Hsi lg ne replacement of valve seat – Burkert Type 2712 User Manual

Page 16

M

AINTENANCE

AND

S

ERVICING

OF

THE

V

ALVE

14 - 2712

hsi

lg

ne

Replacement of valve seat

The drive unit must be completely removed to replace the valve seat.

Disassembly

Remove the electrical and pneumatic supplies from the Top

Control.

Pull off the pneumatic hose between Top

Control and drive unit at control connection of drive unit.

In the case of control function A, pressurize the lower control connection of the drive unit with

compressed air (5 to 7 bar) so that the control cone lifts from the valve seat and is not damaged. With

control function B, no compressed air must be applied for this purpose.

Remove the drive unit in the open valve position by unscrewing the threaded nipple of the housing.

Before reinstalling the drive (in open valve position), grease the nipple thread with stainless steel

lubricant, e.g. silicone grease CKS 1110 from OKS, Munich and replace the graphite seal.

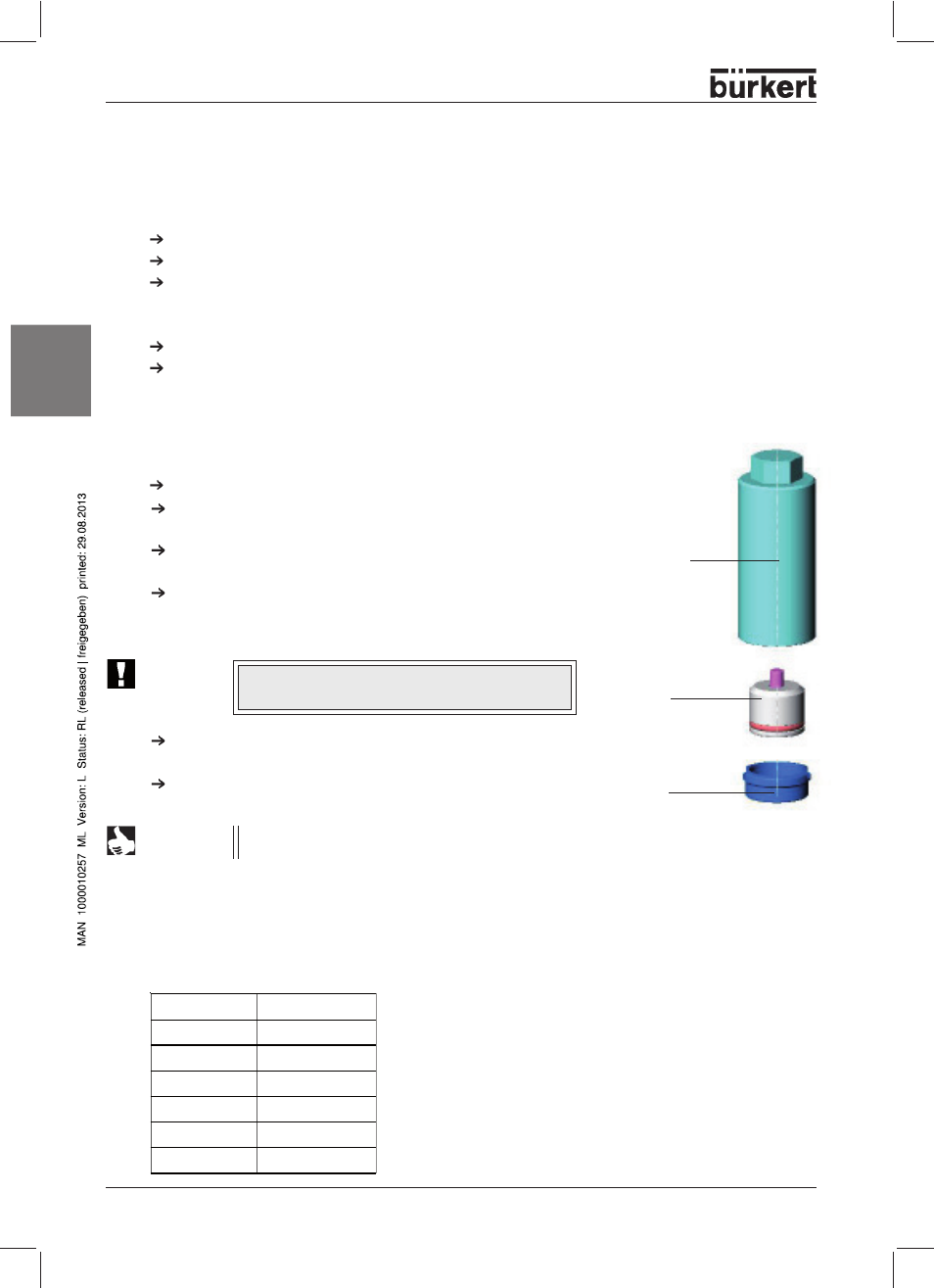

Assembly tool

Tool insert

(depending on nomi-

nal diameter of seat)

Valve seat

Replacement of valve seat

Unscrew the old housing seat using the assembly tool and a

spanner.

Clean thread and sealing surface in the housing with

compressed air.

Select a tool insert and screw it into the assembly tool.

Push the new seat onto the assembly tool, grease the thread

with stainless steel lubricant, e.g. Klüberpaste UH1 96-402

from Messrs. Klüber.

Place the attached seat by hand into the housing thread and

screw it in.

Tighten the seat with a torque wrench to the torque specified.

ATTENTION!

For special applications such as for oxygen and

analysis, use only the approved lubricants.

NOTE

On installing a valve seat with a different nominal

diameter, the order number for the valve changes!

Assembly

Assembly is carried out in the reverse sequence to

disassembly.

Housing DN

Order no.

15

652 604

20

652 605

25

652 606

32

652 607

40

652 608

50

652 609

Seat assembly tools