Burkert Type 0290 User Manual

Page 4

8

max. 1 Nm

Seal

Authorized cable plug

e.g. Type 2508 or other suitable

cable plug in accordance with

DIN EN 175301-803 Form A

Fig. 1:

Electrical installation

→

Tighten cable plug (for permitted types see data sheet), observing

max. torque 1 Nm.

→

Check that seal is fitted correctly.

→

Connect protective conductor and check electrical continuity between

coil and body.

6

MAINTENANCE, TROUBLESHOOTING

6.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

WARNING!

Risk of injury from improper maintenance!

▶ Maintenance may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

english

9

6.2 Malfunctions

If malfunctions occur, check whether:

• the device has been installed according to the instructions,

• the electrical and fluid connections are correct,

• the device is not damaged,

• all screws have been tightened,

• the voltage and pressure have been switched on,

• the pipelines are clean.

Malfunction

Possible cause

Valve does not

switch

Short-circuit or coil interrupted

Medium pressure outside the permitted

pressure range

core / core area is dirty

Valve does not close Internal space of the valve is dirty

If the valve still does not switch, please contact your Bürkert Service.

7

SPARE PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries and

damage the device and the surrounding area.

▶ Use only original accessories and original spare parts from Bürkert.

7.1 Ordering spare parts

The spare parts sets SET 1 (coil set) or SET 3 (wearing parts set) can

be ordered by quoting the identification number of the device.

english

10

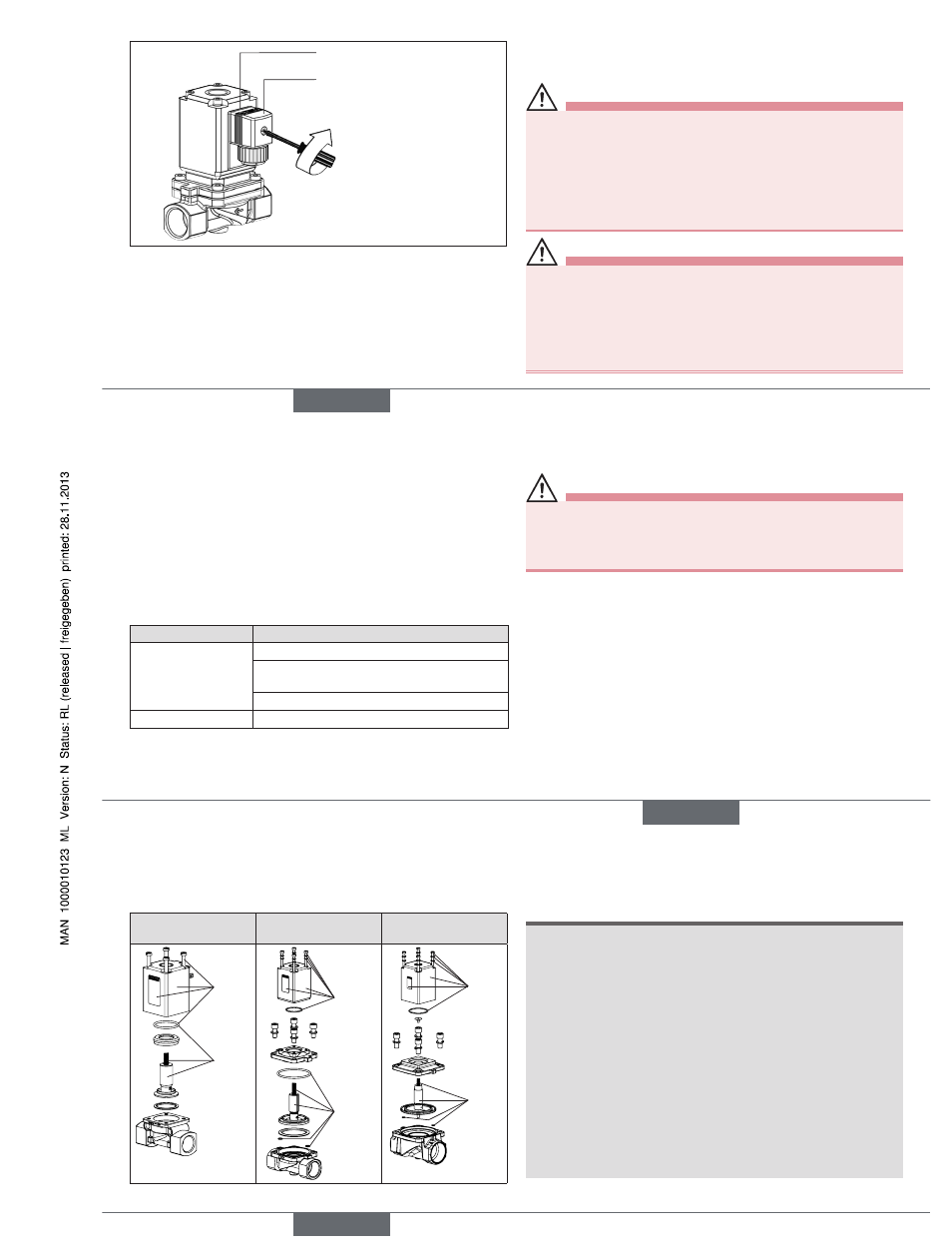

7.2 Overview of replacement spare sets

SET 1 = coil set

SET 3 = wearing parts set

DN 12

DN 20, DN 25

DN 32, DN 40,

DN 50, DN 65

SET 1

SET 3

SET 1

SET 3

SET 1

SET 3

Fig. 2:

Overview of replacement spare sets

8

PACKAGING, TRANSPORT,

STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature -40 ... +55 °C.

Damage to the environment caused by device components con-

taminated with media.

• Dispose of the device and packaging in an environmentally friendly

manner.

• Observe applicable regulations on disposal and the environment.

english

Type 0290