PA Industries MINI Servo Roll Feed SRF-105M through SRF-320 User Manual

Page 11

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

11

NOTES ABOUT "POSSIBLE PROBLEM TOOLING"

•

A tight die, one that is not square, or has other tooling problems, will cause significant difficulty and

downtime. Accuracy in feeding is directly related to how easily the feeder can position the strip in the die. Binding,

bad part ejection, or sticking parts may cause the material to “jam” in the die.

•

The Mini Servo Roll Feed will “try” to overcome the "jam-up" by applying more power to the rolls.

ONE OF THREE OUTCOMES WILL RESULT:

•

The feed will apply more power to the rolls causing them to slip on the material. This produces a “short-feed”.

In reality, the feeder did not “misfeed”. The rolls positioned properly; the strip just did not keep up. The die then closes

producing a miss-hit.

•

The feed applies more power to a thin strip causing the material to buckle somewhere between the feed and the

die set. The feeder positioned the strip accurately, it just did not occur in the die set.

•

The feed tries to apply so much power to a heavy strip in order to move it, that excessive current is drawn by

the servo drive. This results in the drive shutting itself down to protect itself.

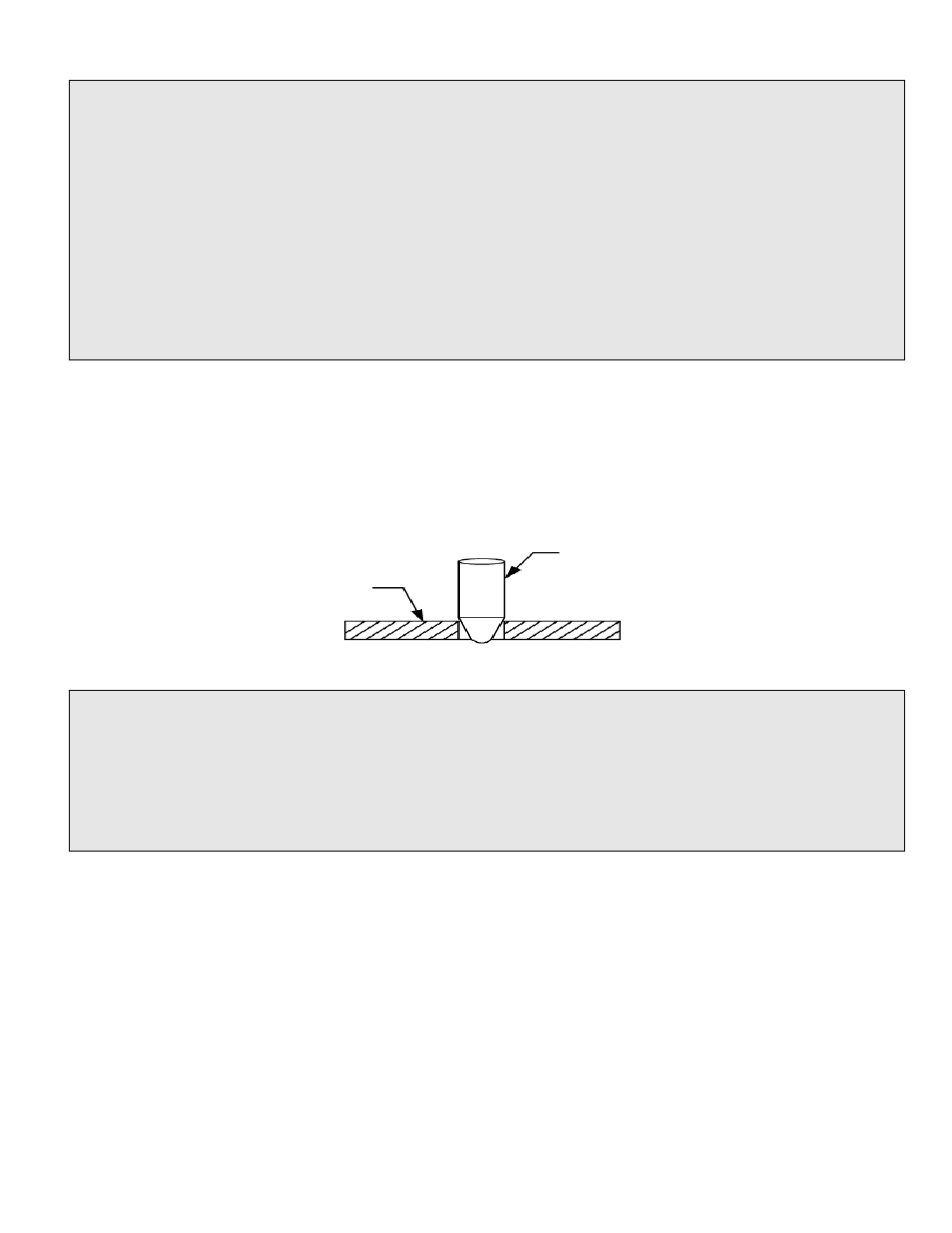

The press ram should now be “inched” down until the pilot pin is located just above the prepunched strip. The

mechanical pilot actuator on the feed should now be adjusted to open the rolls just after the pin is into the strip. (See

Figure 4.)

The ram can now be inched thru the bottom of the stroke and carefully inched up until the pilot pin or longest punch is

just clear of the strip.

Now look at the entire die set and see that it is "safe" to move the strip. If so, now is the time to set the ‘Feed

Index Cam’.

S T R IP

P IL O T P IN

Figure 4

NOTE ABOUT CAMS:

The Feed Index Cam (open tool): The feed system uses this press cam for timing the feeder to the press crankshaft.

Although no shafting or belts actually connect the press to the feeder, the feed must be “told” when it is safe to move

the strip.

•

This “connection” is an electrical one, and not a mechanical one. This gives the operator/set-up personnel

total flexibility in deciding when the feed progression should take place.

•

Each die set can have a unique ‘Feed Angle’. This ‘Feed Angle’ is dependent upon many variables; pilot and

punch length, press stroke, strip forming in the die, etc.