Chemical injection supply system, Warning – Alliance Laundry Systems PHM1397C User Manual

Page 46

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

Specifications and Dimensions

F8112101

44

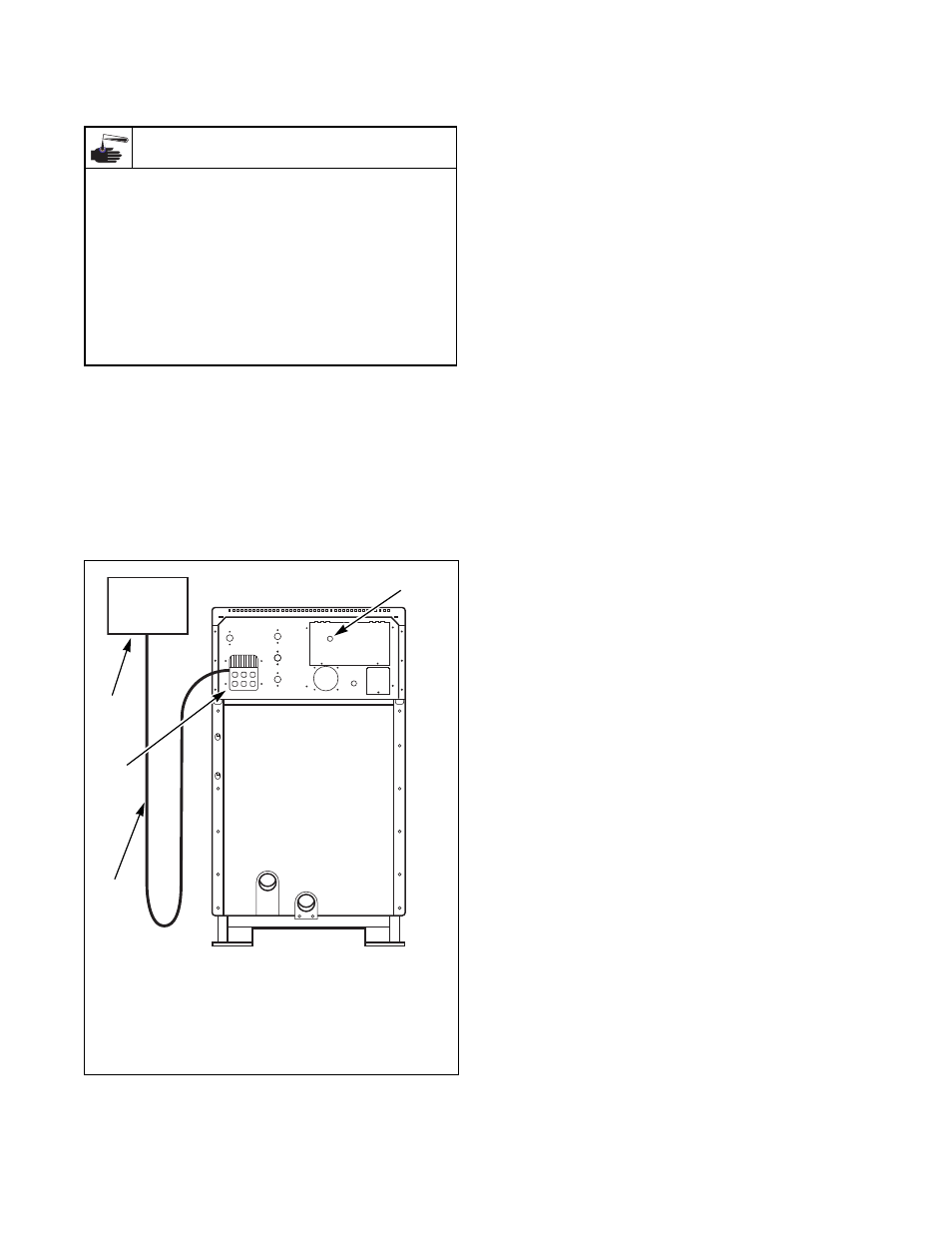

Chemical Injection Supply System

Undiluted chemical dripping can damage the washer-

extractor. Therefore, all chemical supply dispenser

pumps should be mounted below the washer’s

injection point. All dispenser tubing should also run

below the injection point. Loops do not prevent drips

if these instructions are not followed. Failure to follow

these instructions could damage the machine and void

the warranty. Figure 19 shows a typical chemical

injection supply system.

Chemical Service Connections

Chemical service connections are located inside the

machine’s rear electrical enclosure. Provisions

include:

• Clearly marked chemical signal locations.

• Chemical signals are prewired for 85 VAC

signals (85 VAC on, 0 VAC off) and can be easily

changed to accommodate dry contact chemical

signal formats.

• Up to 12 chemical signals are available.

• A timer hold input is available for use with

dispensing systems feeding multiple machines.

• 7/8 in. (22 mm) hole is provided in rear electrical

panel cover for mounting a typical chemical

pump interface module or feeding chemical

pump control signal wires.

Connection of Chemical Supply Hoses

To connect a chemical supply hose to machine:

1. Remove one of the plastic plugs from an

injection port.

2. Screw one of the 6 3/8 in. (10 mm) nipples

supplied with machine into open injection port.

3. Connect feed hose to nipple and secure hose with

a hose clamp.

4. Ideally, pump system should be mounted so that

it is lower than chemical injection ports. Hose

connections at injection port should be highest

point in hose to prevent chemical drippage. Refer

to Figure 19. Making loops in chemical feed

hoses does not prevent dripping.

PHM689N

1

Chemical Signal Connections

2

Supply Hose

3

Chemical Injection Connections

4

Dispenser Pump

Figure 19

Wear eye and hand protection when

handling chemicals; always avoid direct

contact with raw chemicals. Read the

manufacturer’s directions for accidental

contact before handling chemicals.

Ensure an eye-rinse facility and an

emergency shower are within easy reach.

Check at regular intervals for chemical

leaks.

SW016

WARNING

Dispenser

Pump

1

3

2

4