DE-STA-CO S/SM300A User Manual

Page 23

21

SECTION 6: Maintenance

6.1.

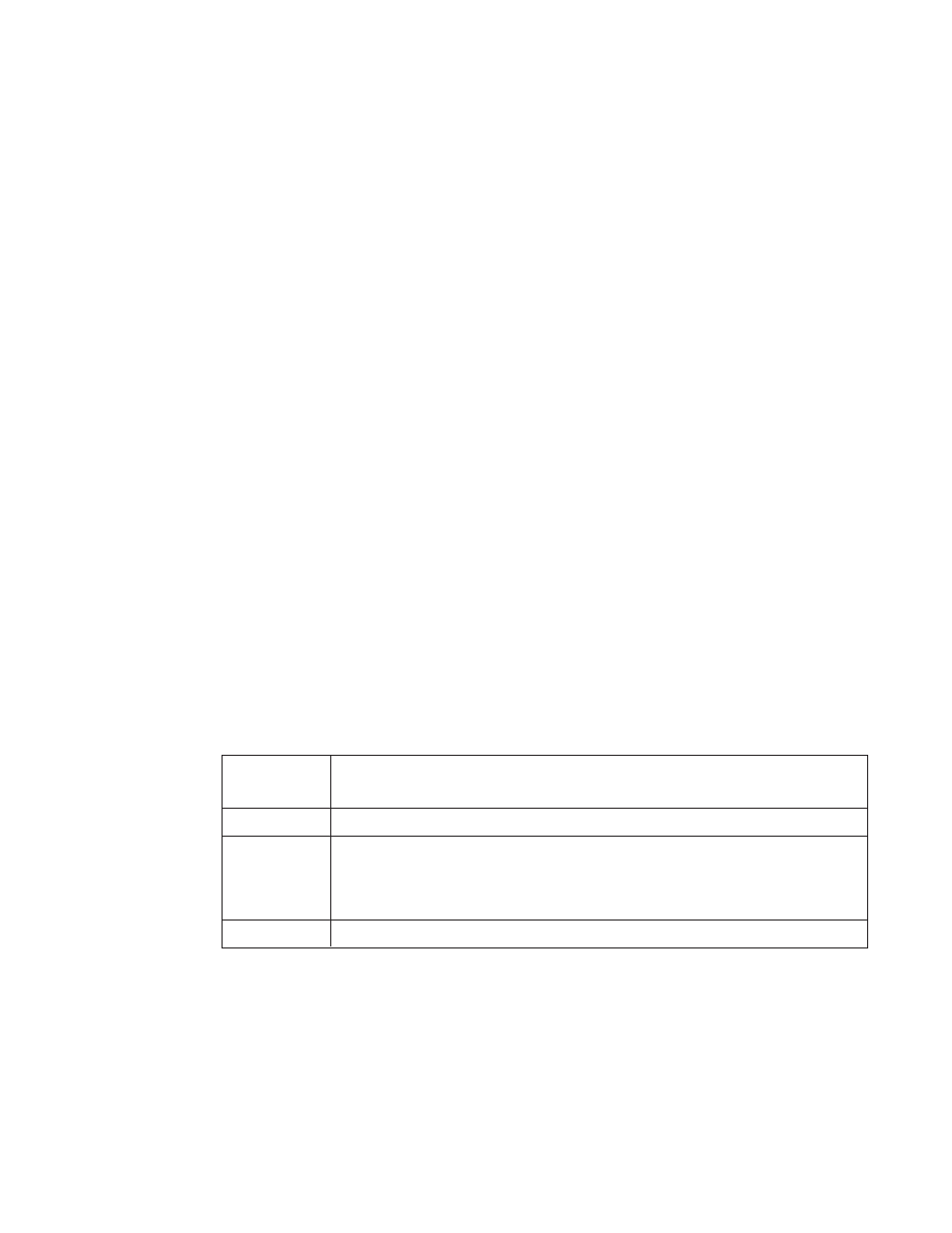

Correct Lubricants – For the protection of the unit use only lubricants meeting the

specifications shown below in Chart 2. If you have any questions about a particular

lubricant feel free to call us at 1-800-645-5207 or 847-459-5200.

6.2.

Changing Oil

6.2.1. All parts are oil splash lubricated except for isolated areas where grease fittings

will be supplied.

6.2.2. Maintain oil to the midpoint of the sight gauge or oil level & fill plug.

NOTE: The orientation of your unit will determine the exact quantity of oil

required.

6.2.3. Drain, flush and fill the unit in intervals of 2400 hours or at least yearly. If drive

operates at speeds above 300 RPM or at temperatures above 140 degrees F.,

increase oil change frequency to 6 months or 1200-hour intervals.

NOTE: When draining the oil observe for metal particles. This is an indication

of excessive wear and the source of this wear must be determined.

6.2.4. Service all grease fittings on 1-month intervals or every 200 hours of operation.

NOTE: In the majority of the applications, grease fittings are not supplied

since oil splash supplies the lubrication. Should grease be specified use

Lithium No.2.

Indexer Oil:

Use SAE 90 EP Gear oil or equivalent meeting MIL-PRF-2105E and

API Service Classification GL5 or GL6. For example, Mobilube HD 80W-90

Capacity:

See specifications in Chart 1 for your model.

Gear Oil:

Bronze Gear Reducer oil requires SAE 140 Steam Cylinder Oil,

meeting AGMA #8 Compound, MIL SPEC. MIL-L-15016A; symbol 3150

(Or manufacturer’s specified oil if not a Industrial Motion Control

manufactured reducer.)

Capacity:

See specifications in Chart 1 for your model.

CHART 2