Burkert Type 3239 User Manual

Page 17

17

Installation

procedure:

→

Cross-loosen fastening screws and remove actuator with dia-

phragm from the body.

→

Weld or glue body in the pipeline.

→

After welding or gluing in the body, smooth the body surface (if

required) by grinding.

→

Clean the body carefully.

→

Place actuator on the body.

→

Lightly cross-tighten the fastening screws until the diaphragm is

between the body and actuator.

Do not tighten screws yet.

→

Activate the diaphragm valve twice to position the diaphragm

correctly.

→

Tighten the fastening screws up to the permitted tightening

torque (see tables in chapter „8.3.2 Tightening torques for

diaphragms“).

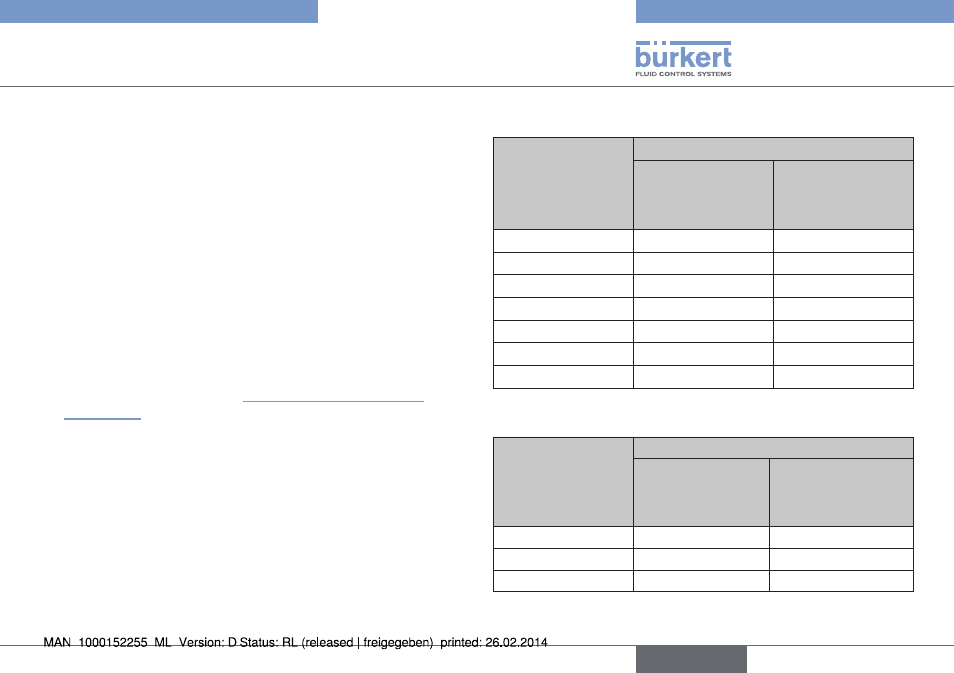

8.3.2 Tightening torques for diaphragms

Orifice

(diaphragm size)

dn [mm]

actuator pps or stainless steel

diaphragm

epdm / fkm

diaphragm

ptfe/advanced

ptfe/laminated

advanced ptfe

8

2

2,5

15

3,5

4

20

4

4,5

25

5

6

32

6

8

40

8

10

50

12

15

Tab. 8: Tightening torques for diaphragms. Actuator PPS or

stainless steel

Orifice

(diaphragm size)

dn [mm]

actuator stainless steel

diaphragm

epdm / fkm

diaphragm

ptfe/advanced

ptfe/laminated

advanced ptfe

65

20

30

80

30

40

100

40

50

Tab. 9: Tightening torques for diaphragms. Actuator stainless steel

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239