English, Media, Construction of the control valve – Burkert Type 2712 User Manual

Page 8

T

ECHNICAL

D

ATA

6 - 2712

english

Liquid and gaseous media that do not attack the housing and seal materials.

Control medium:

instrument air, class 3 according to DIN ISO 8573-1

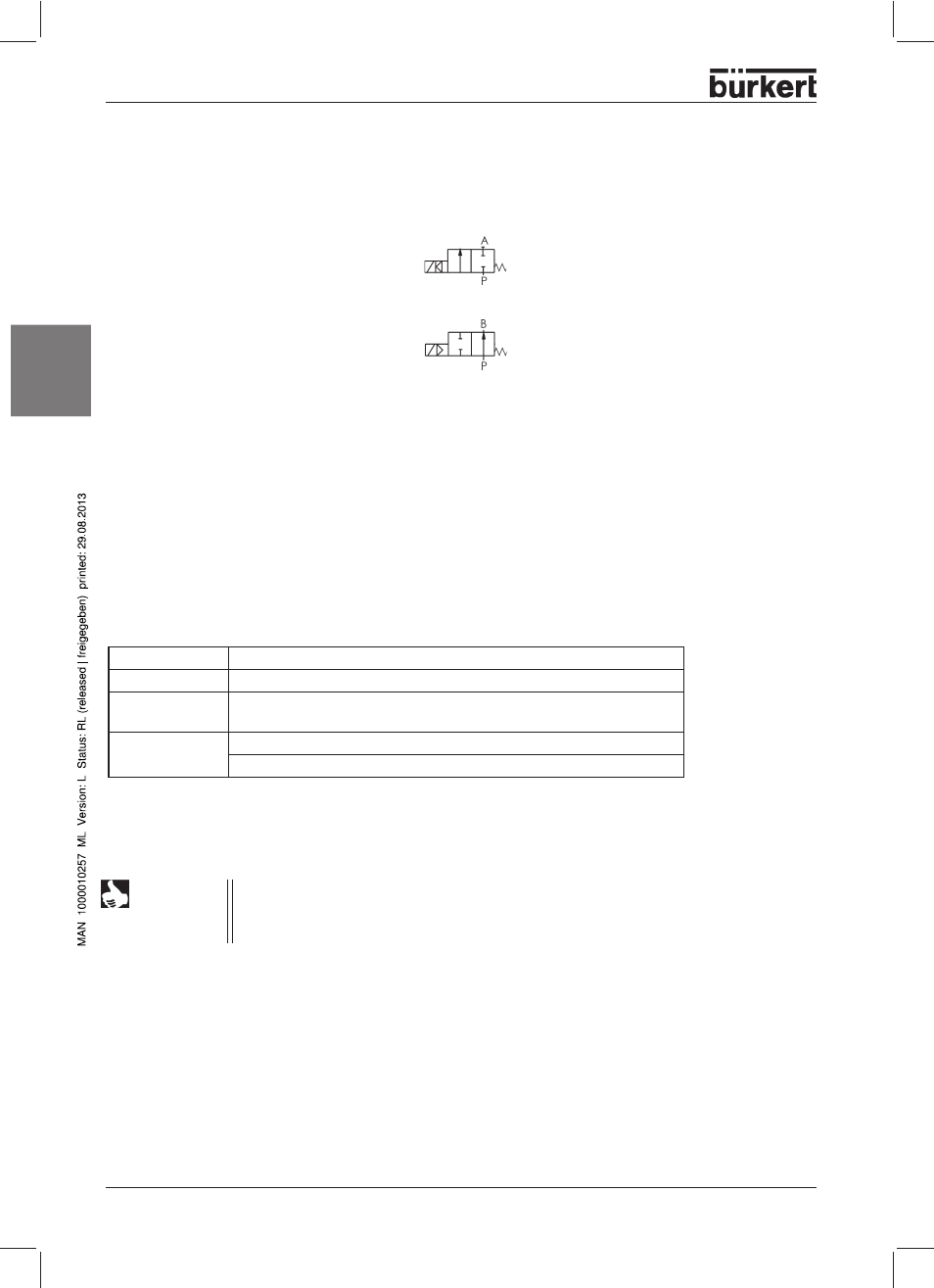

2/2-way piston controlled valve with control cone and flat-seat housing

Control function A

(closed by spring force in rest position)

Control function B

(open in rest position)

Drive unit material:

PA (polyamide)

Housing material:

stainless steel 316L

Seal materials:

steel/steel (1.4571) or PTFE/steel

Media

NOTE

The approved operating pressures and media temperatures are to be taken from the data

sheet or rating plate. With regard to the permissible seat leakage, the values given in DIN

EN 1349 are complied with, whereby for the steel/steel seal, leakage class IV and for the

PTFE/steel seal leakage class VI apply.

Construction of the control valve

Control medium

Quality classes according to DIN ISO 8573-1

Dust content

Class 5: Max. particle size 40 µm; max. particle density 10 mg/m

3

Water content

Class 3: Max. pressure dew point -20 °C or min. 10 degrees below the

lowest operating temperature

Oil content

Class 5: Max. 25 mg/m

3

in conjunction with Bürkert positioners

Class 3: Max. 1 mg/m

3

in conjunction with SIDE Control Type 8635

Note: Higher demands placed on the positioner must be observed!