DE-STA-CO S/SM300A User Manual

Page 21

19

SECTION 5: Adjustments (continued)

5.3.4. Clutch Adjustment Procedure

CAUTION: OPERATIING THE INDEXER WITH THE CLUTCH NOT ADJUSTED

CAN CAUSE IMMEDIATE AND SEVERE DAMAGE TO THE INTERNAL

COMPONENTS OF THE INDEXER.

a.

Loosen cone point setscrew (number 11, Figure 8).

b.

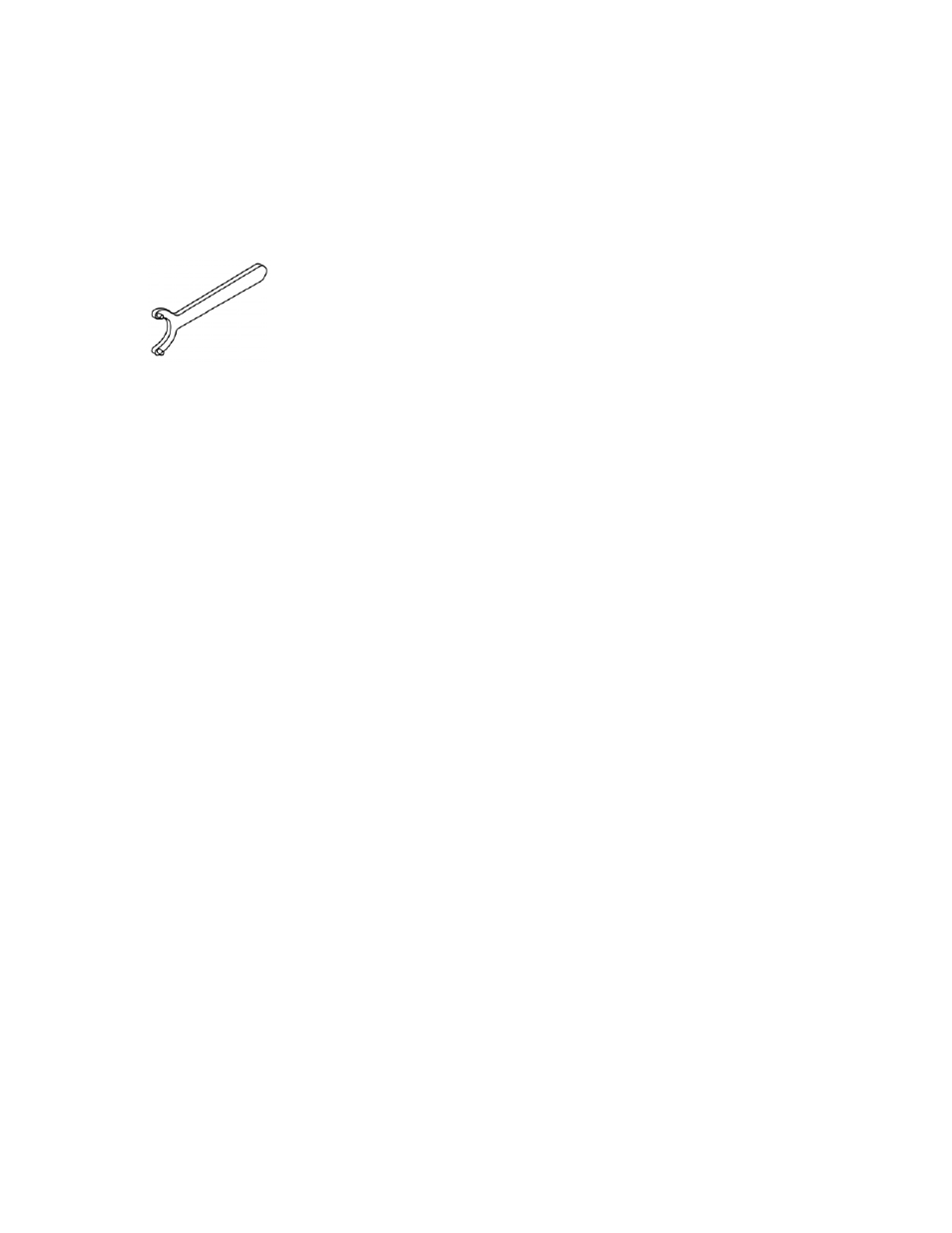

Insert pins of spanner (Figure 9) into holes of adjusting nut (number 6, Figure 8),

and turn nut clockwise one notch in the adjusting nut. This will tighten the clutch.

NOTE: For heavy indexing loads or clutches on large units, it may be

necessary to increase the length of the spanner wrench to gain more leverage.

If clutch has not been adjusted for a long period of time, it may be necessary

to turn the nut counter-clockwise several turns, and tap the face of housing

(number 1, Figure 8) towards the indexer with a rubber mallet to separate

(loosen) the tapers. Take note of the number of loosening turns so the

adjusting nut can be re-tightened to its original position.

c.

Re-tighten setscrew (number 11, Figure 8) making sure it engages in adjusting

nut (number 6, Figure 8) to prevent damage to screw threads.

NOTE: If setscrew (number 11, Figure 8) is accidentally tightened on

threaded portion of adjusting nut (number 6, Figure 8), it will raise a burr.

Failure to remove this burr will cause shearing of threads and jamming of nut

of housing (number 1, Figure 8). To remove burr, remove setscrew (number

11, Figure 8) and rotate adjusting nut counter-clockwise until burr is in center

of tapped hole in housing (number 1, Figure 8). Use a hand electric drill that

fits freely into the tapped hole. Drill into the adjusting nut (number 6, Figure 8)

sufficiently to remove the burr.

There are (2) setscrews (number 11, Figure 8). They are positioned so one

screw is half way between the slots in the nut when the other screw engages

the slot in the nut. This is to allow for fine adjustment of the clutch. DO NOT

use both screws at the same time as one screw will not be over a slot and will

cause damage to the screw threads.

FIGURE 9