C.E. Niehoff & Co. C672 Alternator Installation User Manual

C672 alternator, Installation instructions

II211A

Page 1 of 1

C672 Alternator

Installation Instructions

This symbol is used to indicate presence

of hazards that can cause minor property

damage.

CAUTION

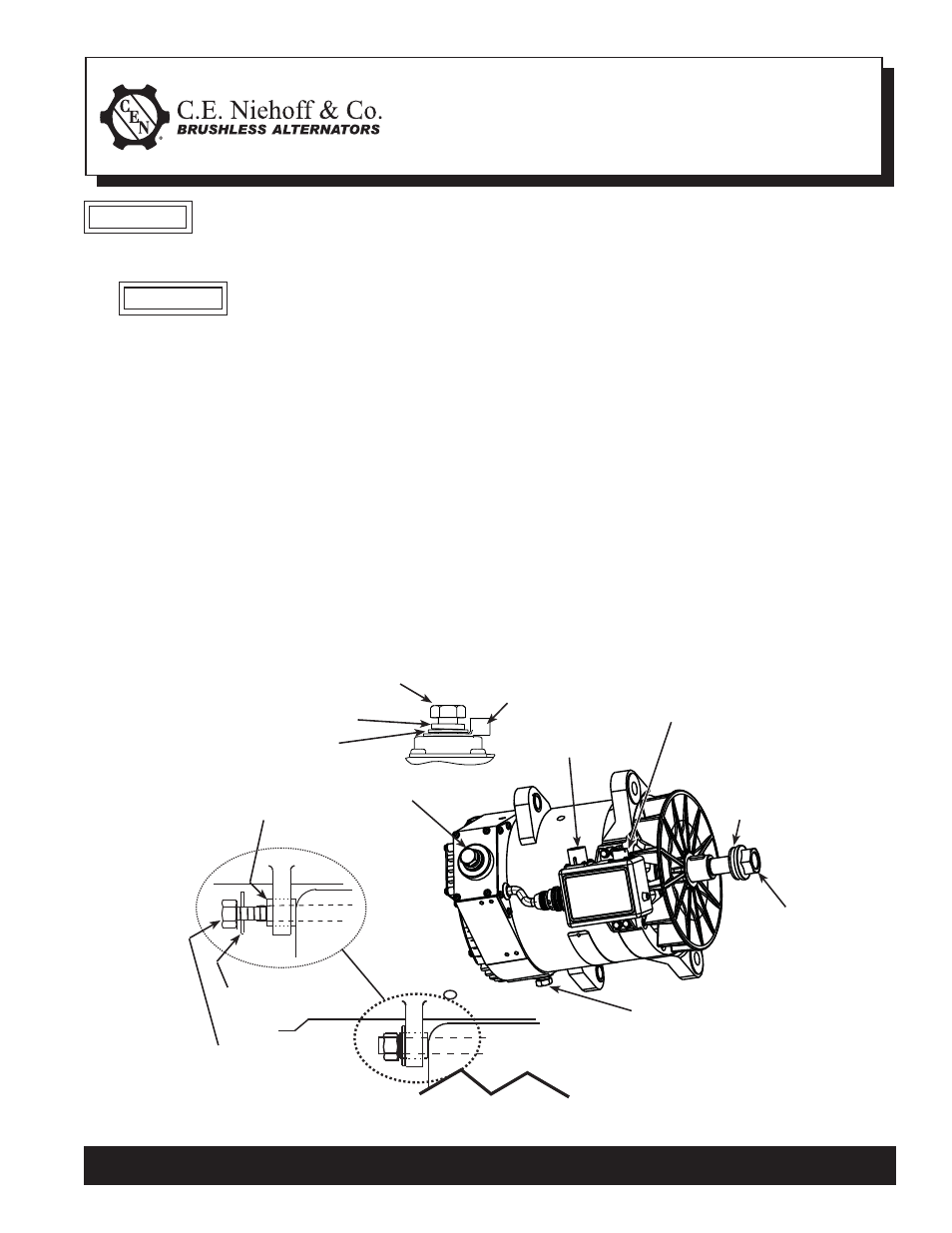

1. Install alternator as shown in Figure 1:

Slip bushings located in front and

rear mounting lugs must be

securely tightened against alter-

nator mounting bracket on engine.

Failure to do so can result in

broken mounting lugs or broken

mounting

bracket.

a. Use hardened washers between aluminum

surfaces and bolt heads and nuts. Bolts to be

SAE grade 5 min., metric class 8.8 min.

b. OEM units are shipped with pulley, disc spring

washer and locknut installed.

c. Aftermarket units are shipped with shaft collar,

disc spring washer, and nut. Remove and dis-

card shaft collar. Install pulley and furnished

disc spring washer. Torque nut to 163 Nm/

120 lb. ft.

d. Follow vehicle manufacturer’s recommendations

for belt tension.

Figure 1 - C672 Alternator Installation Details

CAUTION

Hardened washer

2. All cabling, wiring or conduit must be supported

within 305 mm/12 in. of termination on alternator.

3. Choose wire gauge capable of handling maximum

alternator output with no more than 0.4 V drop on

each leg from alternator to battery.

4. Regulator is furnished with OEM units and is sup-

plied separately by request with aftermarket units.

Mounting screws on regulator should be torqued to

8.5 Nm/75 lb. in.

5. Make electrical connections to CEN regulator as

required, using proper ring terminals (follow vehicle

manufacturer’s diagram and separate instructions

packed with extended wiring harness when used):

a. Make sure alternator-to-regulator harness

is plugged securely in regulator receptacle.

b. A2-342 regulator furnished with some units

has

additional:

• 3-pin connector for D+/Phase/Eng

connection to vehicle

• J1939 connector to vehicle

Securely attach appropriate vehicle cables to

these connectors as required.

M16/0.63 bolt and washer –

torque to 108 Nm/80 lb. ft.

Slip bushings in front and rear mounting

lugs must be tightened against bracket —

see “CAUTION” above

Bracket

on engine

Alternator B

– M10x1.5 bolt,

lockwasher and washer—

torque to 15 Nm/11 lb. ft.

B+ terminal –

see inset above

B+ terminal M12 x 1.75 bolt –

torque to 30 Nm/22 lb. ft.

Battery output

cable terminal

Washer

Lock washer

M20 nut–torque to

163 Nm/120 lb. ft.

Disc spring

washer

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

3-pin

connector

J1939

connector