Actuators k-175, l225 – Burkert Type 2033 User Manual

Page 14

14

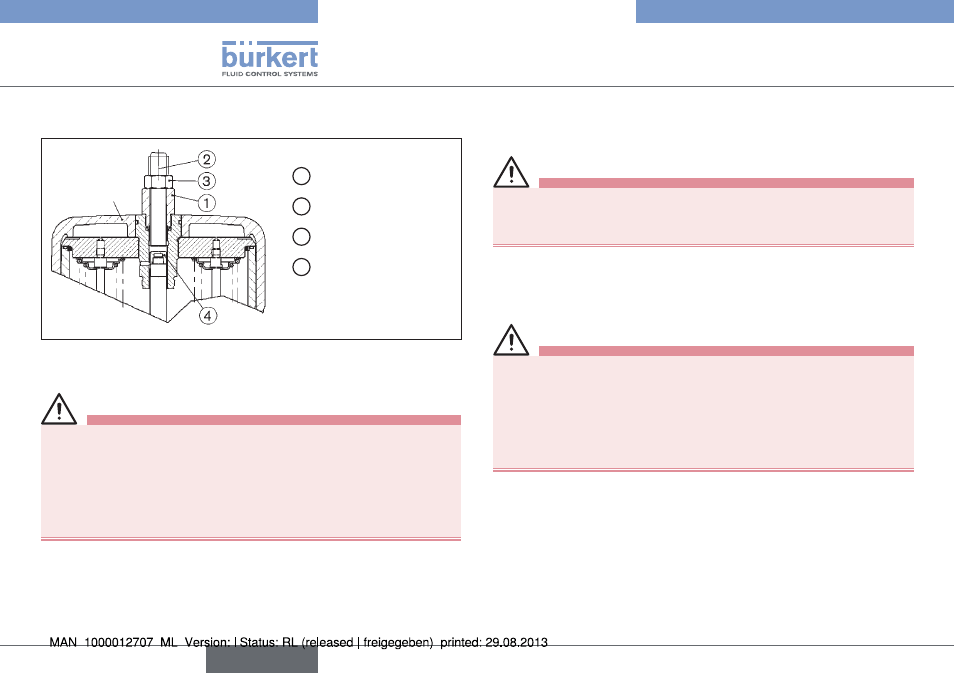

Option: Maximum stroke limitation

7.3.

Actuators K-175, L225

Actuator

Parts required

1 Threaded nipple

2 Setscrew M16 x 80

3 Nut M16

4 Spindle cap

Fig. 5: Actuators K-175, L-225,

maximum stroke limitation without position repeater

WARNING!

Risk of injury and functional failure due to derailed or slipped

parts!

The actuators contain pre-tensioned springs that may derail or slip

on improper opening.

• Actuators K-175 and L-225 shall only be opened in our factory

or by the responsible distributor.

7.3.1. Work to be carried out before

installation

DANGER!

Hazard due to high pressure!

• Interrupt the control air and fluid infeed before modifying the

devices and reduce the pressure in the fluid system.

→

Interrupt supply of medium.

→

Empty valve housing.

→

Bring actuator into the upper piston position.

DANGER!

For control function A and I:

Risk due to high pressure when screwing on the visibility

hood!!

The visibility hood must not be pressurized during attachment.

• Therefore pressurize only the lower piston area via the lower

control air connector using compressed air.

→

Unscrew transparent cap from actuator cover.

→

Screw out position indicator (yellow screw cap) by hand.

→

Screw threaded sleeve or spindle cap

④ instead of the position

indicator onto the end of the spindle (WAF14).

→

Interrupt supply of control air.

english

Type 2000, 2002, 2012

2030, 2031; 2032, 2033