Bray Triple Offset User Manual

Page 18

16

O & M

ASME CLASS

600 & 900

A D i v i s i o n o f B r a y I n t e r n a t i o n a l , I n c .

The Ultimate Critical Service Triple Offset Valve

O p e r a t i o n a n d M a i n t e n a n c e M a n u a l

3. Loosen up all the disc seal ring retaining cap screws

(C8) but leave them in the valve with the disc seal

ring retainer (C7) attached to the disc (C1).

4. Completely open the valve, remove the disc seal

ring retaining cap screws (C8), extract the disc seal

ring retainer (C7) and the disc seal ring with collar

(C2 & C3) making sure not to damage the seat.

If it’s necessary, open the valve past 90° to easily

remove the seal retainer and disc seal ring. Using

soft tools and a suitable wire brush, carefully clean

any remnants of old gasket and foreign matter from

the face of the disc (C1). Blow out all threaded

holes and the gasket groove with compressed air.

remove any small scratches or product deposits (if

any).

6. Rotate the disc (C1) to it’s previous position to

facilitate installation of the disc seal ring (C2).

Place a new disc seal ring gasket (C3) into the

groove on the disc face (C1). The mating side of

the disc seal ring gasket can be lightly greased to

improve retention in the groove. Be sure that the

new disc seal ring (C2) is assembled with the disc

seal ring collar (C3) and kept together with the disc

seal ring collar pin (C4). Place the disc seal ring and

collar onto the disc making sure the collar groove

is aligned with the disc seal ring reference button

(C6). Place the disc seal ring retainer (C7) over the

disc seal ring. Apply anti-seize compound to the

disc seal ring retaining cap screws (C8). All of the

cap screws (C8) need to be fully threaded into the

Lubricate the sealing surfaces of the disc seal ring

(C2) and the body seat (replaceable) (B1).

7. Cycle the valve with the actuator 2-3 times, only

closing the valve to the point where the disc seal

ring engages with the seat. Check each time that

the disc seal ring makes full contact with the body

seat (replaceable) without torquing into the seat.

Attention should be paid in the closing stroke that

the body seat (replaceable) does not scratch the disc

seal ring. This will allow the disc seal ring and seat

to be properly aligned. Tighten at least four screws

in the seal retainer to prevent the disc seal ring from

further movement. Open the valve approximately

seal ring, disc seal ring retainer) are aligned. Tighten

the disc seal ring retainer cap screws (C8) using

a cross bolting technique, to the 50% of torque

Table 4 (Pg. 16). Once all screws

are tightened at the same torque, proceed to fully

tighten them to 100% of the listed torque value.

8. Remove the gearbox (if installed), mount the valve

actuator and test the valve.

11.4 Bottom Flange Gasket Replacement

-

ence numbers. (Pg 13).

1. If the valve is installed, remove line pressure.

2. Completely remove the bottom plate screws (G3).

Remove the bottom plate (G1) and the bottom plate

gasket (G2).

3. Clean the bearing area of residual gasket and for-

eign materials. Grease the body/bottom plate gasket

groove area.

4. Place the new gasket (G2) on the bottom plate (G1)

and install it onto the body.

5. Reinstall the bottom plate screws (G3) and using the

cross bolting technique, tighten them according to

Table 7 (Pg. 17).

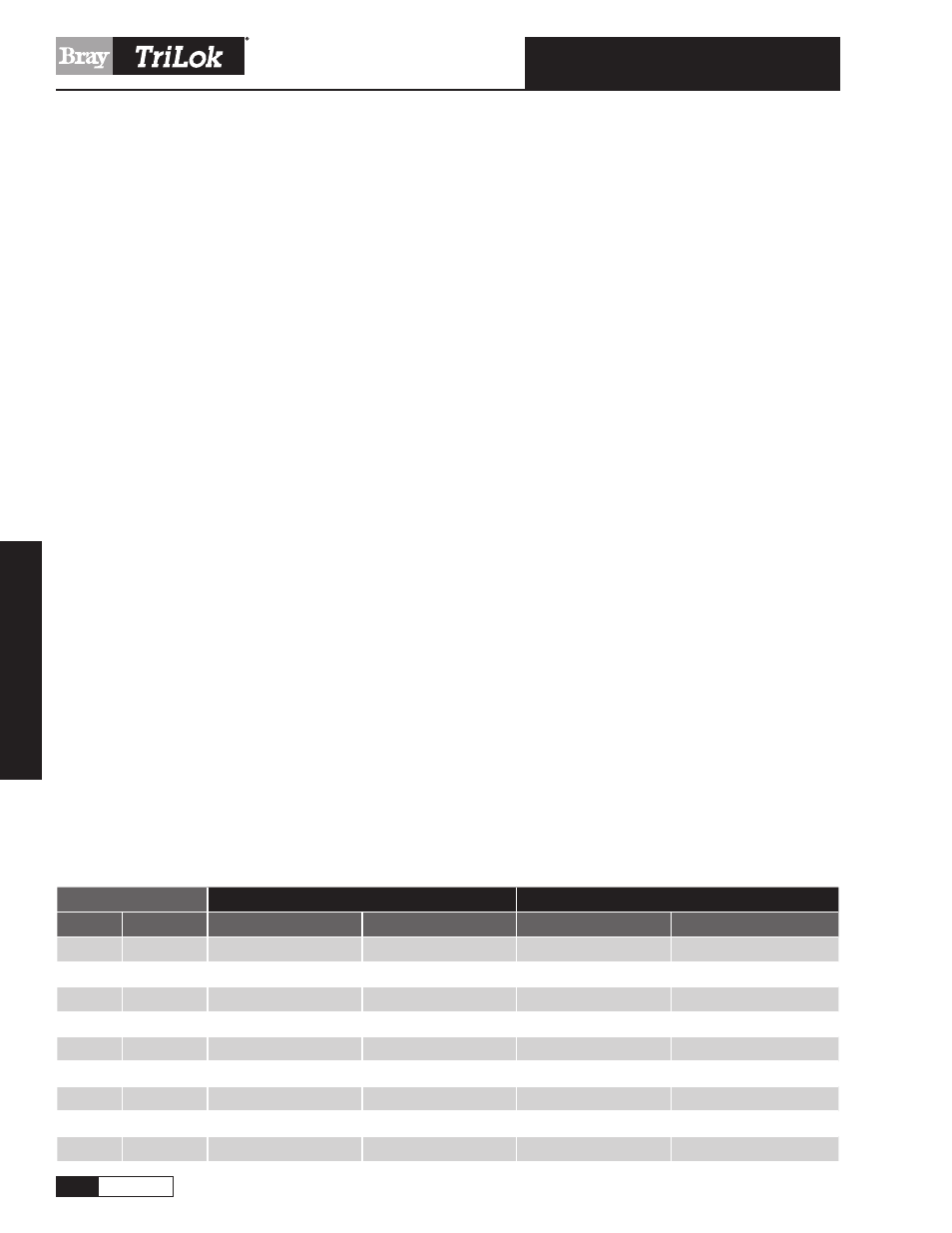

Table 4

Torque Values fordisc seal ring Retaining Cap Screws

Valve Size

Class 600

Class 900

in

mm

Lb-in

Nm

Lb-in

Nm

4

100

142 - 185

16 - 20

-

–

6

150

265 - 310

30 - 35

310 - 350

35 - 40

8

200

265 - 310

30 - 35

490 - 530

55 - 60

10

250

795 - 885

90 - 100

1000 - 1120

115 - 130

12

300

795 - 885

90 - 100

-

-

14

350

795 - 885

90 - 100

-

-

16

400

795 - 885

90 - 100

1000 - 1120

115 - 130

18

450

1685 - 1815

190 - 205

1860 - 1995

215 - 225

20

500

-

-

1860 - 1995

215 - 225