C.E. Niehoff & Co. N1126-1 Alternator Installation User Manual

C. e. niehoff & co

N1126-1 Alternator/N3034 Regulator

OEM Wiring Connections

Installation Instructions

C. E. Niehoff & Co.

BRUSHLESS ALTERNATORS

This symbol is used to indicate

presence of hazards that can cause

minor property damage.

CAUTION

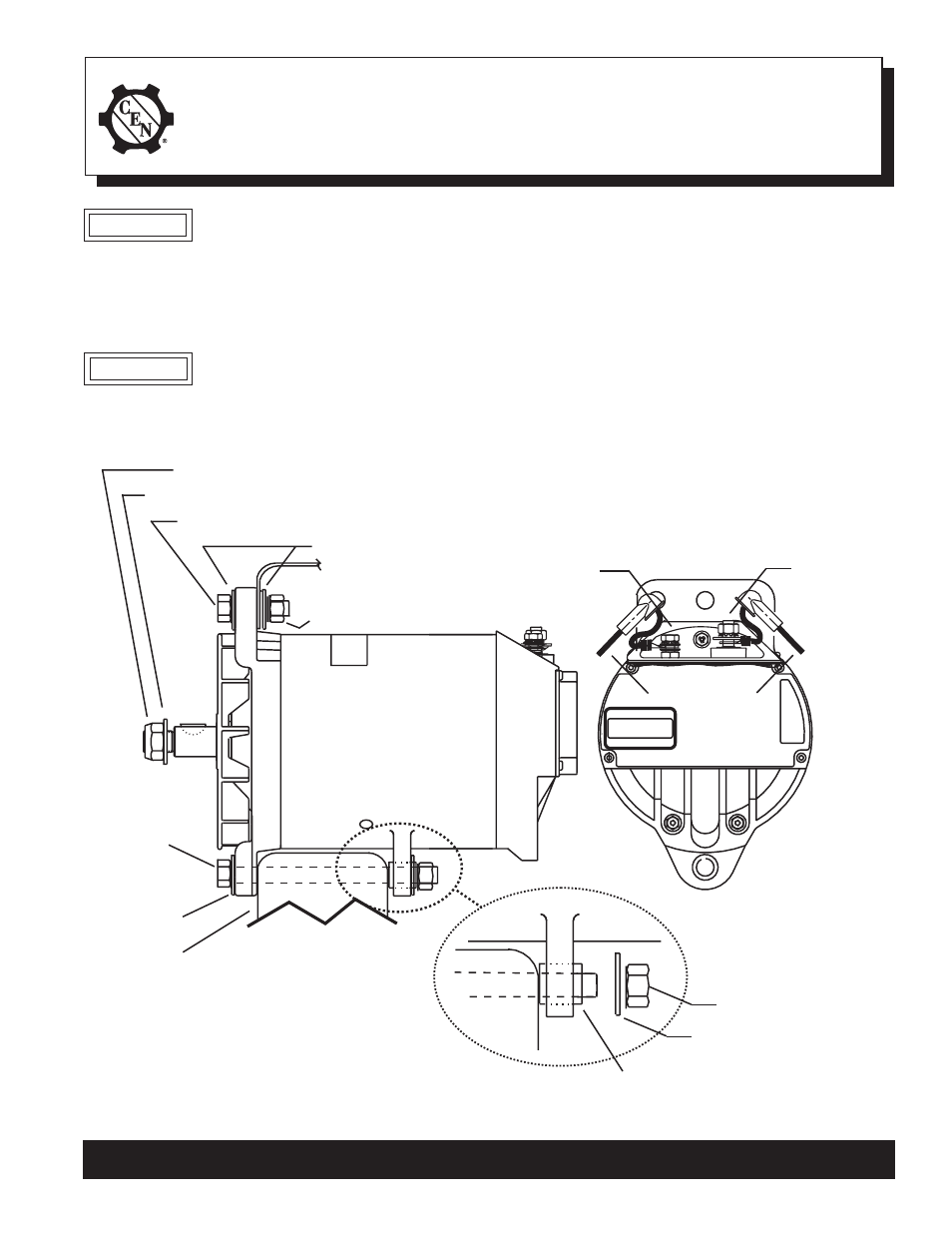

Install N1126-1 alternator as shown in Figure 1:

Slip bushing located in rear mounting

foot must be securely tightened against

alternator mounting bracket on engine. Failure to do so

can result in broken mounting feet or broken upper

mounting bracket.

Figure 1 - N1126-1 Alternator Installation Details

CAUTION

1. Units are shipped with shaft collar, hardened

washer and locknut. Remove and discard shaft

collar. Install pulley and furnished hardened

washer. Torque locknut to 136 Nm/ 100 lb. ft.

2. Use hardened washers between aluminum surfaces

and bolt heads and nuts. Torque mounting bolts to

80 Nm/60 lb. ft.

3. All cabling, wiring or conduit must be supported

within 305 mm/12 in. of termination on alternator.

4. Choose wire gauge for B+ and B– cables capable of

handling maximum alternator output with minimum

voltage drop.

B+ terminal

0.3125-18 locknut –

torque to

9 Nm/80 lb. in.

T T T T T

B– terminal

0.25-20 locknut –

torque to 9 Nm/80 lb. in.

T

T

T

T

T

12mm/0.50 Locknut –

torque to

80 Nm/60 lb. ft.

T T T T T

Hardened washer

T T T T T

Slip bushing must be tightened against

bracket — see “CAUTION” above

T T T T T

0.625 - 18 Locknut

torque to 136 Nm/100 lb.ft.

T T T T T

T T T T T

Hardened washer

12mm/0.50 in.

mounting bolt

(full length)

TTTTT

Hardened

washer

TTTTT

Bracket

on engine

Alternator

mounting

bracket

on engine

TTTTT

T T T T T

12mm/0.50 in. Mounting bolt

Hardened washers

T T T T T

12mm/0.50 Locknut –

torque to 80 Nm/60 lb. ft.

TTTTT

T

T

T

T

T

T

T

T

T

T

T T T T T

Customer cables

w/terminal boots

II0060A

Page 1 of 1

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633