

If the exterior is very dirty, it is recommended to clean it

with suitable cleaning agents. If required, determine the

suitability of the cleaning agent by conducting a test.

WARNING!

Discharge of medium and malfunction if the con-

nection clamps are removed!

• The connection clamps between coil and fluid housing

must not be removed.

8.3. Malfunctions

If operating with power reduction electronics,

ensure that the power supply flank is quick enough.

If malfunctions occur, check

→

the line connections

→

the operating pressure

→

the power supply and valve control

If the valve still does not switch, please contact your

Bürkert Service.

english

23

Type 6650