Table 5, Table 6 torque values for gland retaining cap nuts, Table 7 – Bray Triple Offset User Manual

Page 19

17

O & M

ASME CLASS

600 & 900

A D i v i s i o n o f B r a y I n t e r n a t i o n a l , I n c .

The Ultimate Critical Service Triple Offset Valve

O p e r a t i o n a n d M a i n t e n a n c e M a n u a l

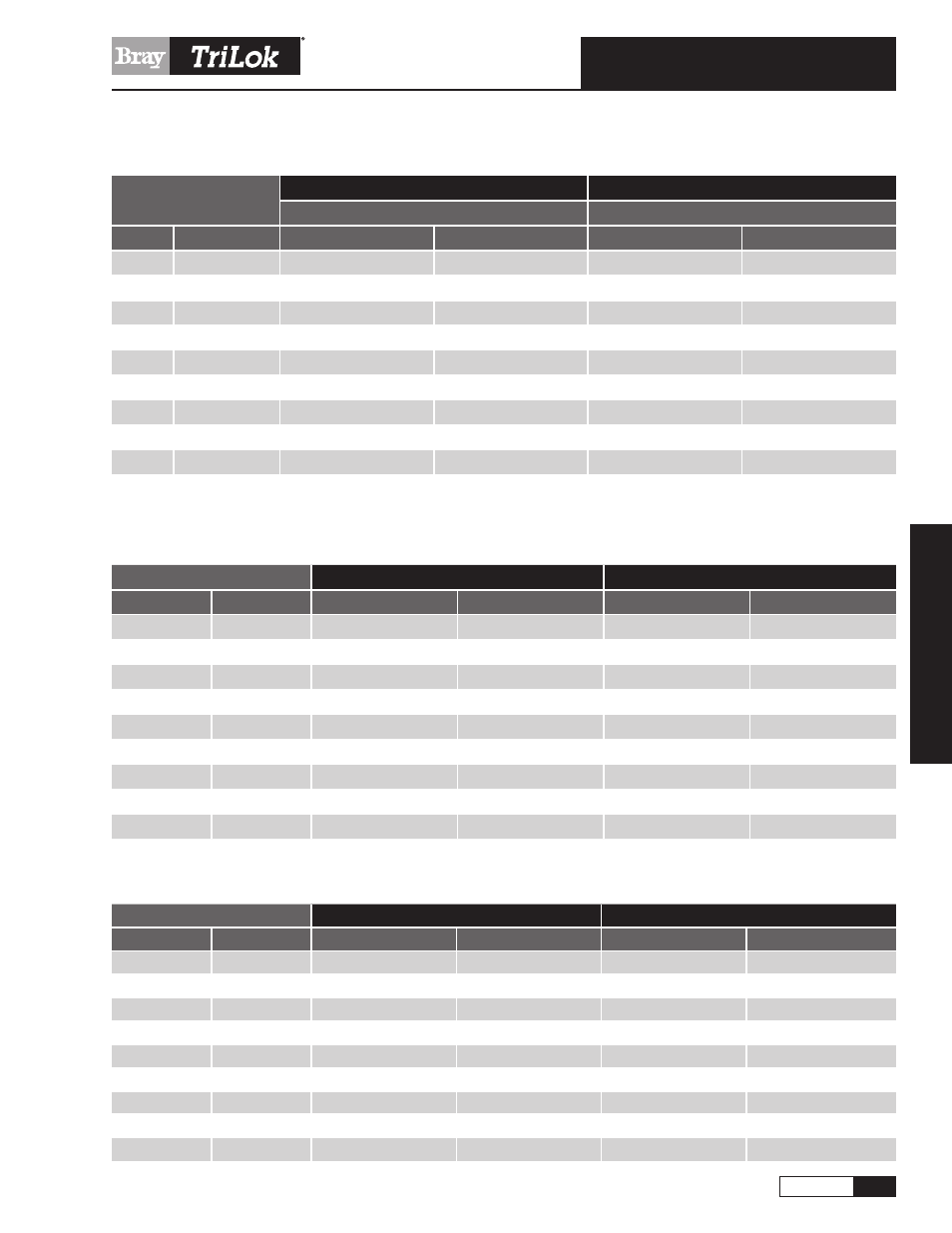

Table 5

Torque Values for Seat Retaining

Valve Size

Class 600

Class 900

Seat Lower Dowel Fastener*

Seat Lower Dowel Fastener*

in

mm

Lb-in

Nm

Lb-in

Nm

4

100

65 - 90

7-10

-

-

6

150

180 - 225

20-25

310 - 350

35-40

8

200

265 - 310

30-35

310 - 350

35-40

10

250

265 - 310

30-35

310 - 350

35-40

12

300

265 - 310

30-35

-

-

14

350

530 - 575

60-65

-

-

16

400

530 - 575

60-65

850 - 950

95-105

18

450

530 - 575

60-65

850 - 950

95-105

20

500

-

-

1240 - 11420

140-160

*Seat upper dowels require 1/3 the torque of the seat lower dowel fasteners.

Table 6

Torque Values for Gland Retaining Cap Nuts

Valve Size

Class 600

Class 900

in

mm

Lb-in

Nm

Lb-in

Nm

4

100

130 - 155

15-17.5

-

–

6

150

265 - 310

30-35

265 - 310

30-35

8

200

265 - 310

30-35

620 - 750

70-85

10

250

490 - 530

55-60

750 - 840

80-95

12

300

620 - 750

70-85

-

-

14

350

620 - 750

70-85

-

-

16

400

750 - 840

80-95

1685 - 1815

190-205

18

450

1110 - 1240

125-140

1685 - 1815

190-205

20

500

-

-

1685 - 1815

190-205

Table 7

Torque Values for Bottom Flange Screws

Valve Size

Class 600

Class 900

in

mm

Lb-in

Nm

Lb-in

Nm

4

100

265 - 310

30-35

-

-

6

150

350 - 400

40-45

1240 - 1285

140-145

8

200

350 - 400

40-45

1860 - 1995

215-225

10

250

1240 - 1285

140-145

1860 - 1995

215-225

12

300

1240 - 1285

140-145

-

-

14

350

1860 - 1995

215-225

-

-

16

400

1860 - 1995

215-225

2560 - 2650

290-300

18

450

2560 - 2650

290-300

2560 - 2650

290-300

20

500

-

-

2560 - 2650

290-300