Burkert Type 2300 User Manual

Page 2

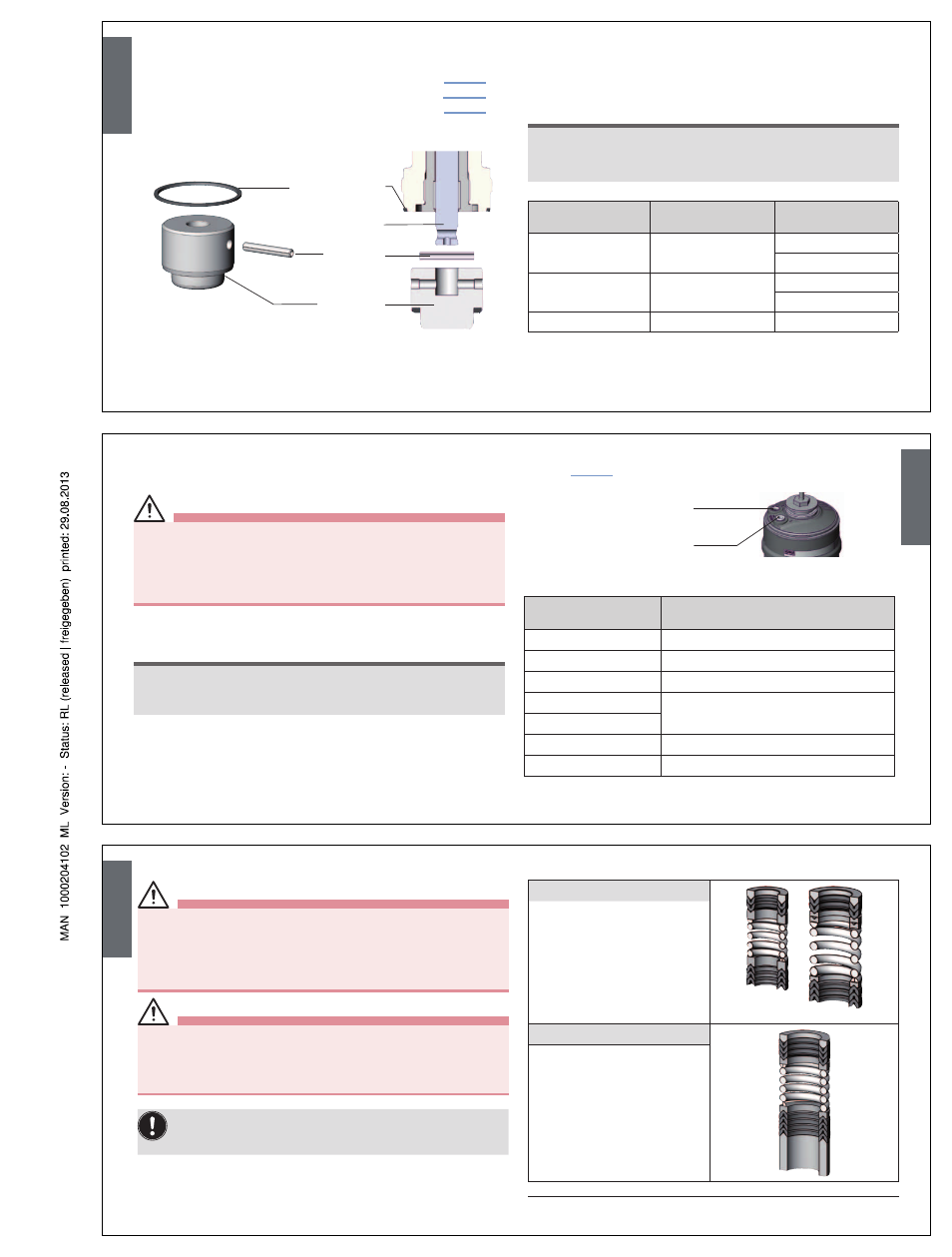

Replace the control cone set:

→

Knock out dowel pin with a suitable pin punch.

Pin punch ø 4 mm, for spindle diameter 10 mm (see “Tab. 1”).

Pin punch ø 5 mm, for spindle diameter 14 mm (see “Tab. 1”).

Pin punch ø 6 mm, for spindle diameter 22 mm (see “Tab. 1”).

→

Remove control cone

.

Spindle

Dowel pin

Control cone

Graphite seal

→

Attach new control cone to the spindle.

→

Align bores of the control cone and spindle.

→

Support control cone on the cylindrical part with the aid of a prism

or something similar.

→

Put on dowel pin and carefully knock in with a hammer.

→

Position the dowel pin in the centre of the spindle axis.

note!

Important information for the problem-free and safe functioning

of the device!

• The sealing face of the control cone must not be damaged.

Spindle

ø

Orifice

Actuator size

10

15 - 32

ш 50

ш 70

14

25 - 50

ш 90

ш 130

22

65

ш 130

Tab. 1: Spindle ø in reference to orifice and actuator size

english

Install the actuator (with control unit) on the valve body:

→

Check the graphite seal and if required, replace it.

WArnInG!

Danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen appli-

cations there is a risk of an explosion!

• In specific applications, e.g. oxygen or analysis applications, use

appropriately authorised lubricants only.

→

Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

note!

Damage to the seat seal or the seat contour!

• When installing the actuator, ensure that the valve is in open

position.

→

Control function A:

Without unit control: pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

With unit control: open the valve according to the operating

instructions for the control unit.

→

Screw actuator into the valve body. Observe tightening torque

(see “Tab. 2”).

1

2

Pilot air port

Tightening torque

Orifice

(mm)

Tightening torque

[Nm]

15

45 ± 3

20

50 ± 3

25

60 ± 3

32

65 ± 3

40

50

70 ± 3

65

100 ±3

Tab. 2: Tightening torque of valve body / nipples

english

changing the Seal Set

WArnInG!

Risk of injury if the wrong tools are used!

It is dangerous to use unsuitable tools for installation work as the

device may be damaged.

• To remove the actuator from the valve body, use an open-end

wrench, never a pipe wrench.

DAnGer!

Risk of injury from discharge of medium and pressure!

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

• Before removing a device, switch off the pressure and vent the lines.

Before the packing gland can be replaced, the actuator

must be removed from the valve body and the control cone

removed.

The seal set for the packing gland contains:

SP10 / SP14

SP10

SP14

• 1 support ring

• 5 chevron seals

• 2 or 3 pressure rings

1)

• 1 pressure spring

• 1 graphite seal

• Lubricant

SP22

• 1 support ring

• 7 chevron seals

• 2 pressure rings

• 1 pressure spring

• 1 spacer

• 1 graphite seal

• Lubricant

1)

Depending on the spindle diameter (10 mm or 14 mm)

english