Operating the feed – PA Industries MINI Servo Roll Feed SRF-105M through SRF-320 User Manual

Page 10

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

10

5. OPERATING THE FEED

NOTE:

It is very important to remember that the motor on The Mini Servo Roll Feed System is only for feeding material. It is

not intended to be the power source for a pull-through straightening device, or the like. An adequate free loop must be

provided at all times. This will assure consistent and accurate feeding.

5.1 LOADING

THE

FEED

The material should be brought from the powered pay off device to the feeder. The rolls of the feed must now be

opened to accept the material. This is done by roll release lever to lift the upper roll. The maximum thickness

capability of the Mini Servo Roll Feed is .062 inches. Do not try to operate the feeder with material that is thicker than

it was designed to feed. Damage to the feeder may result.

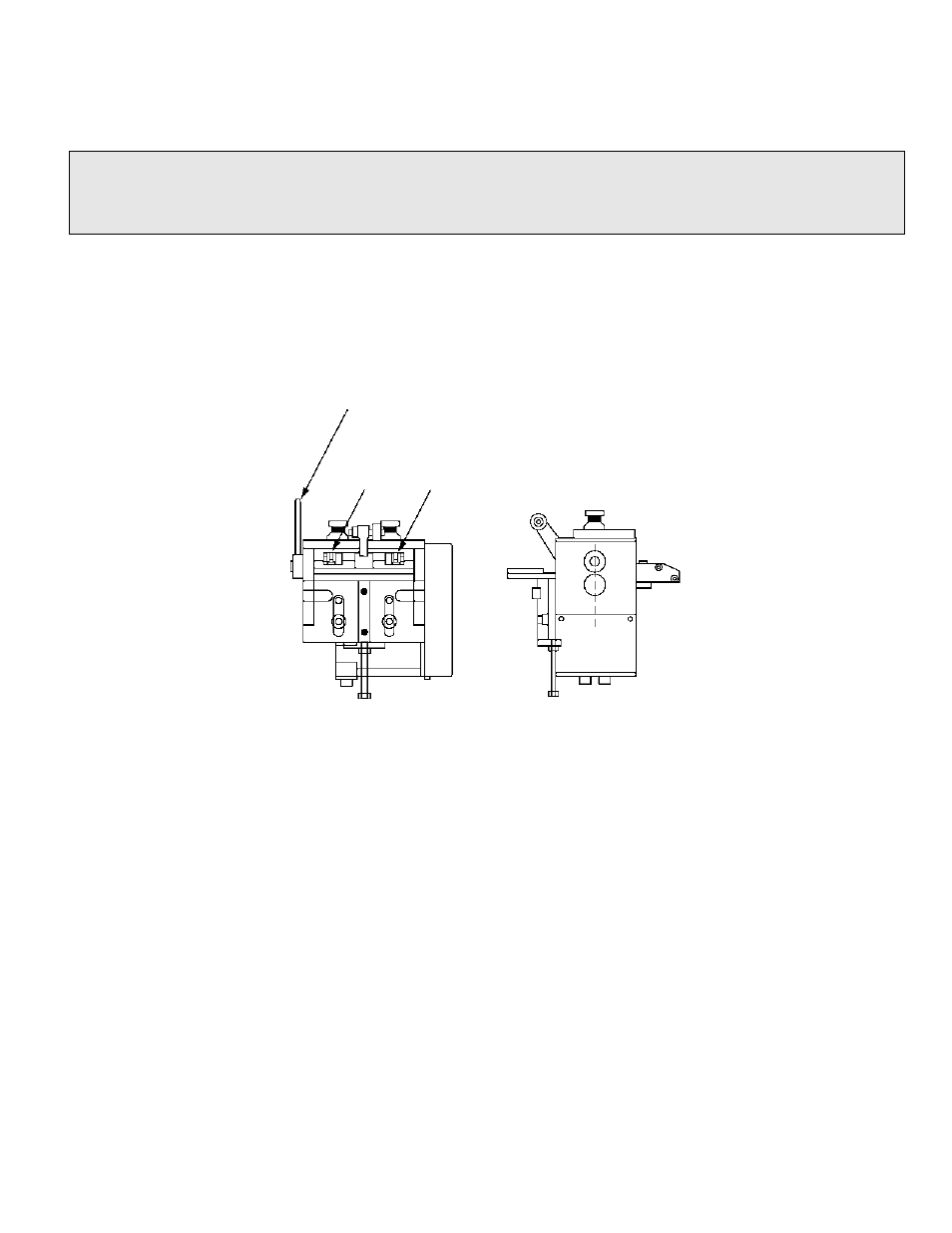

ROLL RELEASE LEVER

MATERIAL THICKNESS ADJUSTMENT

Figure 3

With the material inserted into the feed rolls and the upper roll resting on the material, the two socket head thickness

screws should be adjusted to provide minimum “play” in the pilot release actuator arm. Tighten the lock nuts.

We presume that the feed system has been programmed with the proper Length, Speed, and Accel for the first die set.

Also, that the press has been adjusted for the current job (i.e. shut height, tonnage monitors, lubrication, speed, etc.).

The material should be jogged into position at the die set (first station on a progressive type die). Check the “free

running” of the strip in the die.

If possible, put the strip through the entire die set, open the rolls, and make sure the material slides easily in the die set.

Once the material is aligned square into the die, then the guide rollers on the inlet of the feeder must be adjusted.

These rollers should be locked into position with approximately .010 inch gap between the edge of the strip and the

roller. If the rollers are set tightly against the strip, then servo drive overloads could result.

5.2 AUTO/MANUAL

MODE

When ‘MANUAL’ is selected via the 2-position selector switch, the control is put into ‘MANUAL MODE’. During

manual mode the feeder may be jogged infinitely in either direction.

Pressing ‘Cycle Start’ button, while the 2-position selector switch is in ‘AUTO MODE’ makes a servo feed ready to

accept an index signal from the press.