C.E. Niehoff & Co. C803D/C840D Alternator Retrofit/Upgrade Installation User Manual

Retrofit/upgrade installation instructions, Ii65g page 1 of 2

Retrofit/Upgrade Installation Instructions

C803D and C840D

Alternators

This symbol is used to indicate the presence

of hazards that can cause minor personal

injury or property damage.

CAUTION

* Use this setpoint to maintain proper battery charge level during

shorter operating cycles.

Table 1 — A2-330/A2-336 Regulator Voltage Selector Switch Position

Switch Position

Battery Type

1

27.5 V

Maintenance

2

28.0 V

Maintenance*

3

28.5 V

Maintenance-Free

4

29.0 V

Maintenance-Free*

If an extended wiring harness is supplied with

alternator and regulator, see separate instruc-

tions packed with harness.

This symbol is used to indicate the presence

of hazards that can cause severe personal

injury or substantial property damage.

WARNING

Table 2 — A2-346 Regulator Voltage/Battery Switch Position

Switch

Position

A9-4036 Harness

Not Connected

(Voltage Select)

A9-4036 Harness

Connected (Battery Select)

1

27.5 V

Maintenance (D Catergory)

2

28.0 V

Maintenance-free (Group 31)

3

28.5 V

AGM

4

29.0 V

DO NOT USE POSITION # 4

A2-346 regulator is flat-temperature compensated.

A2-346 28 V regulator can be used with or with-

out A9-4036 temperature-voltage sense/J1939

harness from the vehicle.

• When A9-4036 temperature-voltage sense/

J1939 harness is not connected, regulator will

operate in fixed voltage setting determined

by the select switch position on the bottom of

the regulator. See column 2 in Table 2.

• When A9-4036 temperature-voltage sense/

J1939 harness is connected, regulator will

automatically optimize the charge voltage for

battery type based on temperature. See col-

umn 3 in Table 2 and select switch position

based on battery type.

Regulator is factory-set to Position 1. To change, remove regu-

lator, turn regulator over, and select appropriate switch

position (see NOTICE above and Table 2). Re-install regulator

on alternator. Torque screws to 8.5 Nm/75 lb in.

NOTICE

This symbol is used to indicate special instruc-

tions on installation, operation, or maintenance

that are important, but not related to per-

sonal injury hazards.

NOTICE

II65G

Page 1 of 2

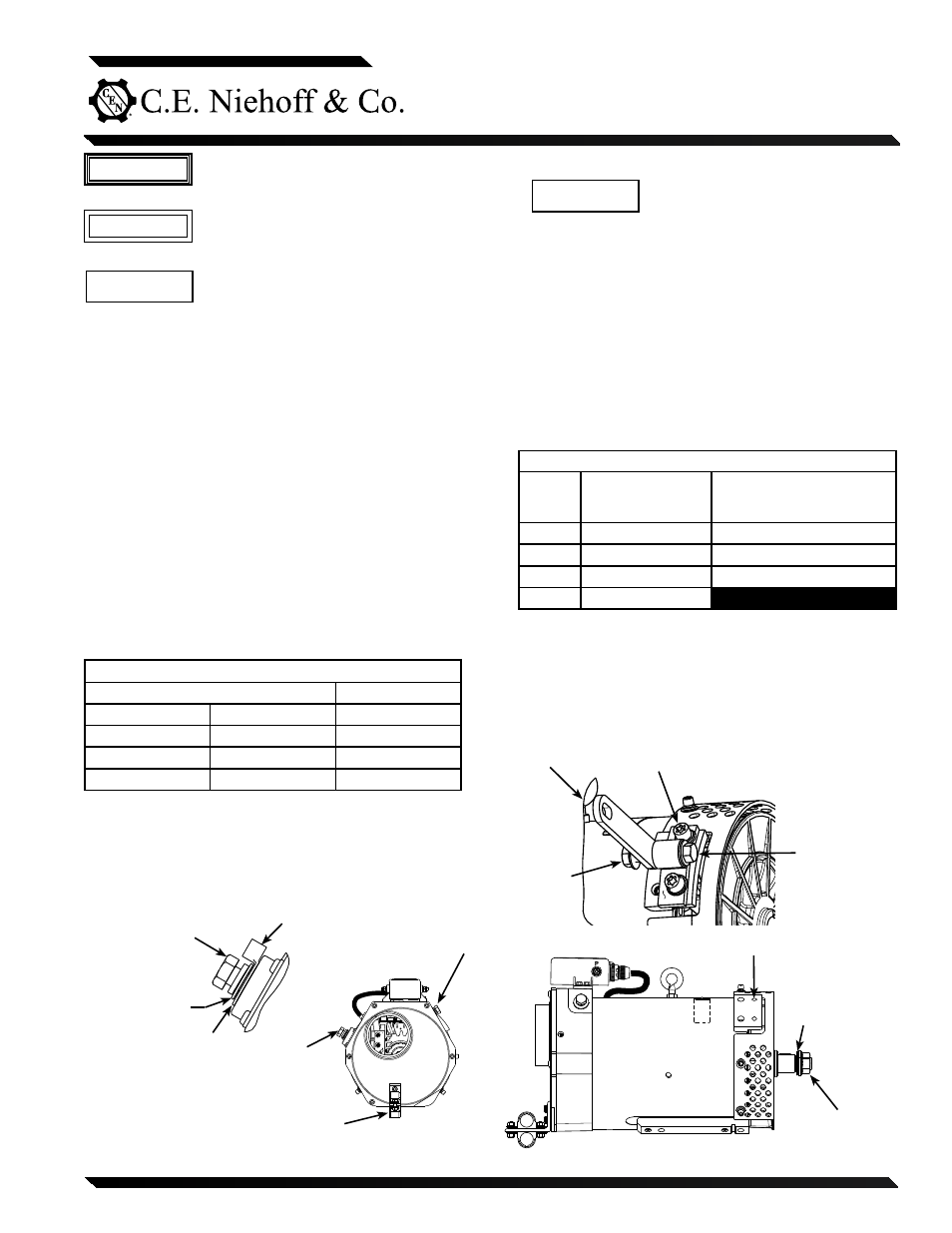

Figure 1 - Alternator Installation Details

B+ terminal –

see inset above

B– terminal M10 bolt –

torque to 15 Nm/11 lb. ft.

M20 nut–torque to

163 Nm/120 lb. ft.

Disc spring

washer

B+ terminal M12 bolt –

torque to 30 Nm/22 lb. ft.

Battery output

cable terminal

Washer

Lock washer

Dampening bracket mount –

see inset above

Non-louvered duct opening to attach

fresh air intake pipe. See Step 7, page 2.

M10 x 1.5 bolt, lockwasher, washer: 2 places –

torque to 27 Nm/20 lb. ft.

Secure to

engine block

(see step 2c above)

Bolt and washer

torque to

57 Nm/42 lb. ft.

Nut

1. Turn off battery switch or disconnect battery ground cable.

2. Remove alternator drive belt.

3. Remove all oil lines between alternator and engine. Plug oil

line outlets with properly-sized pipe or tubing plugs. Remove

oil drain hose at existing alternator and plug opening.

4. Label wires for identification, then disconnect electrical con-

nections from existing alternator.

5. Remove alternator mounting bolts and existing alternator

from mounting bracket.

6.

A2-330/A2-336 regulators are flat-temperature compensated

and are factory-set at lowest setting to accommodate 8D

batteries. For other batteries:

a. Remove regulator from housing and change position on

voltage selector switch. See Table 1.

b. Re-install regulator on drive end housing, and torque

mounting screws to 8.5 Nm/75 lb. in.

7. Units are shipped with shaft collar, Belleville washer and

nut. Remove and discard shaft collar. Install pulley and

furnished Belleville washer. Torque nut to 162.7 Nm/

120 lb. ft.