0 installation, Caution, Table 1 – Bray Triple Offset User Manual

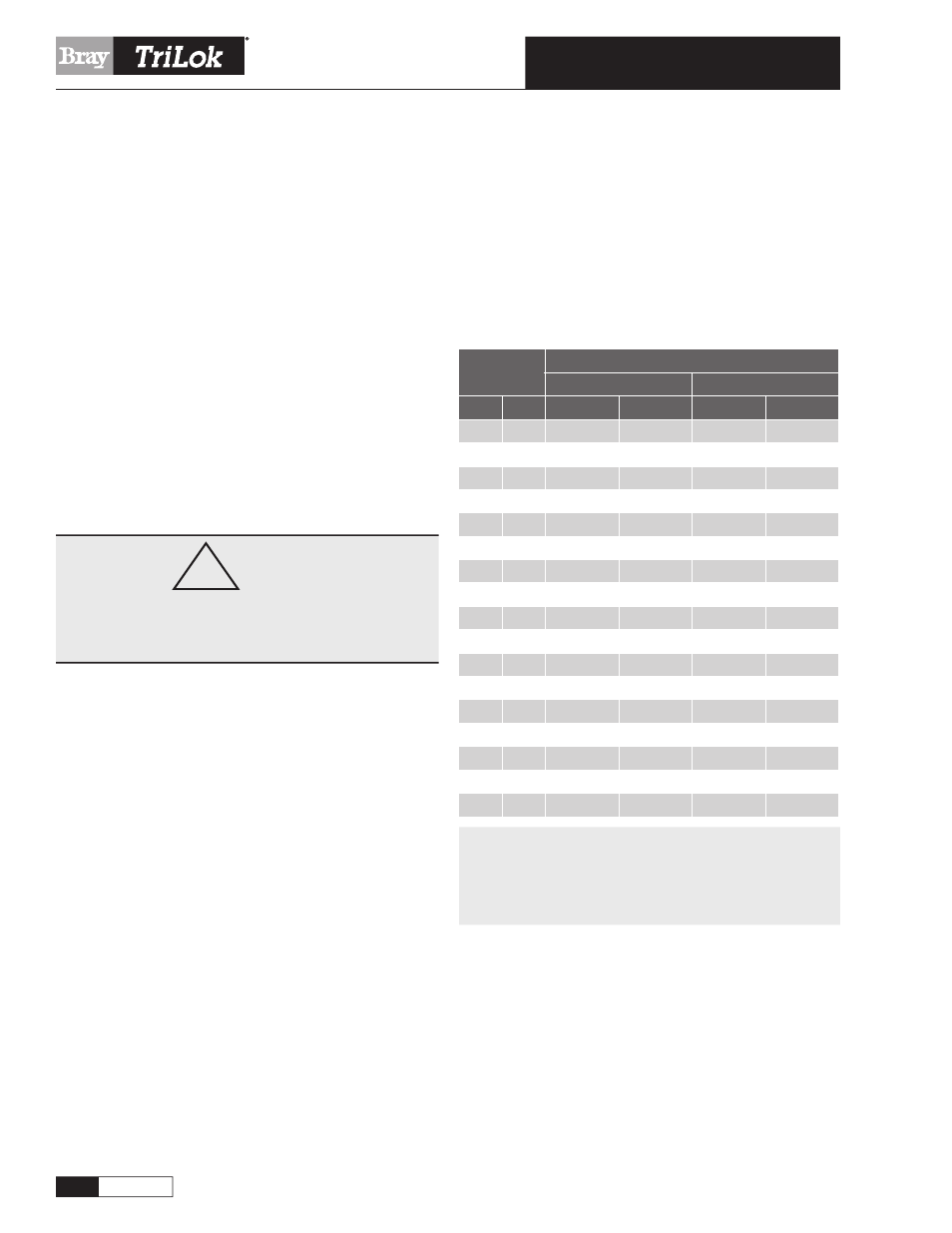

Page 6: Minimum allowable pipe id for tri lok installation

A D i v i s i o n o f B r a y I n t e r n a t i o n a l , I n c .

The Ultimate Critical Service Triple Offset Valve

O p e r a t i o n a n d M a i n t e n a n c e M a n u a l

4

O & M

Notes for Table 1

s

s

s

face of the valve body.

3.0 Installation

1. Tri Lok is designed to be installed between ASME

is open, a portion of the disc may protrude into the

and some gate sizes, the open disc may protrude into

the pipe on the seat side of the valve. Adjacent piping

must be large enough to allow the open disc to clear

the pipe.

Table 1 shows the minimum allowable pipe ID. In

general, Class 150 valves will clear Schedule 40 pipe,

and Class 300 will clear Schedule 80 pipe without

interference.

2. The valve closes with clockwise rotation of the stem,

and opens with counterclockwise rotation.

!

CAUTION

Avoid uncontrolled rotation of the disc beyond fully-

open position (counterclockwise) as this could damage

the sealing surfaces.

torque and best sealing conditions, install the valve

with the stem on the upstream (pressure side) of the

installation. The valve tag is marked with an arrow

4. Whenever possible, install with the stem in horizontal

position with respect to the ground. If this installation

is not possible, orient the stem at an inclined angle,

with the actuator above the horizontal centerline. This

will prevent debris from accumulating in the bearing

area. With the valve stem horizontal, the weight of

the disc will be supported along the full length of the

bearing journals; thus minimizing operational wear.

5. Flange gaskets should conform to the requirements

of ASME B16.20 (supersedes API Standard 601) for

Flexitallic

®

CG or CGI series, conforming to ASME

B16.20 are recommended.

(

Flexitallic

®

is a registered trademark of The FDS Group)

6. When bolting the valve into the line, use standard

bolting torque as recommended by applicable pip-

ing standards. The valve body seat (replaceable) is

Table 1

Minimum Allowable Pipe ID for Tri Lok Installation

Valve/Pipe

Size

Minimum Pipe ID

Class 150

Class 300

In

mm

In

mm

In

mm

3

80

2.3

51

2.3

51

4

100

3.3

78

3.3

78

6

150

5.3

128

5.1

121

8

200

7.0

172

6.8

165

10

250

8.9

221

8.9

219

12

300

10.9

270

10.9

277

14

350

12.1

300

11.6

294

16

400

14.1

350

13.5

335

18

450

15.9

392

15.3

381

20

500

17.7

450

17.1

427

24

600

21.5

540

21.1

267

30

750

26.9

684

26.7

677

32

800

29.1

740

–

–

36

900

33.1

841

32.6

828

40

1000

36.6

929

–

–

42

1050

38.7

982

37.5

951

48

1200

44.6

1134

43.2

1096