Introduction, How a servo feed operates – PA Industries MINI Servo Roll Feed SRF-105M through SRF-320 User Manual

Page 3

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

3

1. INTRODUCTION

The P/A Industries Mini Servo Roll Feed is a state of the art AC Servo feed, which eases operator adjustments to feed

pitch, speed, and acceleration. These operator adjustments are entered into the control memory by keypad input. With

the use of a positional limit switch, the press signals the feeder when to begin moving the strip. The operating speed of

the press should be set to provide adequate time for the index to be completed while the die is open.

The mechanical simplicity, accuracy, and ease of use of the Mini Servo Roll Feed should help to improve your quality

and production for years to come.

2. HOW A SERVO FEED OPERATES

The Mini Servo Roll Feed consists of:

1)

Mechanical

assembly

2)

Servomotor

3)

Servo

Control

The servo control acts as the central processor for the Mini Servo Roll Feed. Feed parameters entered into the servo

control are processed to position the servomotor. Calibration of the motor encoder to the feed roll circumference

allows accurate positioning of the feed roll. Each revolution of the servomotor produces 8000 encoder pulses. Every

2.857 revolutions of the servo motor shaft produce 1 revolution of the feed rollers. The circumference of the lower roll

is approximately 5.566 inches.

When a new feed pitch is entered into the system, the built-in computer calculates the correct number of electronic

“pulses” it must receive from the motor mounted encoder in order to rotate the feed rolls the correct distance.

Example: If a feed pitch/length of 5.566 inches is entered into the feeder, this will result in exactly one revolution of

the feed rolls. The motor will accelerate and turn 2.857 turns. This will produce (2.857 x 8000 = 22,856) pulses of

the encoder. The feeder will decelerate and stop when 22,856 pulses are detected. The feeder is now on position. The

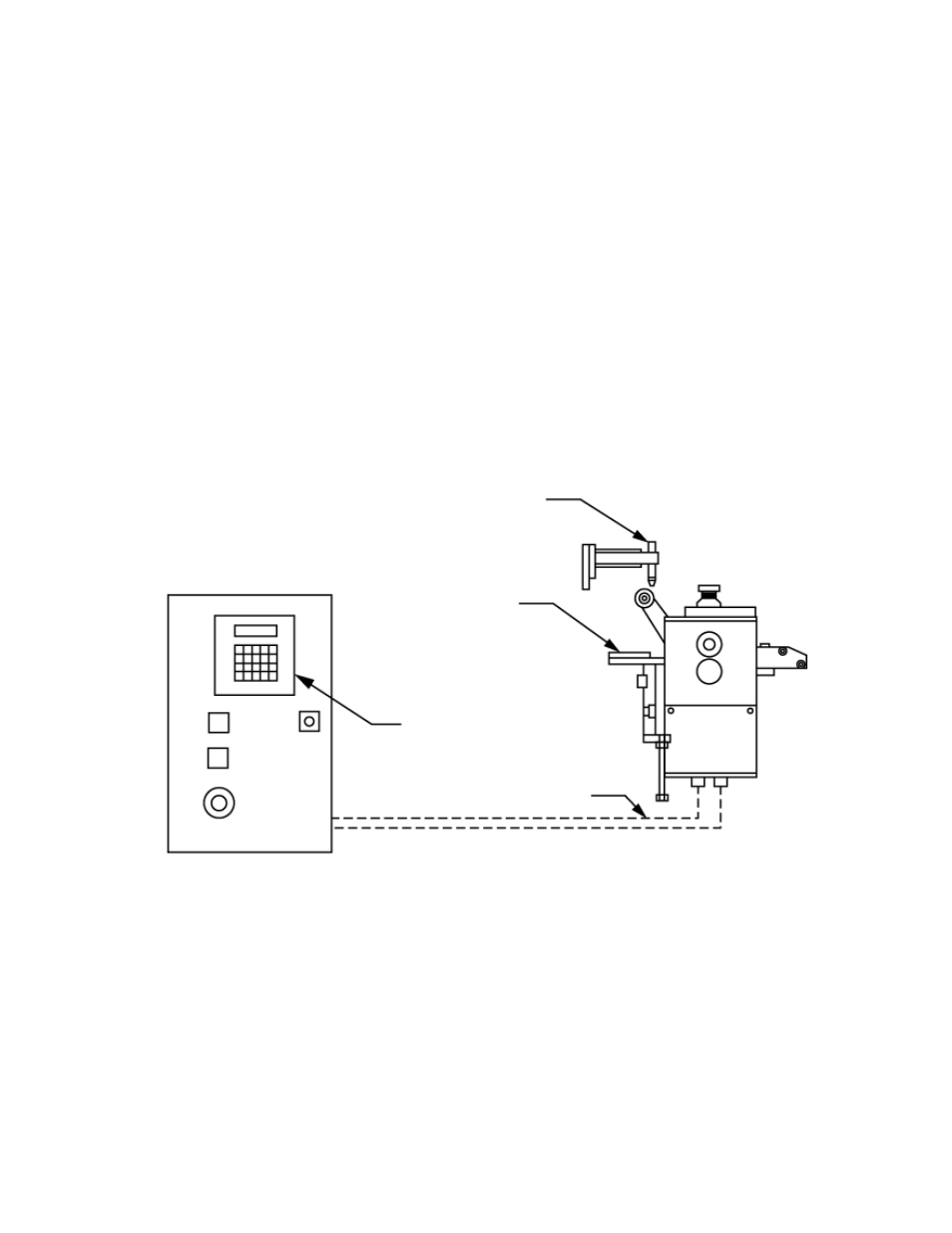

MECHANICAL PILOT

RELEASE ACTUATOR

CONTROL

ENCLOSURE

ADJUSTABLE

MOUNTING

BRACKET

DATA

TERMINAL

CABLES

Figure 1