Malfunctions, Replacing the control cone – Burkert Type 2712 User Manual

Page 14

M

AINTENANCE

AND

S

ERVICING

OF

THE

V

ALVE

12 - 2712

h

si

l

g

n

e

Possible malfunctions concerning the actuator are listed in the operatinginstructions for the Top

Control.

Malfunctions

ATTENTION!

Repairs to the actuator may only be carried out in the factory. Contact your Bürkert

branch or our Customer Service directly:

Bürkert Fluid Control Systems

Service Department

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: (07940) 10 91-111

Fax: (07940) 10 91-448

E-Mail: [email protected]

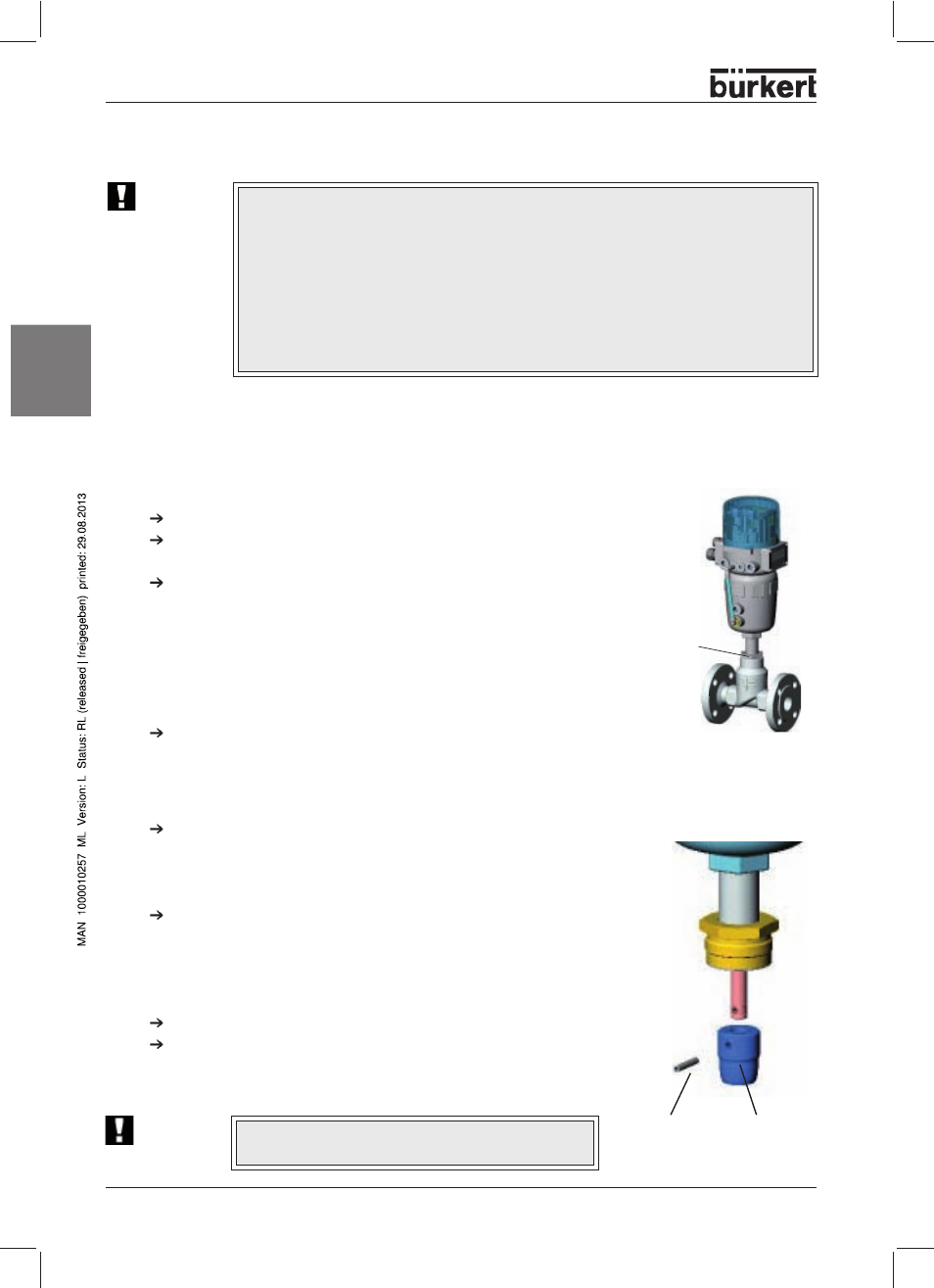

Replacing the control cone

Replacing the control cone:

Knock out the dowel pin with a suitable driver.

Driver diameter:

up to DN 25

φ

4 mm

from DN 32 to DN 65

φ

5 mm

Pull off the control cone with the aid of two metal strips of equal

height that are clamped to the left and right of the spindle between

the control cone and the threaded nipple of the actuator. To pull off

the control cone, apply compressed air (approx. 6 bar) to the lower

control connection of the actuator.

Place the new control cone onto the end of the spindle.

Align the bores to each other.

On the fluidic side, the control cone can be replaced in case of wear or damage. For this purpose, the

actuator must be disassembled from the housing.

ATTENTION!

Do not damage the sealing surface or the control

contour!

dowel pin

control cone

Disassembly

Remove the electrical and pneumatic supplies from the TopControl.

Pull off the pneumatic hose between TopControl and actuator at the

control port of the latter.

Control function A:

Pressurize the lower control port of the actuator with compressed

air (6 bar), so that the control cone is liftet from the valve seat and

is not damaged.

Control function B:

With control function B, no compressed air must be applied for this

purpose.

Remove the actuator in the open valve position by unscrewing the

threaded nipple from the housing.

threaded nipple