1 modifying set dimensions, 2 measurement result – CEMB USA C72_2SE EVO (B) User Manual

Page 12

12

FI

FE

Use and maintenance manual Rev. 12-2009

ENGLISH

Press the button

to perform a spin.

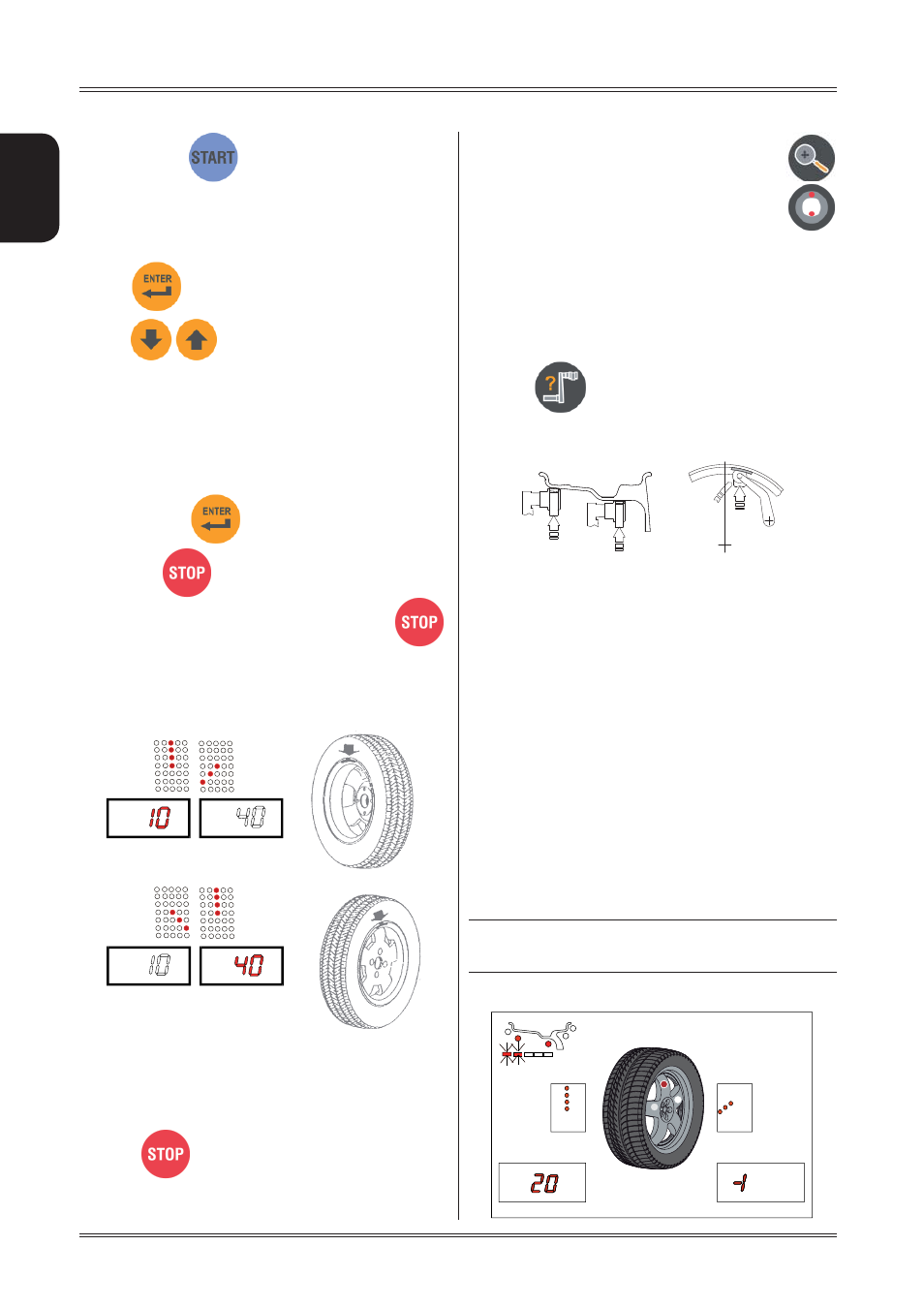

5.1.1 Modifying set dimensions

If the wheel dimensions have been entered incorrectly,

the parameters can be modified without repeating the

balancing spin by pressing for 2 seconds :

access parameter modifi cation

→

(select

to modify: (a) distance, (b) width, (d)

diameter

In the case of standard weights:

(a)distance,(b)width,(d)diameter

In the case of adhesive weights:

(a1) inside distance,(a2) outside distance,(d1) inside

diameter,(d2) outside diameter

press

to select (a) (b) or (d)

→

to recalculate the unbalance

or:

pull out the gauge to repeat the measurement

→

to obtain the new measurement.

5.2 MEASUREMENT

RESULT

Move the wheel manually until all the LED’s correspond-

ing to the side light up. The display shows the measured

unbalance. If the wheel clamp option is enabled (see

MENU

), the wheel is automatically clamped in the correc-

tion position.

Pressing

the chuck can be locked/released in any

position to facilitate mounting the wheel (see

MENU

).

For unbalance within tolerance 0 (zero); using

values within tolerance can be viewed.

If the static unbalance is greater than 30 g, the LED

fl ashes to suggest an unbalance optimisation operation

(see

UNBALANCE OPTIMISATION

).

5.3 EXACT POSITIONING OF THE ADHESIVE

WEIGHT BY MEANS OF THE GAUGE WITH

CLIPS

P

▪

ress

if using the correction method with

adhesive weights on the inside of the rim

Fit the correction weight in the specific gauge seat with

▪

the adhesive part facing upwards

Bring the wheel into correct angular position for the

▪

plane to be corrected

If the wheel clamp option is enabled (see

▪

MENU

),the wheel

is automatically clamped in the correction position.

Pull out the gauge up to the distance set

▪

(see

WHEEL

DIMENSIONS PRESETTING

b/c)

If the buzzer is enabled (see

▪

MENU

), the attainment

of the weight application distance is accompanied by

a beep.

Using the special weight pusher, rotate the gauge until

▪

the correction weight adheres to the rim.

If gauge locking is enabled (see

▪

MENU

), the gauge is

automatically locked when the weight application distance

is reached. To release the gauge, lower it to below 10”

diameter

the fact that the weight application position is no longer

▪

vertical is automatically compensated.

INDICATION

The approach of the weights to the correction positions

is indicated by the LEDs number 19

► Inside

Use of the wheel balancer