Burkert Type 2101 User Manual

Page 10

10

Installation

Type 2101

7.2. before installation

• The globe valve can be installed in any installation position, pref-

erably with the actuator face up.

• Before connecting the valve, ensure the lines are flush.

• Observe direction of flow (see type label).

7.2.1. Preparatory work

→

Clean pipelines (sealing material, swarf, etc.).

devices with welded body

Remove the actuator from the valve body:

→

Clamp the valve body in a holding device.

note!

damage to the seat seal or the seat contour!

• When removing the actuator, ensure that the valve is in open

position.

→

Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→

Using a suitable open-end wrench, place the wrench flat on the

tube.

→

Unscrew the actuator from the valve body.

other device versions

→

Do not remove actuator unless this is a customer-specific

requirement.

→

Procedure see “Devices with welded body”.

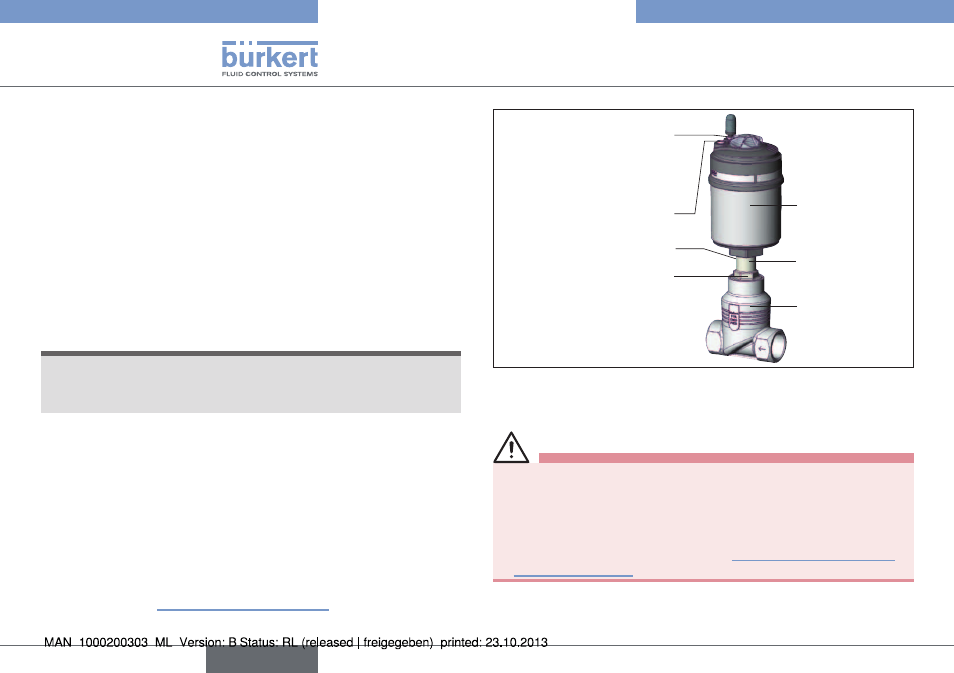

Actuator

Nipple

Valve body

Air discharge connection

CFA, CFB

Pilot air port

CFI

Pilot air port

CFA, CFB, CFI

Flats for open-end

wrench

Release bore

2

1

Fig. 2:

Installation

7.3. installation

Warning!

risk of injury from improper assembly!

Assembly with unsuitable tools or non-observance of the tight-

ening torque is dangerous as the device may be damaged.

• For installation use an open-end wrench, never a pipe wrench.

• Observe the tightening torque (see “Tab. 4: Tightening torque

english