C.E. Niehoff & Co. C510 Alternator Installation User Manual

Page 2

II0039A

Page 2 of 2

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Regulator

1. Mounting location of regulator must provide

protection from water, road debris, or

chemicals.

Regulator can be located up to 18 inches

away from the rectifier. If extension harness

CEN A9-448 is added, the regulator can be

moved an additional 43 in. away.

2. See Figure 3 for torque values.

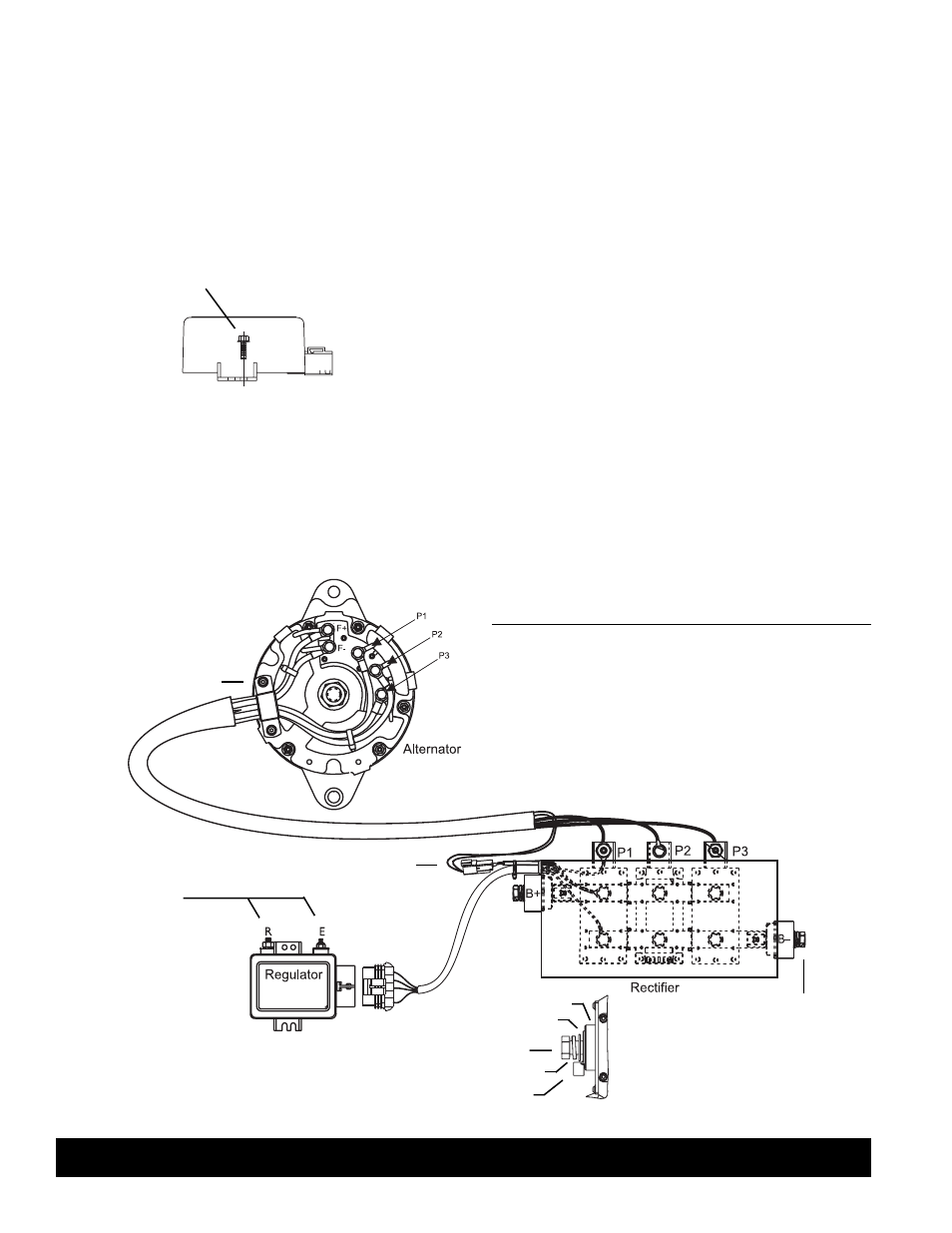

Figure 3 - Regulator Installation

#10-32 x .62 flange lock screw (4 places) -

torque to 8.5 Nm/75 lb. in.

Wiring Connections

1. Connect harnesses between components as

shown in Figure 4. Use torque values shown.

When operating with a battery isolator, field

positive (F+) must be connected to battery

positive (B+).

Figure 4 - Electrical Connections

B+ terminal bolt –

torque to 30 Nm/22 lb. ft.

Battery output cable terminal

Washer

Lockwasher

Insulator

B– terminal bolt –

torque to 30 Nm/22 lb. ft.

P1, P2, P3 phase terminal bolts –

torque to 8 Nm/70 lb. in.

Terminal bolts (5 places) –

torque to 4.5 Nm/40 lb. in.

Screw –

torque to 9 Nm/80 lb. in.

R and E

terminal nuts –

torque to

3.4 Nm/30 lb. in.

Field inline connection

1 Loctite is a registered trademark of Loctite Corporation.

2 Dow Corning is a registered trademark of the Dow Corning

Corporation.

2

Choose wire gauge for B+ and B– cables capable

of handling maximum alternator output with

minimum voltage drop.

3. All output leads must be supported within

305 mm/12 in. of termination and cabling,

wiring or conduit run supported at 406.0mm/

16 in maximum intervals. Strain relief must be

provided and cable ties used.

4. Connect E terminal on regulator to ignition

source through oil pressure switch, using #10

ring terminal. Torque #10-32 terminal nut to

3.4 Nm/30 lb. in.

5. Connect R terminal to tachometer or relay, using

1/4 in. ring terminal. Torque terminal nut to 3.4

Nm/30 lb.in.

Sealing Wiring Connections

1. On ALL metallic electrical connections to

rectifier (including B+ and B– connections),

alternator, regulator, and their harness connec-

tors, apply Dow Corning

®2

1-2577 Low VOC

RTV coating or equivalent. Do not use coating

containing acetic acid (vinegar smell) on electri-

cal components.

2. At regulator harness connections, apply coating

as described in step 1, then wrap connection in

electrical tape from sleeve to sleeve.