Installation – Burkert Type 6650 User Manual

Page 5

16

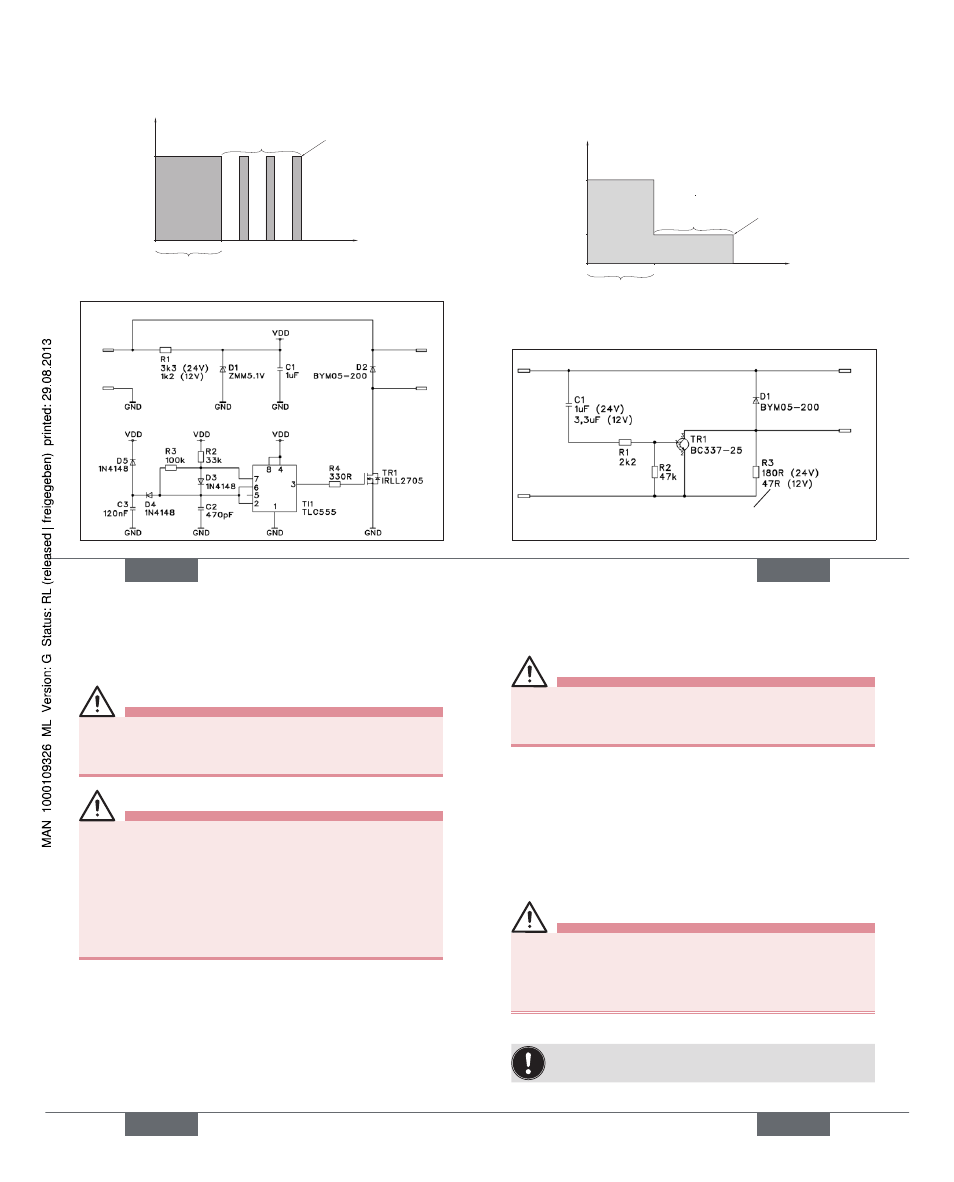

• in case of a PWM voltage drop:

Duty cycle 33 %, f=20kHz

PWM-signal

20 kHz

switch-off point

switch-on pulse

5 ms

0

100 %

U

t

For OEM electronics (PWM) recommended circuit diagram:

valve

supply voltage

Circuit diagram for 24 V design

english

17

• for resistance reduction:

Switch-on pulse 100 % nominal voltage for 5 ms, then

holding voltage 35 % nominal voltage

switch-off point

Switch-on pulse

5 ms

0

100 %

U

35 %

holding voltage

t

For OEM electronics (resistance reduction) recommended

circuit diagram:

Caution : Drop approx. 1.6 W

Alternatively series or parallel connection of several resistors

Connection

coil

Circuit diagram for 24 V design

english

17

18

7. INSTALLATION

7.1. Safety instructions

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorised techni-

cians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

english

19

7.2. Fluid Installation

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Installation position: any, actuator preferably upwards.

Procedure:

→

Before installation, clean any possible dirt off the pipe-

lines and flange connections.

→

Install a dirt trap to prevent malfunctions (Mesh size:

5 µm).

WARNING!

Danger through spillage of medium!

Leaking connections if seal seated incorrectly.

• Ensure that the supplied sealing gasket is seated

correctly!

The add-on dimension must not fall short of 4.5 mm!

english

19

Type 6650