C.E. Niehoff & Co. C540 Alternator Installation User Manual

Page 2

II176A

Page 2 of 2

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

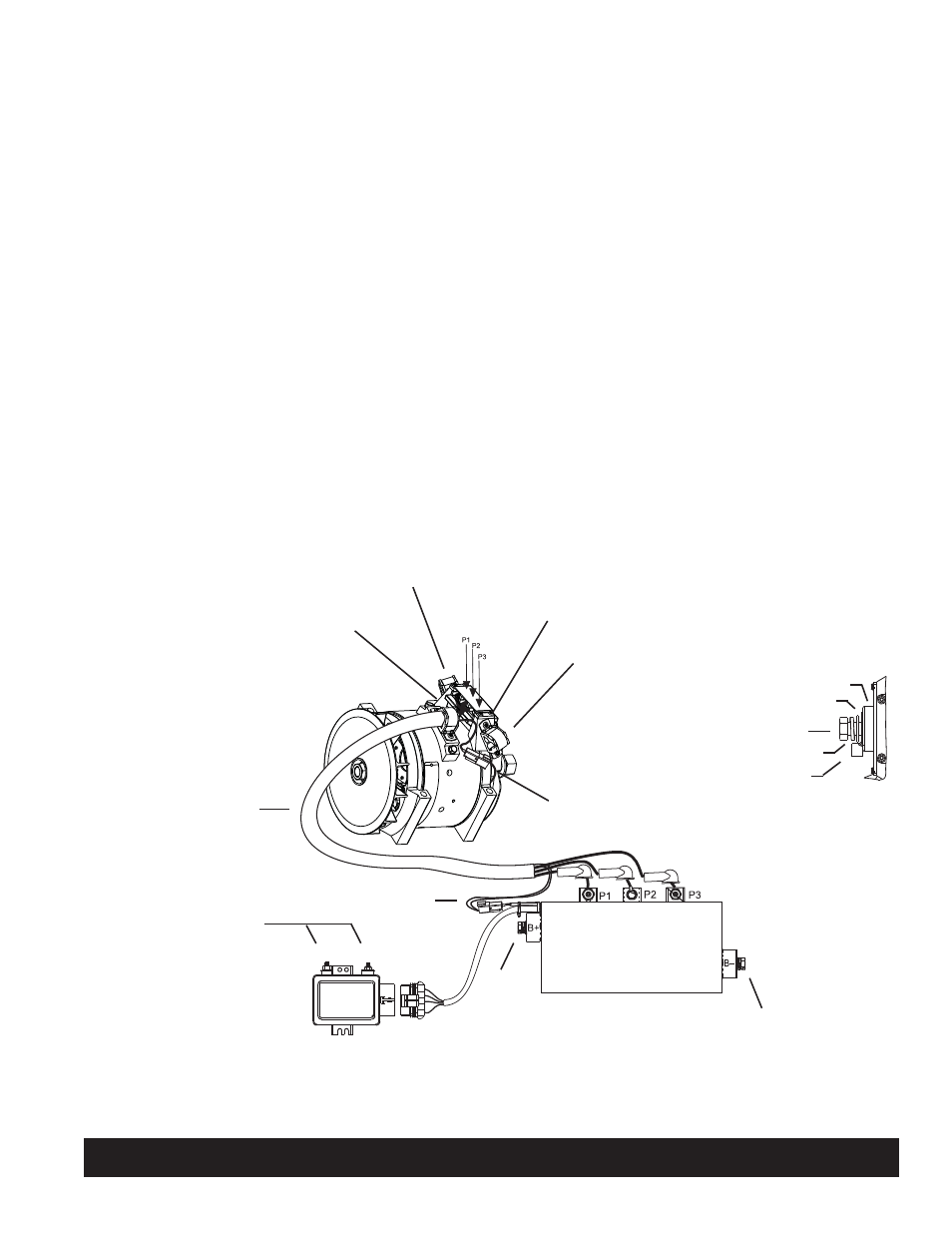

Figure 4 - Electrical Connections

P

IGN

B+ terminal bolt –

torque to 30 Nm/22 lb. ft.

Battery output cable terminal

Washer

Lockwasher

Insulator

B– terminal bolt –

torque to 30 Nm/22 lb. ft.

Screws –

torque to 6.7 Nm/60 lb. in.

P and IGN

terminal nuts –

torque to

3.4 Nm/30 lb. in.

Field inline connection

Field

inline

connection

B+

(see

inset above)

B+ Terminal Connection

Phase terminal bolts (3 places) –

torque to 8 Nm/70 lb. in.

Cable bracket

LOC. A

Cable bracket

LOC. B

Phase

cable

Wiring Connections

1. Connect alternator phase cable into terminal

block on top of alternator:

a) Run phase cable through cable bracket

mounted in one of three locations (LOC. A, B,

or C). See Figure 4.

b) Torque screws to 9 Nm/80 lb. in. to fasten

cables to terminal block.

c) Coat terminals with Dow Corning®1-2577

Low VOC RTV coating or equivalent. Do not

use coating containing acetic acid (vinegar

smell) on electrical components.

2. Connect remaining harnesses between compo-

nents as shown in Figure 4. Use torque values

shown.

3. Choose wire gauge for B+ and B– cables capable

of handling maximum alternator output with

minimum voltage drop.

4. Connect IGN terminal on regulator to ignition

source through oil pressure switch, using #10

ring terminal. Torque #10-24 terminal nut to

3.4 Nm/30 lb. in.

5. If required, connect P terminal to tachometer or

relay, using 1/4 in. ring terminal. Torque termi-

nal nut to 3.4 Nm/30 lb.in.

Sealing Wiring Connections

1. On ALL metallic electrical connections to rectifier

(including B+ and B– connections), alternator,

regulator, and their harness connectors, apply

Dow Corning® 1-2577 Low VOC RTV coating or

equivalent. Do not use coating containing acetic

acid (vinegar smell) on electrical components.

2. At regulator harness connections, apply coating as

described in step 1, then wrap connection in

electrical tape from sleeve to sleeve.

Cable bracket

LOC. C