C.E. Niehoff & Co. N1610-1 Installation User Manual

Installation instructions

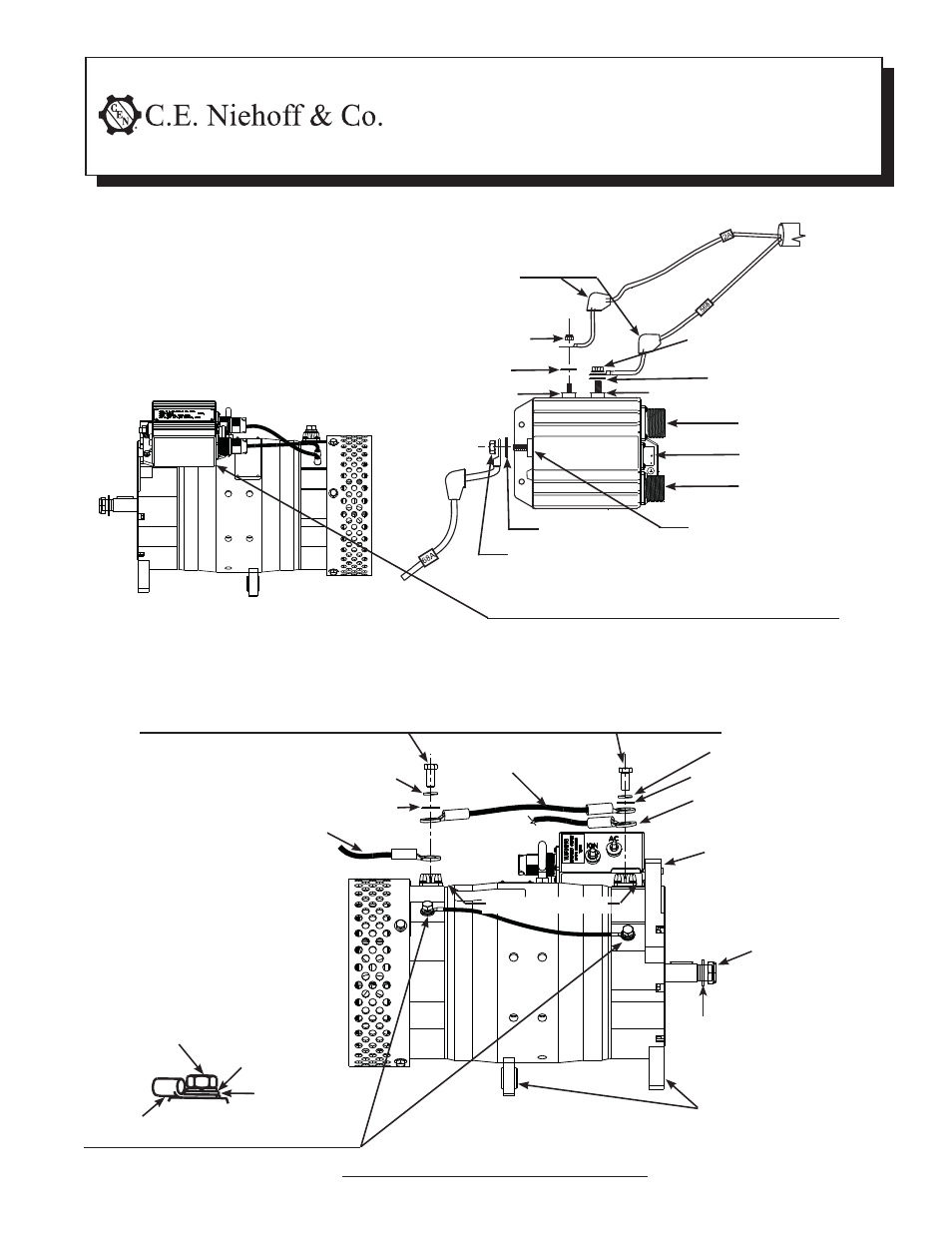

Boots (2)

II0160A

Page 1 of 2

N1610-1 Alternator / N3247 Regulator

Installation Instructions

28/14 V or 28 V

Wiring Connections

Locknut, 0.250-20;

torque to 3.4 Nm / 30 lb.in.

Washer

Regulator - AC terminal

Vehicle

harness

Regulator - IGN terminal

28/14 V applications

(see other side for 28 V):

Connect as shown on this page.

Figure 1a - N3247 Regulator Wiring Connections

Figure 1- N1610-1 Alternator

Lock washer

Figure 1b - B+ and B– Terminal Connections

AC connector

Locknut, #10-24;

torque to 3.4 Nm / 30 lb.in.

Washer

B+ connections on alternator

Bolt, 0.3750-16 UNC-2A; torque to 20 Nm / 15 lb.ft. when securing positive cable of suitable size for output power. Both

positive cables must be connected together at battery positive potential when alternator is installed in vehicle and during

operation. Cable as shown must be used as part of vehicle cabling.

Washer

Interconnect

cable

Positive cable from vehicle

B+ output terminals

Lock washer

Washer

Positive cable

from vehicle

B– connections on alternator

Bolt, 0.3125-18 UNC-2A; torque to

9 Nm/80 lb. in. when securing B– cable

of suitable size for output power. Both

ground cables must be connected to

vehicle’s common ground using inter-

connect cable B– plus cable of suitable

size as part of vehicle cabling when

alternator is installed in vehicle and

during operation.

Secure alternator mounting

lug to vehicle using hardware

specifi ed by vehicle manufac-

turer and torque suffi cient to

withstand weight of alternator.

Secure alternator mounting

lugs to vehicle using hardware

specifi ed by vehicle manufac-

turer and torque suffi cient to

withstand weight of alternator.

Vehicle

harness

Lock Washer

Washer

MS21245-L12 nut;

torque to 163 Nm/

120 lb. ft. when

installing drive pulley.

Washer

Boot

Washer

Nut, 0.312-18 UNC-2B;

torque to 5.6 Nm / 50 lb.in.

Regulator - 14 V terminal

J1939 connector

Alternator connector