6 unbalance optimisation, 7 automatic minimization of static unbalance, 8 eccentricity measurement (option) – CEMB USA C72_2SE EVO (B) User Manual

Page 14: English

14

s

sx

x

g

g

g

g

d

dx

x

5

50

0°°

s

sx

x

g

g

g

g

d

dx

x

4

4 g

g

3

3 g

g

1

1 g

g

6

6 g

g

s

sx

x

g

g

g

g

d

dx

x

s

sx

x

g

g

g

g

d

dx

x

s

sx

x

g

g

g

g

d

dx

x

A

B

Use and maintenance manual Rev. 12-2009

ENGLISH

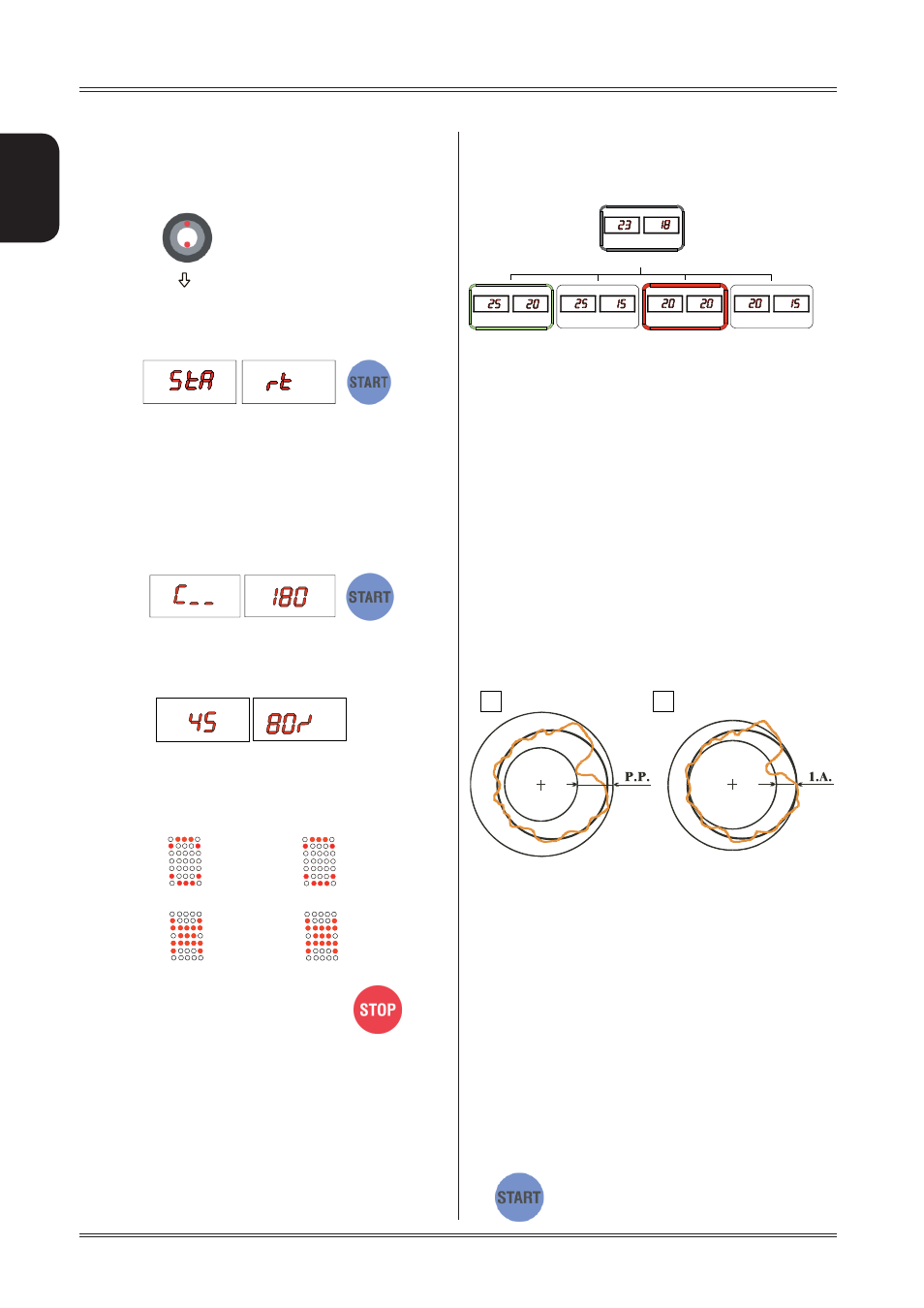

5.6 UNBALANCE

OPTIMISATION

This operation is performed to reduce the static unba-

lance of the wheel.

It is suitable for static unbalance values in excess of 30

grams.

I

a. f no unbalance was measured before, START appears

on the display. Press this button to proceed.

Mak

b.

e a reference mark on the flange and the rim (using

a piece of chalk, for example).

With the aid of a tyre remover, turn the tyre on the rim

by 180°.

Refi t the wheel in such a way that the reference marks

on the rim and the fl ange coincide.

Press START to begin reading.

RH displ

c.

ay: percentage reduction value

LH display: actual static unbalance value which can be

reduced by rotation

Ma

d.

rk the two positions of the rim and tyre, and turn the

tyre on the rim until the positions coincide to achieve

the optimisation shown on the display

To cancel optimisation at any time, press

.

5.7 AUTOMATIC MINIMIZATION OF STATIC

UNBALANCE

This program is designed to improve the quality of balancing

without any mental effort or loss of time by the operator. In

fact by using the normal commercially available weights, with

pitch of 5 in every 5 g, and by applying the two counterweights

which a conventional wheel balancer rounds to the nearest

value, there could be a residual static unbalance of up to 4

g. The damage of such approximation is emphasized by the

fact that static unbalance is cause of most of disturbances

on the vehicle. This new function, resident in the machine,

automatically indicates the optimum entity of the weights

to be applied by approximating them in an “intelligent” way

according to their position in order to minimize residual static

unbalance.

5.8

ECCENTRICITY MEASUREMENT

(OPTION)

The much enlarged fi gures show the outer tyre surface

and axis of wheel rotation.

Fig. A - shows measurement of the total Peak-to-Peak

eccentricity defi ned as maximum radial deviation of the tyre

surface.

Fig. B - shows measurement of the eccentricity of the 1st

harmonic, i.e. the eccentricity of that circle which “recopies”

the tyre shape, by averaging the local deviations of the tyre

from the round shape.

Obviously the P.P. measurement is normally greater than that

of the 1st harmonic. Tyre manufacturers normally supply two

different tolerances for the two eccentricities.

The radial eccentricity measurements is automatically carried

out after the unbalance measurement without having to go into

particular procedures. Remember to position the sonar sensor

in front of the surface to be measured before pressing

the

button.

Initial unbalance

Phase shift

Possible approximations

static residue

static residue

static residue

static residue

With traditional wheel

balancer

Choice with minimum static

unbalance

Use of the wheel balancer

RIM

POSITION

TYRE

POSITION