C.E. Niehoff & Co. N1381: N7300 Replacement Kit Instructions User Manual

N1381 alternator, C. e. niehoff & co, Conversion instructions

Page 1

II0068A

N1381 Alternator

Conversion Instructions

C. E. Niehoff & Co.

BRUSHLESS ALTERNATORS

Using N7300 Conversion Kit

The following term is used to bring attention to the presence of hazards of various risk levels or to important information con-

cerning product life.

Indicates the presence of hazards that will cause severe personal injury, death, or substantial

property damage if ignored.

DANGER

DANGER

Disassembly

1. Disconnect B+ cables from inside the control

unit.

2. Unsolder resistor wires from modules.

3. Remove potting from control unit.

4. Remove screws holding control unit assembly to

housing.

5. Remove and discard control unit assembly.

6. Clean old potting from inside control unit.

Assembly

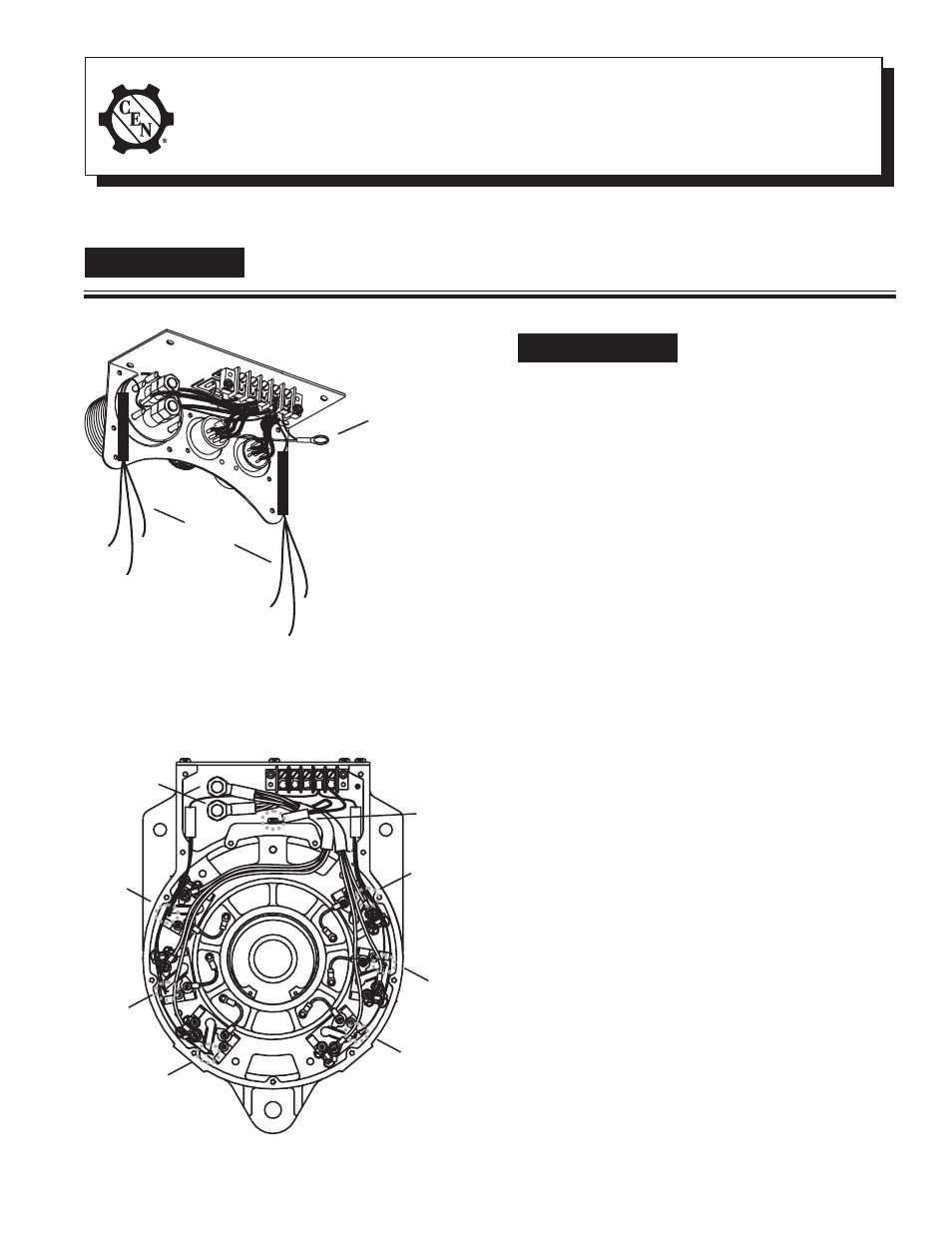

1. Attach new control unit assembly (see Figure 1)

to housing. Use suitable adhesive, such as

Loctite® 222. Follow manufacturer’s instruc-

tions. Torque new hardware to 5 Nm/45 lb. in.

2. Connect B+ cables inside the control unit.

Torque hardware to 15 Nm/135 lb. in.

3. Using hardware provided in kit, attach ground

terminal lead from control unit terminal strip to

threaded hole in top of casting. See Figure 2.

Torque new hardware to 5 Nm/45 lb. in.

4. Using standard solder, connect the six resistor

leads to the points shown in Figure 2.

Figure 1—New Control Unit Assembly

T T T T T

Ground

terminal lead

T T T T T

Resistor

leads

TTTTT

Do not allow hardware to drop

inside alternator. Loose hard-

ware inside alternator cavity or

stator windings or field coil

will cause substantial

equipment damage.

Resistor

lead

TTTTT

Ground

terminal

lead

T T T T T

Resistor

lead

TTTTT

Resistor

lead

TTTTT

Resistor

lead

T T T T T

Resistor

lead

T T T T T

Resistor

lead

T T T T T

Figure 2—Drive End (DE) Housing Connections

B+

cables

TTTTT

TTTTT