Burkert Type 2658 User Manual

Page 16

16

Installation

Use only those adhesives which are suitable for joining PVC

products.

After applying the adhesive, wait at least 24 hours before con-

→

ducting a pressure test.

heating element socket welding

7.2.2.

(pp-h, pVdF)

Procedure:

Chamfer the pipe ends by approx. 15°.

→

Check outer diameter of pipe / inner diameter of the socket

→

according to the following table.

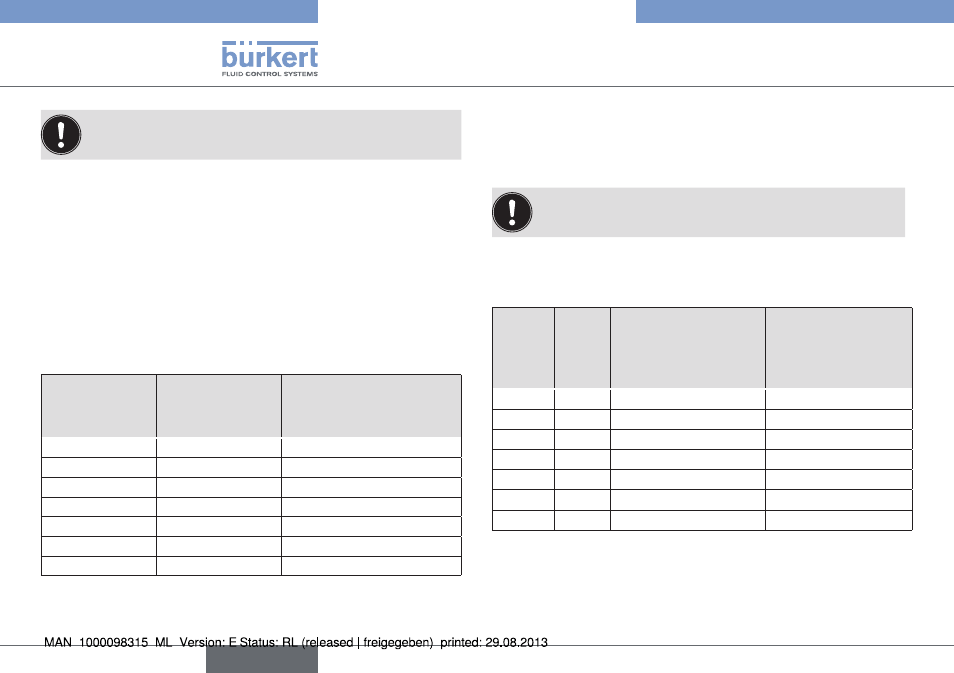

nominal width

dn

[mm]

pipe

outer Ø

[mm]

socket

inner Ø

[mm]

10

16

15.85 ... 15.95

15

20

19.85 ... 19.95

20

25

24.85 ... 24.95

25

32

31.85 ... 31.95

32

40

39.75 ... 39.95

40

50

49.75 ... 49.95

50

63

62.65 ... 62.95

Set the temperature controller of the welding equipment to

→

250 - 270 °C.

Observe the warming-up time, welding time and cooling- down

→

time according to the following tables.

Leave the welded joints to cool down always at room

temperature!

Welding parameters

nominal

width

dn

[mm]

pipe

outer

Ø

[mm]

Minimum thickness

[mm]

Warming up time

[s]

10

16

2.5 (PP-H) - 1.5 (PV DF)

5 (PP-H) - 4 (PV DF)

15

20

2.5 (PP-H) - 1.9 (PV DF)

5 (PP-H) - 4 (PV DF)

20

25

2.7 (PP-H) - 1.9 (PV DF)

7 (PP-H) - 8 (PV DF)

25

32

3.0 (PP-H) - 2.4 (PV DF) 8 (PP-H) - 10 (PV DF)

32

40

3.7 (PP-H) - 2.4 (PV DF) 12 (PP-H) - 12 (PV DF)

40

50

4.6 (PP-H) - 3.0 (PV DF) 16 (PP-H) - 18 (PV DF)

50

63

3.6 (PP-H) - 3.0 (PV DF) 24 (PP-H) - 20 (PV DF)

english

Type 2657